Advanced PEEK

Filament Solutions

Engineered for extreme performance. From medical implants to aerospace components, our PEEK and PEKK filaments define the future of additive manufacturing and industrial weaving.

Why Choose Our PEEK Materials?

Replacing metal with high-performance polymers reduces weight without compromising strength.

Thermal Resistance

Withstands continuous use up to 260°C and short-term exposure up to 300°C. Ideal for engine parts and sterilization.

Metal Replacement

80% lighter than stainless steel with excellent fatigue resistance and mechanical strength. Perfect for aerospace.

Biocompatible

Our implant-grade PEEK meets YYT0660-2008 standards with a modulus close to cortical bone. X-ray transparent.

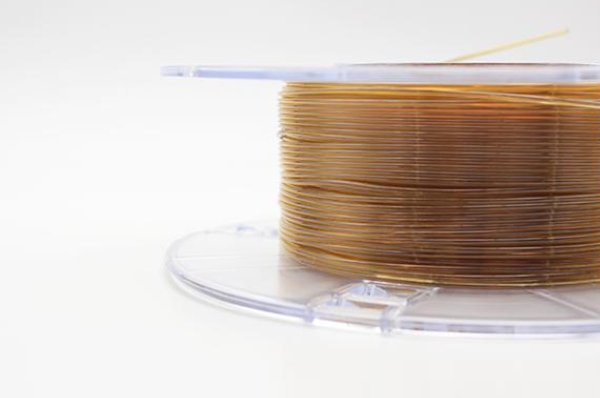

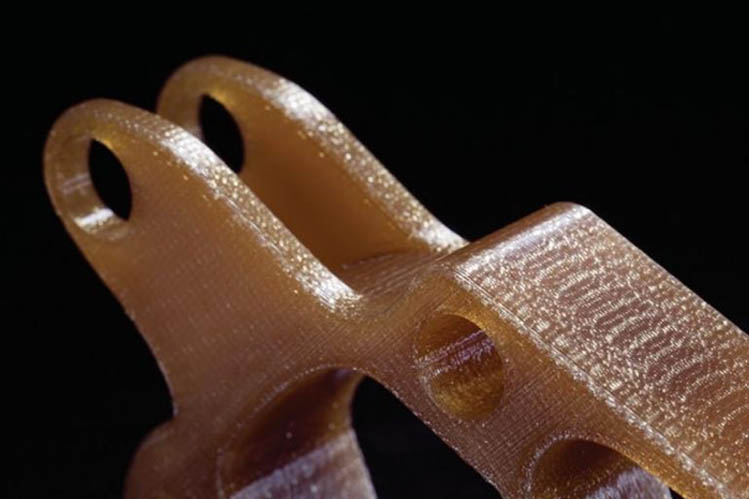

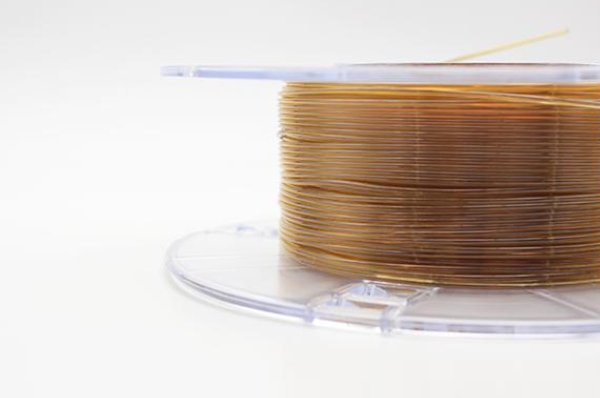

3D Printing PEEK Filament

Our high-toughness, high-strength PEEK filaments are produced via continuous extrusion, ensuring dimensional stability for kilometers of printing without breakage. Designed for medical and industrial applications where failure is not an option.

Key Applications

- ● Medical Implants: Customizable structures matching patient needs, X-ray transparent, and chemically stable.

- ● Aerospace & Auto: Lightweight components resistant to hydrolysis and flame.

- ● Oil & Gas: Excellent chemical resistance for complex parts.

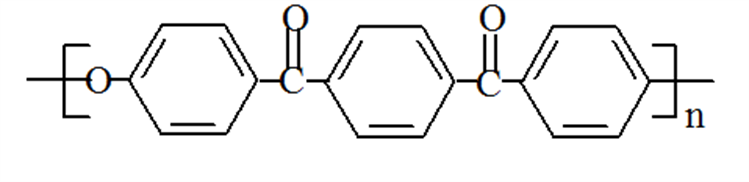

PEKK: Polyetherketoneketone

Higher thermal performance and rigidity than standard PEEK due to a unique E/K ratio.

