PEEK Tube

PEEK is a high-performance thermoplastic that is tough, durable, firm, and creep resistant.

It offers excellent thermal, chemical, and hydrolysis resistance as well as excellent

resistance to abrasion and dynamic fatigue. Its ability to run at high continuous

temperatures up to (250º C) without permanent property degradation along with stable

electrical properties makes PEEK an excellent alternative to fluoropolymers in aggressive

environments. PEEK has also been shown to exhibit very low smoke and toxic gas emission when

exposed to flame.

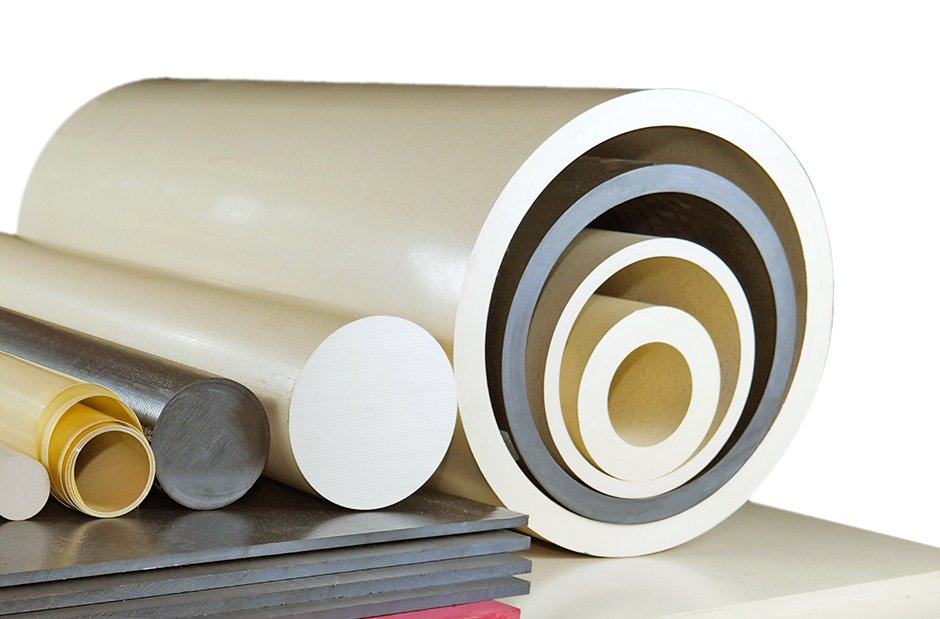

Among all the round PEEK finished part widely used in different industries, nearly half are

hollow, which makes PEEK tube a much favorable choice compared with rod especially in the

oil and gas, or semiconductor industry.

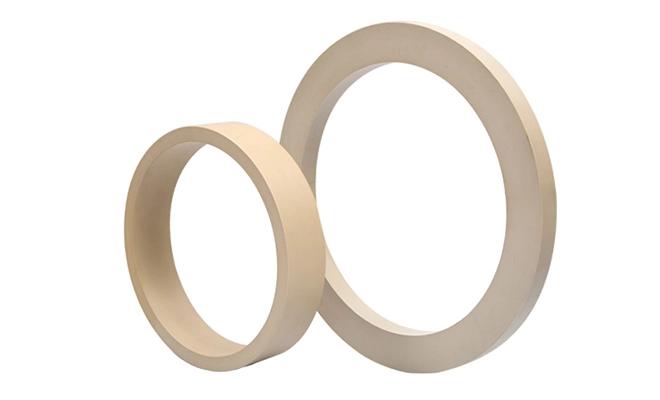

Junhua specializes in various processing methods to achieve the capability of

producing PEEK tubes and rings for a wide range of dimensions. we produce PEEK tubes and

rings through extrusion, compression molding, and injection molding. All processes offer a

wide range of sizes that can be tailored to the customer's needs.

With totally over 300 sizes,Junhua can offer PEEK tube with OD range from 10mm to

1200mm,and we keep ready stock of the over 200 sizes most commonly used PEEK tubes to ensure

the fast delivery to our customers around the world.

