PEEK Gear

PEEK Gear

Application of PEEK gears in power transmission systems

It's time to replace metal gears. PolyEtherEtherKetone (PEEK) Maintains wear resistance and

mechanical strength up to 480°F continuous use. PEEK is the performance material of choice

for aggressive environments such as high temperatures, wet processes, and heavy loads.

The main trends in the industry are: improving performance and efficiency, reducing weight

and achieving miniaturization while reducing costs, gear applications need to find new

materials to replace existing metal materials or perfect typical polymeric solutions to meet

future systems High demands on performance.

PEEK gears are widely used because of their light weight, wear resistance, self-lubrication,

low noise, corrosion resistance, high temperature resistance and other characteristics.

Junhua can provide customers with the determination and selection of gear raw

materials, surveying and drawing, gear design, mold opening and injection molding, sample

processing, and mass production, as well as application scenarios, working conditions and

PEEK gear solutions.

PEEK Gear

PEEK Gear

PEEK Gear

In all industries, there is an increasing demand for high-performance, high-precision gears

that are reliable even in demanding operating environments...So, PEEK is a reliable

choice.

Compared with metal gears, PEEK gears offer a number of performance advantages: 70% less

weight; 80% reduction in inertia; NVH(Noise,Vibration&Harshness) is reduced by 3 dB, that

means it's reduced by 50%; Chemical corrosion resistance, good reliability in harsh

environments.

- ◆ Long life

- ◆ Low energy consumption

- ◆ Light weight

- ◆ Low noise

PEEK Gear

PEEK Gear Processing Equipment

PEEK gears processed by machining and injection molding process are widely used because of

their many characteristics and advantages. In order to better meet the needs of customers

for PEEK gear products, our company has purchased several CNC gear hobbing machines. The

specific processing range is as follows:

At present, it can process spur gears and helical gears with a module between 0.5-5.08, a

diameter of 200mm and a height of 155mm. It can process PEEK spur gears, PEEK helical gears,

PEEK sprockets, PEEK worm gears, PEEK flowers Key gears, etc. and PEEK products with toothed

grooves on the circumference, when the processed gears are used to transport liquids, the

flow rate can be within plus or minus 0.025L/min.

PEEK Parts

PEEK Gear Application Case

The main trend in the industry today is to increase performance and efficiency, reduce weight and achieve miniaturization while reducing costs. In gear applications, engineers are looking for new materials to replace existing metallic materials, or to perfect typical polymeric solutions to meet the high performance demands of future systems. Because different types of loads are always sent at the same time, the gears need to meet multiple complex needs. The proper operation of gears depends on good friction and mechanical properties, performance against aggressive media, durability and heat resistance, and dimensional accuracy.

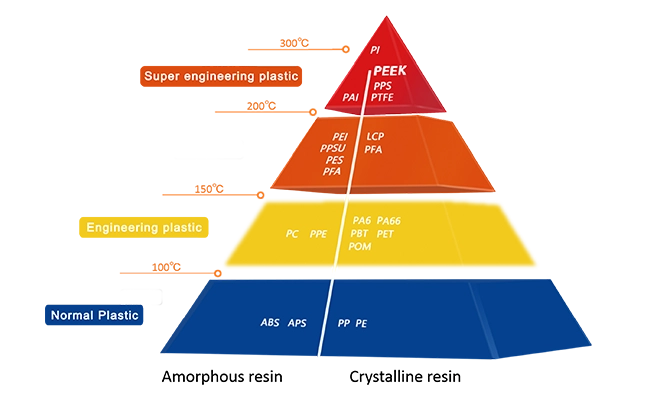

Polyetheretherketone (PEEK) is a new type of high-performance special engineering plastics, which has been produced and used for more than 30 years.

PEEK vs Traditional Materials

| Material | Display Image | Density | Core Features |

|---|---|---|---|

| PEEK 5600G (Pure PEEK) |

|

1.3 g/cm³ | Lightweighting · Excellent Processing Performance · High Toughness |

| PEEK 5600CF30 (Carbon Fiber Reinforced) |

|

1.4 g/cm³ | Excellent Wear Resistance · Suitable for High-Load Gears |

| PEEK 5600LF30 (Composite Lubricated) |

|

1.43 g/cm³ | Strong Self-Lubricating Capability · Low Coefficient of Friction |

| PEEK 5600GF30 (Glass Fiber Reinforced) |

|

1.5 g/cm³ | High Strength · High Rigidity · Excellent Heat Resistance |

| Steel |

|

7.85 g/cm³ | High Weight · Requires Lubrication · High Noise · High Corrosion Risk |

| Brass |

|

8.9 g/cm³ | High Weight · High Cost · Prone to Oxidation |

Custom Development

Customer Requirements

Gear Parameters

Customer Samples

Mapping and Drawing

Mold Design

Technical Communication

Mold Processing

Sample Production

Product Delivery

The current industry trend is to increase performance and efficiency, reduce weight, and achieve miniaturization while lowering costs. New materials are needed to replace metals to meet the high performance requirements of future systems. PEEK gears are widely used due to their advantages such as lightweighting, wear resistance, self-lubrication, low noise, corrosion resistance, and high-temperature resistance.

Jiangsu Junhua Co., Ltd. can provide customers with gear raw material determination and selection, mapping and drawing, gear design, mold opening and injection molding, sample processing, and mass production, along with application scenarios and PEEK gear solutions.

Products

PEEK gear (transmission control)

PEEK wear-resistant gear

PEEK wear-resistant duplex gear

PEEK gears for robots

PEEK gear

PEEK driven gear

What is PEEK?