Why upgrade to PEKK?

PEKK contains more rigid benzene rings and ketone groups (Ratio 2:1) compared to PEEK. This unique molecular structure results in higher melting points, better glass transition temperatures, and superior compressive strength.

Extreme Heat

Short-term exposure up to 300℃. Pure resin HDT 150-175℃.

Chemical Proof

Resistant to almost all organics/inorganics except specialized acids.

Flame Retardant

Inherently low smoke and low toxicity.

Aerospace Ready

Used in Boeing's Starliner space capsule.

PEKK Chemical Structure & Filament

Applications: Filter Cloth & Cable Insulation

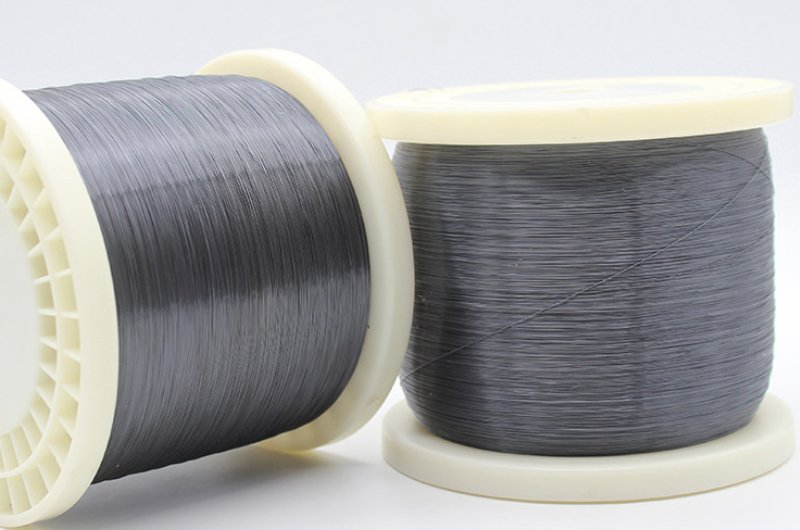

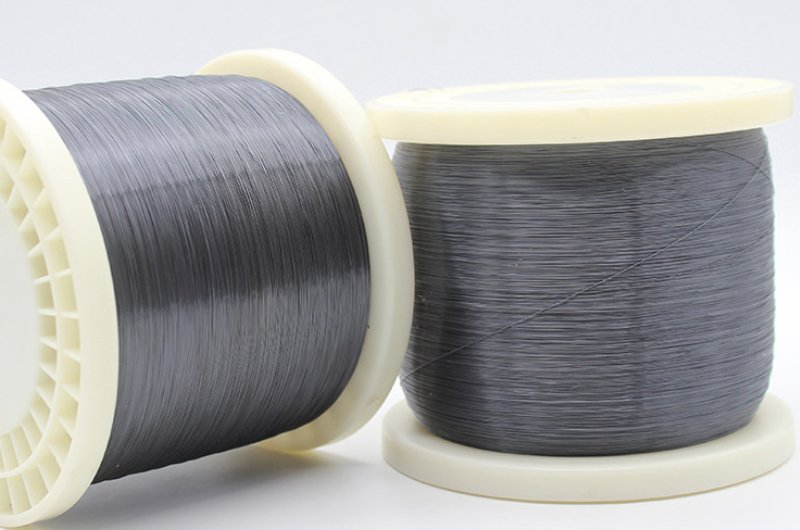

PEEK Monofilament (Fiber)

Extruded from PEEK 5602G specialized raw material, our monofilaments break traditional process limitations. They offer exceptional insulation, strength, and biocompatibility for weaving and filtration industries.

Target Applications

Specifications Snapshot

PEEK Filament

Polyether ether ketone, or PEEK, is one of the highest performing polymer plastics available.

This high-purity and high-temperature polymer has excellent dielectric properties, a very

low coefficient of friction, and withstands the most rigorous physical and mechanical

stresses.

Junhua manufactures PEEK tubing by extrusion,precision PEEK tubing are mainly used

in HPLC and medical industry, all PEEK tubing is extruded in Junhua's GMP standard clean

room. Junhua can ensure OD & ID ±0.03mm tolerance in our standard extruded tubing.