Main Advantages of PEEK Tube

- ● Good wearing performance with or without load

- ● High service temperature(long term 260C

- ● Good mechanical strength

- ● Good chemical resistance & Hydrosis resistance

- ● FDA approved

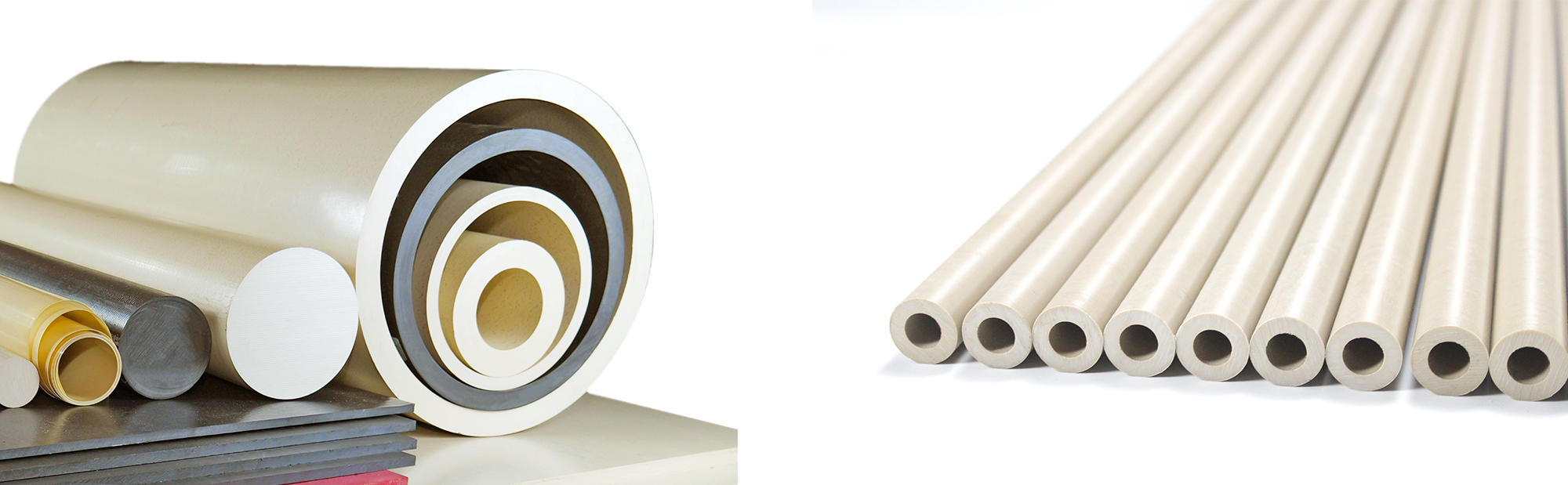

PEEK Extrusion Production Line

PEEK Extrusion Production Line

PEEK Tubes: Outer Diameter 23~550mm × Inner Diameter 12~460mm (Customizable length available upon request). (If the above specifications are not suitable, we can supply products of any size, length, and width specification, and zero-cut them accordingly).

Higher Production Efficiency

Comprehensively improve PEEK rod production efficiency, which can be increased by 300-400% of the original, achieving the goal of ensuring customer order delivery and improving customer satisfaction.

More Stable Quality

Automated production greatly reduces the impact of other factors on production. The large-volume production of PEEK rods is stable and reliable, with advantages in color, appearance, and internal quality in both domestic and international markets.

Lower Loss and Production Cost

The new equipment systematically saves production time, labor, and maintenance costs, improving every aspect of the original production process to achieve lower loss and production costs.

Junhua has been continuously expanding its manufacturing capabilities for PEEK products, introducing advanced production lines and technology to optimize the factory's PEEK production. With more advanced R&D technology and processing capabilities, Junhua will provide you with higher quality, more cost-effective PEEK products and better product solutions, to push PEEK towards a broader and brighter future!

PEEK Extruded Tube Specifications Table

| No. |

Outer Diameter × Inner Diameter OD×ID (mm) |

OD Tolerance (mm) |

ID Tolerance (mm) |

Roundness Tolerance (mm) |

|---|

PEEK Material and Types of it's Modification

PEEK5600G (unfilled PEEK or natural PEEK)

PEEK5600G is one of unfilled or natural PEEK.Outstanding chemical resistance and a high operating temperature (up to 250℃/480F) round out PEEK profile.PEEK5600G has excellent dimensional stability combined with high creep stability, ensuring the suitability of PEEK for the most sophisticated machined parts.

