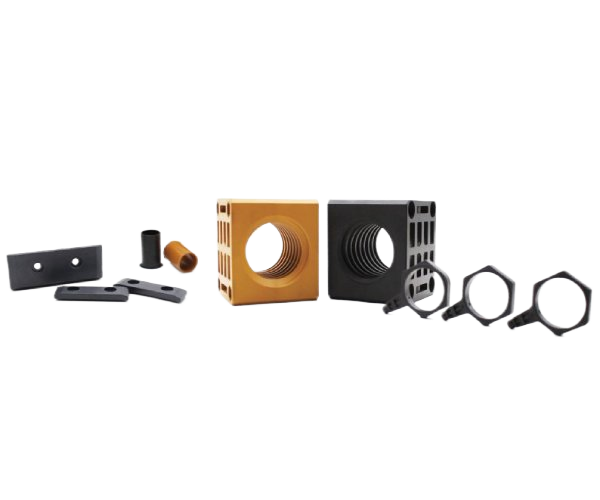

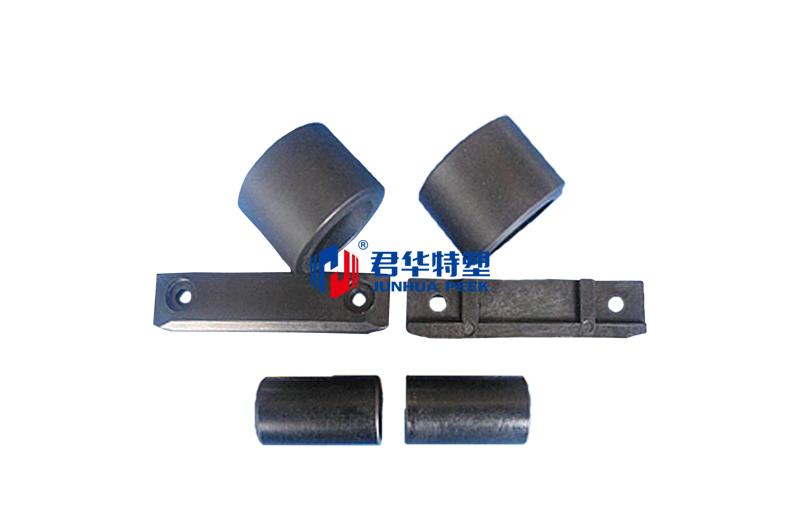

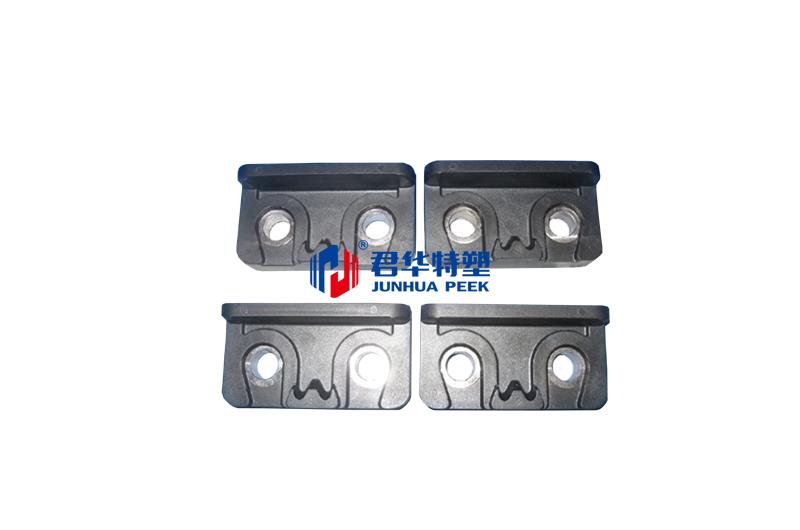

PEEK components—chain sliders, bushings, wear strips, guards, and valve spools—deliver high temperature capability (up to 250 °C), outstanding wear and chemical resistance, and self‑lubricating, low‑friction operation.

PEEK significantly improves line efficiency and uptime while lowering total cost of ownership—ideal for stenters, dyeing machines and hot‑air dryers.

Stable performance up to 250 °C continuous service for hot processes and long duty cycles.

Excellent tribology and resistance against common textile chemicals and dyes for fewer changeovers.

Low friction, dry‑running capability helps reduce lubrication points, noise and maintenance.

Supply of PEEK pellets, rods, sheets and machined / injection‑moulded parts. Send drawings or sample photos—we’ll advise material grades and tolerances for textile duty.

Continuous operation up to around 250 °C depending on grade and loading. Ideal for stenter hot zones and dryers.

Yes—PEEK exhibits self‑lubricating behavior and a low coefficient of friction, which helps reduce oiling points and contamination risk.

PEEK offers excellent resistance to many solvents, acids and alkalis commonly used in dyeing and finishing lines.

We provide both CNC‑machined and injection‑moulded PEEK parts. Send your drawings to receive DFM suggestions and quotes.

Junhua offers one-stop PEEK solutions from design to after-sales, ensuring quality, innovation, and customer satisfaction.

Junhua offers injection molding, machining, and extrusion solutions to optimize design and cost.

Junhua specializes in PEEK with multiple grades and recommends the best engineering plastics for your needs.

Junhua uses high-precision instruments to provide customers with accurate drawings.

Junhua supplies samples for testing and refines designs until approval for mass production.

Junhua controls raw materials, processes, and inspections to ensure consistent product quality.

Junhua follows ISO9001 standards and provides full inspection reports as required.

Junhua continuously optimizes designs and processes through improvement systems and case experience.

Junhua offers complete after-sales support to resolve technical issues and protect customer interests.

Junhua was founded in 2007 and specializes in the development, production, and sale of high-performance engineering plastics, particularly PEEK, PI, PPSU, and other special polymers. The company has a modern factory occupying 15,000+ square meters , with 40+ extrusion lines ,Complete injection molding and CNC processing equipment, with an annual production capacity of over.

We have obtained multiple international certifications such as AS9100D (Aerospace), ISO9001, IATF1649 (Automotive), ISO13485 (Medical Devices), FDA, RoHS, REACH, SGS , and our products are fully traceable . Our customers cover multiple high-threshold industries in over 60 countries and regions , including aerospace, medical, semiconductor, electronics, food, and new energy vehicles. We are committed to becoming a global leader in PEEK solutions.

27 Utility Model Patents

40+ Extrusion Lines + Cleanroom

30000+ Global Customers | 300 Million+ RMB Sales

18+ Years of Experience | 40+ Global Employees

AS9100D / ISO13485 / IATF16949 etc.

Serve 60+ Countries

Contact Us Now and Enjoy a One-Stop Solution!Fill the Form to Get a Quote, Product Manual, Performance Parameters, Custom Solutions, Technical Consultation, and Samples