Colored PEEK tubing, color stripped PEEK tubing and special modified PEEK tubing is also

available.

Main Advantages of PEEK Filament

- ● Good wearing performance with or without load

- ● High service temperature(long term 260C

- ● Good mechanical strength

- ● Good chemical resistance & Hydrosis resistance

- ● FDA approved

Products

3D Printing PEEK Filament

PEKK polyetherketoneketone 3D printing filament

PEEK monofilament (fiber)

PEEK filaments

Contact Us

PEEK Typical Data

| Item | Standard | Data | Units |

| Color | - | Natural | |

| Density | ISO 1138 | 1.3±0.01 | g/cm3 |

| Water Absorption (25℃.24Hrs) | ISO 62 | 0.05 % | |

| Melting temperature | ISO 11357 | 343 | ℃ |

| Distortion Temperature | ISO 75-1/-2 | 163 | ℃ |

| Continuous service Temperature | UL 74685 | 260 | ℃ |

| Thermal expansion coefficient | ASTM D696 | 4.7*10-6 | /K |

| Tensile Strength (23℃) | ISO 527 | 100 | MPa |

| Tensile modulus (23℃) | ISO 527 | 3.8 | GPa |

| Tensile Elongation (23℃) | ISO 527 | 27 % | |

| Bending Strength (23℃) | ISO 178 | 163 | MPa |

| Bending Modulus (23℃) | ISO 178 | 3.5 | GPa |

| Impact Strength(23℃) | ISO 604 | 123 | MPa |

| Lzod Impact Strength (No notched) | ISO 180/U | No Break | kJ/m2 |

| Poisson Ratio | ISO 527-2 | 0.4 | |

| Rockwell Hardness | GB3398.2 | 118 | |

| Flammability | UL 94 (1.5 mm) | V-0 | |

| Dielectric strength | IEC 60243-1 | 18 | KV/mm |

| Dielectric constant | IEC 60250 | 3.2 | |

| Thermal Conductivity | ISO 22007 | 0.28 | W/(m·K) |

| Surface Resistance | IEC 90093 | 1015 | Ω |

| Item | Standard | Data | Units |

| Color | - | Black | |

| Density | ISO 1138 | 1.4±0.03 | g/cm3 |

| Water Absorption (25℃.24Hrs) | ISO 62 | 0.05 % | |

| Melting temperature | ISO 11357 | 343 | ℃ |

| Distortion Temperature | ISO 75-1/-2 | 315 | ℃ |

| Continuous service Temperature | UL 74685 | 260 | ℃ |

| Thermal expansion coefficient | ASTM D696 | 1.5*10-6 | /K |

| Tensile Strength (23℃) | ISO 527 | 125 | MPa |

| Tensile modulus (23℃) | ISO 527 | 9.3 | GPa |

| Tensile Elongation (23℃) | ISO 527 | 2.5 % | |

| Bending Strength (23℃) | ISO 178 | 271 | MPa |

| Bending Modulus (23℃) | ISO 178 | 9.1 | GPa |

| Impact Strength(23℃) | ISO 604 | 196 | MPa |

| Lzod Impact Strength (No notched) | ISO 180/U | 38 | kJ/m2 |

| Poisson Ratio | ISO 527-2 | 0.35 | |

| Rockwell Hardness | GB3398.2 | 123 | |

| Flammability | UL 94 (1.5 mm) | V-0 | |

| Dielectric strength | IEC 60243-1 | - | KV/mm |

| Dielectric constant | IEC 60250 | - | |

| Thermal Conductivity | ISO 22007 | 0.95 | W/(m·K) |

| Surface Resistance | IEC 90093 | 105 | Ω |

| Item | Standard | Data | Units |

| Color | - | Natural | |

| Density | ISO 1138 | 1.5±0.01 | g/cm3 |

| Water Absorption (25℃.24Hrs) | ISO 62 | 0.05 % | |

| Melting temperature | ISO 11357 | 343 | ℃ |

| Distortion Temperature | ISO 75-1/-2 | 315 | ℃ |

| Continuous service Temperature | UL 74685 | 260 | ℃ |

| Thermal expansion coefficient | ASTM D696 | 2.2*10-6 | /K |

| Tensile Strength (23℃) | ISO 527 | 110 | MPa |

| Tensile modulus (23℃) | ISO 527 | 7.9 | GPa |

| Tensile Elongation (23℃) | ISO 527 | 3.5 % | |

| Bending Strength (23℃) | ISO 178 | 214 | MPa |

| Bending Modulus (23℃) | ISO 178 | 7.5 | GPa |

| Impact Strength(23℃) | ISO 604 | 142 | MPa |

| Lzod Impact Strength (No notched) | ISO 180/U | 41 | kJ/m2 |

| Poisson Ratio | ISO 527-2 | 0.35 | |

| Rockwell Hardness | GB3398.2 | 122 | |

| Flammability | UL 94 (1.5 mm) | V-0 | |