PEEK5600GF30 ( 30% glass fiber filled PEEK)

Compared with unfilled PEEK(PEEK5600G),this 30% glass fiber reinforced PEEK material(PEEK5600GF30) exhibits increased mechanical strength and high rigidity.Plus, improved creep strength and dimensional stability are delivered by the 30% glass fiber filled PEEK.

PEEK5600CF30 (30% carbon fiber filled PEEK)

PEEK5600CF30 is a 30% carbon filled PEEK material that is manufactured by Junhua. Its carbon fiber reinforcement supports the material a high level of rigidity. Carbon fiber reinforced PEEK demonstrates very high mechanical strength values.

PEEK5600LF30( HPV PEEK or bearing grade PEEK)

PEEK5600LF30 black is developed especially for bearing and sliding applications. HPV PEEK is based on a PEEK polymer that has been modified with 10% each of PTFE, graphite and carbon fibres. It combines the properties of a high-grade matrix material with special, wear-improving additives.

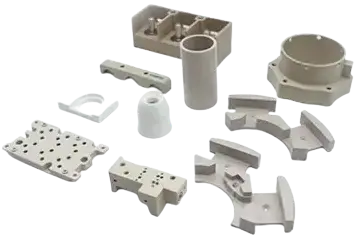

PEEK Solutions

Contact Us

PEEK Typical Data

| Item | Standard | Data | Units |

| Color | - | Natural | |

| Density | ISO 1138 | 1.3±0.01 | g/cm3 |

| Water Absorption (25℃.24Hrs) | ISO 62 | 0.05 % | |

| Melting temperature | ISO 11357 | 343 | ℃ |

| Distortion Temperature | ISO 75-1/-2 | 163 | ℃ |

| Continuous service Temperature | UL 74685 | 260 | ℃ |

| Thermal expansion coefficient | ASTM D696 | 4.7*10-6 | /K |

| Tensile Strength (23℃) | ISO 527 | 100 | MPa |

| Tensile modulus (23℃) | ISO 527 | 3.8 | GPa |

| Tensile Elongation (23℃) | ISO 527 | 27 % | |

| Bending Strength (23℃) | ISO 178 | 163 | MPa |

| Bending Modulus (23℃) | ISO 178 | 3.5 | GPa |

| Impact Strength(23℃) | ISO 604 | 123 | MPa |

| Lzod Impact Strength (No notched) | ISO 180/U | No Break | kJ/m2 |

| Poisson Ratio | ISO 527-2 | 0.4 | |

| Rockwell Hardness | GB3398.2 | 118 | |

| Flammability | UL 94 (1.5 mm) | V-0 | |

| Dielectric strength | IEC 60243-1 | 18 | KV/mm |

| Dielectric constant | IEC 60250 | 3.2 | |

| Thermal Conductivity | ISO 22007 | 0.28 | W/(m·K) |

| Surface Resistance | IEC 90093 | 1015 | Ω |

| Item | Standard | Data | Units |

| Color | - | Black | |

| Density | ISO 1138 | 1.4±0.03 | g/cm3 |

| Water Absorption (25℃.24Hrs) | ISO 62 | 0.05 % | |

| Melting temperature | ISO 11357 | 343 | ℃ |

| Distortion Temperature | ISO 75-1/-2 | 315 | ℃ |

| Continuous service Temperature | UL 74685 | 260 | ℃ |

| Thermal expansion coefficient | ASTM D696 | 1.5*10-6 | /K |

| Tensile Strength (23℃) | ISO 527 | 125 | MPa |

| Tensile modulus (23℃) | ISO 527 | 9.3 | GPa |

| Tensile Elongation (23℃) | ISO 527 | 2.5 % | |

| Bending Strength (23℃) | ISO 178 | 271 | MPa |

| Bending Modulus (23℃) | ISO 178 | 9.1 | GPa |

| Impact Strength(23℃) | ISO 604 | 196 | MPa |

| Lzod Impact Strength (No notched) | ISO 180/U | 38 | kJ/m2 |

| Poisson Ratio | ISO 527-2 | 0.35 | |

| Rockwell Hardness | GB3398.2 | 123 | |

| Flammability | UL 94 (1.5 mm) | V-0 | |

| Dielectric strength | IEC 60243-1 | - | KV/mm |

| Dielectric constant | IEC 60250 | - | |

| Thermal Conductivity | ISO 22007 | 0.95 | W/(m·K) |

| Surface Resistance | IEC 90093 | 105 | Ω |

| Item | Standard | Data | Units |

| Color | - | Natural | |

