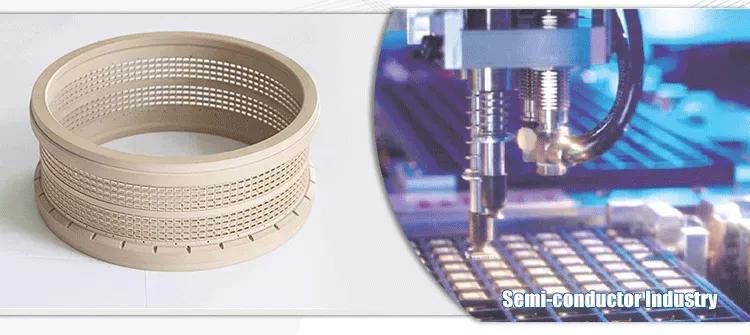

PEEK Solutions across Electronic Industry

PEEK Solutions across Electronic Industry

PEEK is widely used on consumer electronics, home appliances and semiconductor products for

electronic industry. PEEK polymers can withstand continuous use high temperatures and harsh

chemicals, modified peek provide a range of electrically conductive, anti-static or static

dissipative properties, these characteristics are important for semi-conductor applications

such as vacuum traceless sucker.

JUNHUA® PEEK solution to suit every environment and meets the strictest requirements, based

components have a proven cost less than traditional materials, such as replacing metal with

integrated PEEK components can improve energy efficiency in appliances up to 2% by weight

reduction, help increase fab productivity up to 3% with longer lifetime than PPS.

Team up with JUNHUA® PEEK to address your challenges in the ever-changing electronics

industry.

Explore our PEEK-type Solutions

Explore our PEEK-type Solutions

PEEK has many advantages in the field of electrical semiconductors:

- Very high temperature resistance (up to 260°C continuous operating temperature)

- Excellent chemical resistance

- Good dimensional resistance (low thermal expansion)

- Optimal ratio of stiffness, solidity, toughness and minimal tendency to creep

- Very good tribological properties

- Good radiation resistance

- Excellent resistance to hydrolysis

- Fire performance: flame-retardant, Low smoke density, No toxic gases

- Good machinability

- Good bondability and weldability

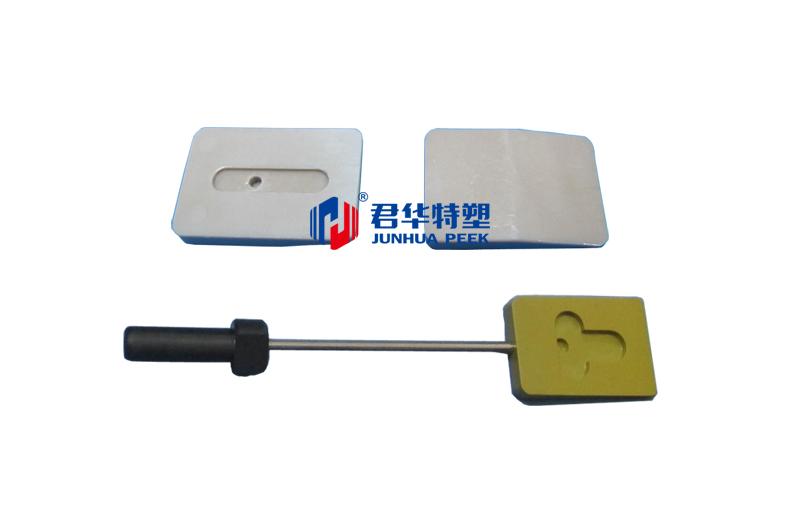

Typical product: PEEK chip clip, PEEK vacuum sucket, CMP ring, PEEK vaccum tweezer, PEEK screw

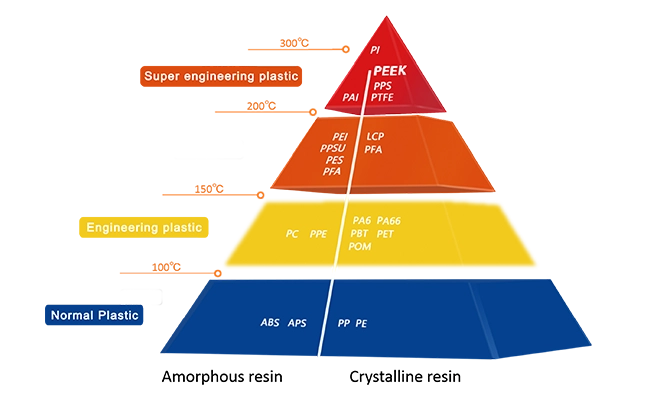

What is PEEK?

PEEK and its modified composite materials show excellent performance under high temperature and high humidity conditions. PEEK have excellent chemical corrosion resistance, self-lubricating, and wear-resistant properties, so it has become the most ideal material to replace copper alloys and ordinary rubber. Compared with them, PEEK has longer service life which can reduce equipment operating costs, improve equipment operating reliability.

High Temperature Performance

PEEK's performance can remain stable in the temperature range from -196°C to 260°C. Under extreme working conditions, it can withstand 300"C for a short time. The performance of PEEK is still reliable even in high temperatures of several kilometers underground work environment.

High Strength and Wear Resistance

Compared with other plastics, PEEK is resistant to compression, impact and also have good fatigue resistance. PEEK is durable in mechanical equipment and wear-resistant environments.

Double the Service Life

PEEK sealing solutions can improve the part service life. Some domestic chemical companies use the PEEK5600FE20 polytetrafluoroethylene modified material designed by Junhua to replace the original material, the service life of the wear parts can even be extended by 1.3-3 times.