| Dielectric strength | IEC 60243-1 | 17 | KV/mm |

| Dielectric constant | IEC 60250 | 3.4 | |

| Thermal Conductivity | ISO 22007 | 0.31 | W/(m·K) |

| Surface Resistance | IEC 90093 | 1015 | Ω |

| Item | Standard | Data | Units |

| Color | - | Black | |

| Density | ISO1138 | 1.44±0.05 | g/cm3 |

| WaterAbsorption(25℃.24Hrs) | ISO62 | 0.05% | |

| Meltingtemperature | ISO11357 | 343 | ℃ |

| DistortionTemperature | ISO75-1/-2 | 315 | ℃ |

| ContinuousserviceTemperature | UL74685 | 260 | ℃ |

| Thermalexpansioncoefficient | ASTMD696 | 2.4*10-6 | /K |

| TensileStrength(23℃) | ISO527 | 70 | MPa |

| Tensilemodulus(23℃) | ISO527 | 4.0 | GPa |

| TensileElongation(23℃) | ISO527 | 2.5% | |

| BendingStrength(23℃) | ISO178 | 100 | MPa |

| BendingModulus(23℃) | ISO178 | 4.0 | GPa |

| ImpactStrength(23℃) | ISO604 | 135 | MPa |

| LzodImpactStrength(Nonotched) | ISO180/U | 26 | |

| PoissonRatio | ISO527-2 | 0.35 | |

| RockwellHardness | GB3398.2 | 120 | |

| Flammability | UL94(1.5mm) | V-0 | |

| Dielectricstrength | IEC60243-1 | - | KV/mm |

| Dielectricconstant | IEC60250 | - | |

| ThermalConductivity | ISO22007 | 0.86 | W/(m·K) |

| SurfaceResistance | IEC90093 | 105 | Ω |

Advantages

Choosing Junhua means choosing a partner with a complete industrial chain, strong technology research and development capabilities, an efficient production system, strict quality assurance, and excellent customer support.

Industry Deep Dive

18 years of experience in high-performance engineering plastics, serving high-barrier industries such as aerospace and medical, trusted globally.

Complete Industry Chain

From aggregation to processing, a one-stop PEEK solution, simplifying purchases and reducing risks.

Technology Research and Development

12 items of invention patents, 27 items of utility model patents, with collaboration with universities, continuous innovation.

Production Capability

40+ high-efficiency extrusion lines, 500+ professional teams, quick response to global demands.

Quality Assurance

Strict quality control, product traceability from aggregation to processing, three-dimensional detection, COA quality report.

Customer Support

Material selection, mold design, custom processing, and complete after-sales support, becoming your strategic partner.

About Us

Junhua was founded in 2007 and specializes in the development, production, and sale of high-performance engineering plastics, particularly PEEK, PI, PPSU, and other special polymers. The company has a modern factory occupying 15,000+ square meters , with 40+ extrusion lines ,Complete injection molding and CNC processing equipment, with an annual production capacity of over.

We have obtained multiple international certifications such as AS9100D (Aerospace), ISO9001, IATF1649 (Automotive), ISO13485 (Medical Devices), FDA, RoHS, REACH, SGS , and our products are fully traceable . Our customers cover multiple high-threshold industries in over 60 countries and regions , including aerospace, medical, semiconductor, electronics, food, and new energy vehicles. We are committed to becoming a global leader in PEEK solutions.

12 Patents for Invention

27 Utility Model Patents

15,000+㎡ Factory

40+ Extrusion Lines + Cleanroom

60+ Countries

30000+ Global Customers | 300 Million+ RMB Sales

500+ Team Members

18+ Years of Experience | 40+ Global Employees

Multiple International Certifications

AS9100D / ISO13485 / IATF16949 etc.

1000+ Global Partners

Serve 60+ Countries