| Density | ISO 1138 | 1.5±0.01 | g/cm3 |

| Water Absorption (25℃.24Hrs) | ISO 62 | 0.05 % | |

| Melting temperature | ISO 11357 | 343 | ℃ |

| Distortion Temperature | ISO 75-1/-2 | 315 | ℃ |

| Continuous service Temperature | UL 74685 | 260 | ℃ |

| Thermal expansion coefficient | ASTM D696 | 2.2*10-6 | /K |

| Tensile Strength (23℃) | ISO 527 | 110 | MPa |

| Tensile modulus (23℃) | ISO 527 | 7.9 | GPa |

| Tensile Elongation (23℃) | ISO 527 | 3.5 % | |

| Bending Strength (23℃) | ISO 178 | 214 | MPa |

| Bending Modulus (23℃) | ISO 178 | 7.5 | GPa |

| Impact Strength(23℃) | ISO 604 | 142 | MPa |

| Lzod Impact Strength (No notched) | ISO 180/U | 41 | kJ/m2 |

| Poisson Ratio | ISO 527-2 | 0.35 | |

| Rockwell Hardness | GB3398.2 | 122 | |

| Flammability | UL 94 (1.5 mm) | V-0 | |

| Dielectric strength | IEC 60243-1 | 17 | KV/mm |

| Dielectric constant | IEC 60250 | 3.4 | |

| Thermal Conductivity | ISO 22007 | 0.31 | W/(m·K) |

| Surface Resistance | IEC 90093 | 1015 | Ω |

| Item | Standard | Data | Units |

| Color | - | Black | |

| Density | ISO1138 | 1.44±0.05 | g/cm3 |

| WaterAbsorption(25℃.24Hrs) | ISO62 | 0.05% | |

| Meltingtemperature | ISO11357 | 343 | ℃ |

| DistortionTemperature | ISO75-1/-2 | 315 | ℃ |

| ContinuousserviceTemperature | UL74685 | 260 | ℃ |

| Thermalexpansioncoefficient | ASTMD696 | 2.4*10-6 | /K |

| TensileStrength(23℃) | ISO527 | 70 | MPa |

| Tensilemodulus(23℃) | ISO527 | 4.0 | GPa |

| TensileElongation(23℃) | ISO527 | 2.5% | |

| BendingStrength(23℃) | ISO178 | 100 | MPa |

| BendingModulus(23℃) | ISO178 | 4.0 | GPa |

| ImpactStrength(23℃) | ISO604 | 135 | MPa |

| LzodImpactStrength(Nonotched) | ISO180/U | 26 | |

| PoissonRatio | ISO527-2 | 0.35 | |

| RockwellHardness | GB3398.2 | 120 | |

| Flammability | UL94(1.5mm) | V-0 | |

| Dielectricstrength | IEC60243-1 | - | KV/mm |

| Dielectricconstant | IEC60250 | - | |

| ThermalConductivity | ISO22007 | 0.86 | W/(m·K) |

| SurfaceResistance | IEC90093 | 105 | Ω |

Certificate

About Us

Junhua was founded in 2007 and specializes in the development, production, and sale of high-performance engineering plastics, particularly PEEK, PI, PPSU, and other special polymers. The company has a modern factory occupying 15,000+ square meters , with 40+ extrusion lines ,Complete injection molding and CNC processing equipment, with an annual production capacity of over.

We have obtained multiple international certifications such as AS9100D (Aerospace), ISO9001, IATF1649 (Automotive), ISO13485 (Medical Devices), FDA, RoHS, REACH, SGS , and our products are fully traceable . Our customers cover multiple high-threshold industries in over 60 countries and regions , including aerospace, medical, semiconductor, electronics, food, and new energy vehicles. We are committed to becoming a global leader in PEEK solutions.

12 Patents for Invention

27 Utility Model Patents

15,000+㎡ Factory

40+ Extrusion Lines + Cleanroom

60+ Countries

30000+ Global Customers | 300 Million+ RMB Sales

500+ Team Members

18+ Years of Experience | 40+ Global Employees

Multiple International Certifications

AS9100D / ISO13485 / IATF16949 etc.

1000+ Global Partners

Serve 60+ Countries