PEEK and its modified composite materials show excellent performance under high temperature and high humidity conditions. PEEK have excellent chemical corrosion resistance, self-lubricating, and wear-resistant properties, so it has become the most ideal material to replace copper alloys and ordinary rubber. Compared with them, PEEK has longer service life which can reduce equipment operating costs, improve equipment operating reliability.

High Temperature Performance

PEEK's performance can remain stable in the temperature range from -196°C to 260°C. Under extreme working conditions, it can withstand 300"C for a short time. The performance of PEEK is still reliable even in high temperatures of several kilometers underground work environment.

High Strength and Wear Resistance

Compared with other plastics, PEEK is resistant to compression, impact and also have good fatigue resistance. PEEK is durable in mechanical equipment and wear-resistant environments.

Double the Service Life

PEEK sealing solutions can improve the part service life. Some domestic chemical companies use the PEEK5600FE20 polytetrafluoroethylene modified material designed by Junhua to replace the original material, the service life of the wear parts can even be extended by 1.3-3 times.

Corrosion Resistance

PEEK is chemically inert, and has no reaction to most acids, oils, greases and all other organic and inorganic solvents or enzymes, and can still maintain good strength and dimensional stability.

Self-lubricating

PEEK has low friction coefficient, low running resistance, can be used without oil in some working conditions. The equipment is cleaner, thus improving process reliability, improving energy efficiency and saving costs.

More dom in Design

Injection molds can be used for rapid injection molding of large quantities of complex special-shaped parts, and the cost is low compared to machining.

PEEK Material and Types of it's Modification

PEEK5600G (unfilled PEEK or natural PEEK)

PEEK5600G is one of unfilled or natural PEEK.Outstanding chemical resistance and a high operating temperature (up to 250℃/480F) round out PEEK profile.PEEK5600G has excellent dimensional stability combined with high creep stability, ensuring the suitability of PEEK for the most sophisticated machined parts.

PEEK5600GF30 ( 30% glass fiber filled PEEK)

Compared with unfilled PEEK(PEEK5600G),this 30% glass fiber reinforced PEEK material(PEEK5600GF30) exhibits increased mechanical strength and high rigidity.Plus, improved creep strength and dimensional stability are delivered by the 30% glass fiber filled PEEK.

PEEK5600CF30 (30% carbon fiber filled PEEK)

PEEK5600CF30 is a 30% carbon filled PEEK material that is manufactured by Junhua. Its carbon fiber reinforcement supports the material a high level of rigidity. Carbon fiber reinforced PEEK demonstrates very high mechanical strength values.

PEEK5600LF30( HPV PEEK or bearing grade PEEK)

PEEK5600LF30 black is developed especially for bearing and sliding applications. HPV PEEK is based on a PEEK polymer that has been modified with 10% each of PTFE, graphite and carbon fibres. It combines the properties of a high-grade matrix material with special, wear-improving additives.

Contact Us

Service

Junhua offers one-stop PEEK solutions from design to after-sales, ensuring quality, innovation, and customer satisfaction.

Design and processing

Junhua offers injection molding, machining, and extrusion solutions to optimize design and cost.

Material selection

Junhua specializes in PEEK with multiple grades and recommends the best engineering plastics for your needs.

Measurement

Junhua uses high-precision instruments to provide customers with accurate drawings.

Sampling

Junhua supplies samples for testing and refines designs until approval for mass production.

Mass Production

Junhua controls raw materials, processes, and inspections to ensure consistent product quality.

Quality Control

Junhua follows ISO9001 standards and provides full inspection reports as required.

Improve

Junhua continuously optimizes designs and processes through improvement systems and case experience.

After-sales Service

Junhua offers complete after-sales support to resolve technical issues and protect customer interests.

Advantages

Choosing Junhua means choosing a partner with a complete industrial chain, strong technology research and development capabilities, an efficient production system, strict quality assurance, and excellent customer support.

Industry Deep Dive

18 years of experience in high-performance engineering plastics, serving high-barrier industries such as aerospace and medical, trusted globally.

Complete Industry Chain

From aggregation to processing, a one-stop PEEK solution, simplifying purchases and reducing risks.

Technology Research and Development

12 items of invention patents, 27 items of utility model patents, with collaboration with universities, continuous innovation.

Production Capability

40+ high-efficiency extrusion lines, 500+ professional teams, quick response to global demands.

Quality Assurance

Strict quality control, product traceability from aggregation to processing, three-dimensional detection, COA quality report.

Customer Support

Material selection, mold design, custom processing, and complete after-sales support, becoming your strategic partner.

About Us

Junhua was founded in 2007 and specializes in the development, production, and sale of high-performance engineering plastics, particularly PEEK, PI, PPSU, and other special polymers. The company has a modern factory occupying 15,000+ square meters , with 40+ extrusion lines ,Complete injection molding and CNC processing equipment, with an annual production capacity of over.

We have obtained multiple international certifications such as AS9100D (Aerospace), ISO9001, IATF1649 (Automotive), ISO13485 (Medical Devices), FDA, RoHS, REACH, SGS , and our products are fully traceable . Our customers cover multiple high-threshold industries in over 60 countries and regions , including aerospace, medical, semiconductor, electronics, food, and new energy vehicles. We are committed to becoming a global leader in PEEK solutions.

12 Patents for Invention

27 Utility Model Patents

15,000+㎡ Factory

40+ Extrusion Lines + Cleanroom

60+ Countries

30000+ Global Customers | 300 Million+ RMB Sales

500+ Team Members

18+ Years of Experience | 40+ Global Employees

Multiple International Certifications

AS9100D / ISO13485 / IATF16949 etc.

1000+ Global Partners

Serve 60+ Countries