Corrosion Resistance

PEEK is chemically inert, and has no reaction to most acids, oils, greases and all other organic and inorganic solvents or enzymes, and can still maintain good strength and dimensional stability.

Self-lubricating

PEEK has low friction coefficient, low running resistance, can be used without oil in some working conditions. The equipment is cleaner, thus improving process reliability, improving energy efficiency and saving costs.

More dom in Design

Injection molds can be used for rapid injection molding of large quantities of complex special-shaped parts, and the cost is low compared to machining.

PEEK Material and Types of it's Modification

PEEK5600G (unfilled PEEK or natural PEEK)

PEEK5600G is one of unfilled or natural PEEK.Outstanding chemical resistance and a high operating temperature (up to 250℃/480F) round out PEEK profile.PEEK5600G has excellent dimensional stability combined with high creep stability, ensuring the suitability of PEEK for the most sophisticated machined parts.

PEEK5600GF30 ( 30% glass fiber filled PEEK)

Compared with unfilled PEEK(PEEK5600G),this 30% glass fiber reinforced PEEK material(PEEK5600GF30) exhibits increased mechanical strength and high rigidity.Plus, improved creep strength and dimensional stability are delivered by the 30% glass fiber filled PEEK.

PEEK5600CF30 (30% carbon fiber filled PEEK)

PEEK5600CF30 is a 30% carbon filled PEEK material that is manufactured by Junhua. Its carbon fiber reinforcement supports the material a high level of rigidity. Carbon fiber reinforced PEEK demonstrates very high mechanical strength values.

PEEK5600LF30( HPV PEEK or bearing grade PEEK)

PEEK5600LF30 black is developed especially for bearing and sliding applications. HPV PEEK is based on a PEEK polymer that has been modified with 10% each of PTFE, graphite and carbon fibres. It combines the properties of a high-grade matrix material with special, wear-improving additives.

Contact Us

Products

M4 PEEK screw

PEEK Flat Wire

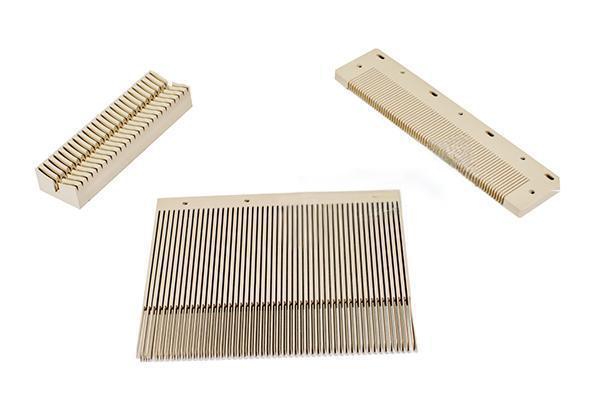

PEEK comb teeth

PEEK wafer clamp

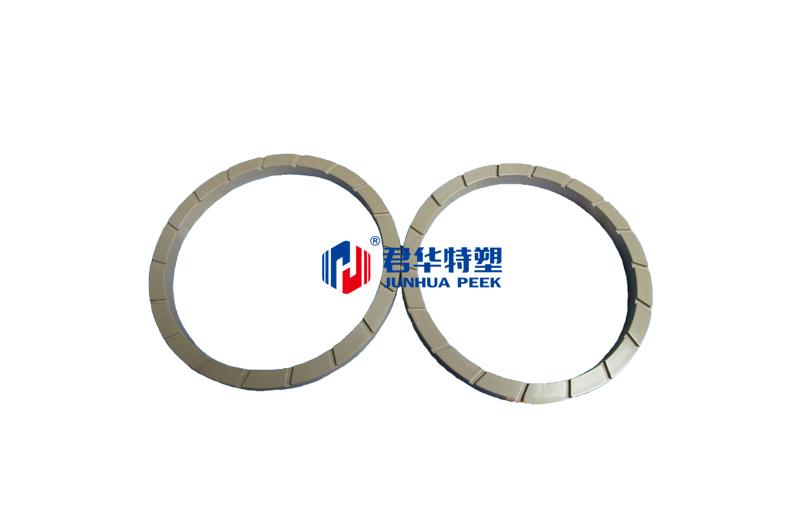

PEEK grinding ring

PEEK, PAI vacuum pen tip

CASE STUDY - CMP Ring

CASE STUDY - CMP Ring

CASE STUDY - CMP Ring

A very important step in silicon wafer production is the Chemical Mechanical Planarization (CMP) process. The trend is towards larger wafer sizes, smaller chips with narrower line widths and feature sizes. The challenge is to find a material with the desired characteristics, as the CMP process requires components made of highly qualified materials. In close cooperation with customers, we have specialised in developing materials that meet these requirements.

Product Processing and Quality Control Capability

Product Processing and Quality Control Capability

Cool Jet dry ice deburring equipment lmprove the quality of machined parts

- Non-dastuntive cleanina;

- Improve product quality and reduce-scrap rate;

- No manual removal of burrs and Haps;

- No secondary waste;

- Faster and more uniform removal of bums and flaps.

Dry ice cleaning technology is an effective deburring solution for removing burrs and flaps from machined and modeled parts. Including small holes, cross holes,pollution-, can effectively prevent the pipeline flow reduction or blockage caused by burrs, and no residue.

100,000-level cleaning workshop

Our company has established a 280-square-meter, 100,000-level cleaning workshop and equipped with 100-level cleaning area accordance with GMP requirements.

Certificate