PEEK Continuous Extruded Capillary Tubes

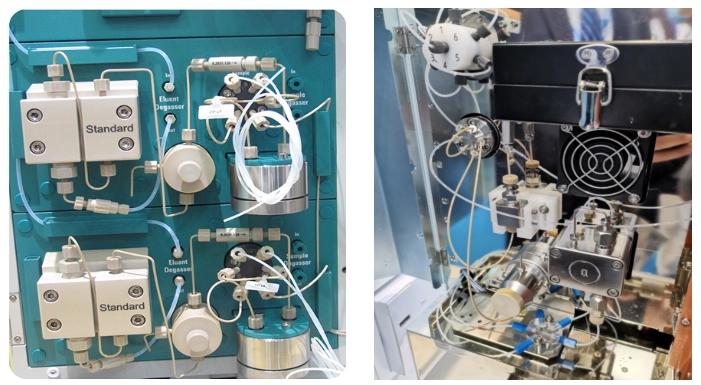

PEEK is widely used in the analytical instrument, semiconductor, and medical industries due to its excellent chemical stability and corrosion resistance. High-toughness, high-strength PEEK capillary tubes are formed through a continuous extrusion process, resulting in good dimensional stability and high-pressure resistance. They are used in fluid paths in various analytical instruments and for medical interventional and minimally invasive surgical instruments, such as:

We can perform secondary processing and forming on the tubes.

Professional Customization of PEEK medical catheters, capillary tubes, multi-lumen tubes, etc., with various mechanical properties to meet diverse customer customization needs.

Advanced Annular Printing Equipment and specialized printing technicians can achieve various ring and dot printing requirements. The color band is flat, the writing is clear, and the medical-grade ink will not peel off.

Independently Designed PEEK Capillary Flaring Tools can be custom-made according to customer requirements.

Medical-grade Dedicated Punching Equipment with high-precision drive control and automatic chip removal.

Customized Molds for high-temperature hot melting of PEEK capillary tubes, ensuring precise dimensions.

PEEK capillary tubes, after high-temperature shaping and cooling, do not rebound at the bend, and the bending area is smooth without wrinkles, meeting high customer standards.

Focusing on PEEK materials and application solutions, continuous innovation, and high-quality manufacturing.

Possessing over 18 years of experience in PEEK application R&D and production, providing full-process solutions from material to finished products.

Equipped with a large clean workshop for e-cigarette production, meeting high-standard production environment requirements.

Professional cutting equipment ensures processing accuracy and dimensional consistency.

The domestic PEEK full industrial chain company, providing integrated services for raw materials, molding, processing, and testing.

Professional secondary expansion equipment ensures stable shrinkage ratio and forming performance of the product.

Equipped with professional testing equipment, strictly controlling the product processing procedure and final quality.

Medical-Grade PEEK Capillary

Our high pressure tubing includes bioinert PEEK, formally known as poly ether ether ketone.

PEEK is a high-performance engineered polymer with mechanical and chemical resistance

properties that absorb high temperatures, making it highly resistant to thermal degradation.

PEEK tubing has one of the highest strength-to-weight ratios of any thermoplastic and the

strength required to withstand continuous use at HPLC pressure. Its distinct materials make

it inert to most solvents and give it a smooth internal surface that improves the resolution

of sample bands.

With its introduction into the marketplace, PEEK materials have become a popular replacement

for stainless steel tubing for fluidic needs.

PEEK acts as an excellent alternative for stainless steel tubing in high pressure applications and analytical systems. Its mechanical properties allow it to be used in many situations where stainless steel would become too reactive. Unlike stainless steel, PEEK tubing is flexible and can be easily cut into preferred lengths with a razor blade. PEEKs internal surface is much smoother than that of metal tubing, thereby reducing the risk of dilution and remixing of samples.

PEEK Advantages

PEEK Capillary Tube Specifications

| Number | Outer Diameter × Inner Diameter (mm) |

|---|---|

| 1 | 0.5×0.3~0.4 |

| 2 | 0.6×0.3~0.5 |

| 3 | 0.7×0.3~0.6 |

| 4 | 0.8×0.3~0.7 |

| 5 | 1/32"×0.25/0.5 |

| 6 | 0.9×0.3~0.8 |

| 7 | 1.0×0.3~0.9 |

| 8 | 1.1×0.3~1.0 |

| 9 | 1.2×0.3~1.1 |

| 10 | 1.3×0.3~1.2 |

| 11 | 1.4×0.3~1.3 |

| 12 | 1.5×0.3~1.4 |

| 13 | 1/16"×0.1/0.13/0.25/0.38/0.5/0.75/1.0/1.2 |

| 14 | 1.6×0.3~1.5 |

| 15 | 1.7×0.3~1.6 |

| 16 | 1.8×0.3~1.7 |

| 17 | 1.9×0.3~1.8 |

| 18 | 2.0×0.3~1.9 |

| 19 | 2.1×0.3~2.0 |

| 20 | 2.2×0.3~2.1 |

| 21 | 2.3×0.3~2.2 |

| 22 | 2.4×0.3~2.3 |

| 23 | 2.5×0.3~2.4 |

| 24 | 2.6×0.3~2.5 |

| 25 | 2.7×0.3~2.6 |

| 26 | 2.8×0.3~2.7 |

| 27 | 2.9×0.3~2.8 |

| 28 | 3.0×0.3~2.9 |

| 29 | 1/8"×1/16"/0.5/0.75/1.0/1.2/2.0/2.2 |

| 30 | 3.2×0.3~3.0 |

| 31 | 4.95×4.15/4.25/4.35/4.55 |

| 32 | 9.52×8.92 |

| 33 | 9.86×9.26 |

| 34 | 10×8.7 |

| 35 | 12×10/11 |

| 36 | 13×12 |

| 37 | 17.1×16.1 |

| 38 | 22.6×22.1 |

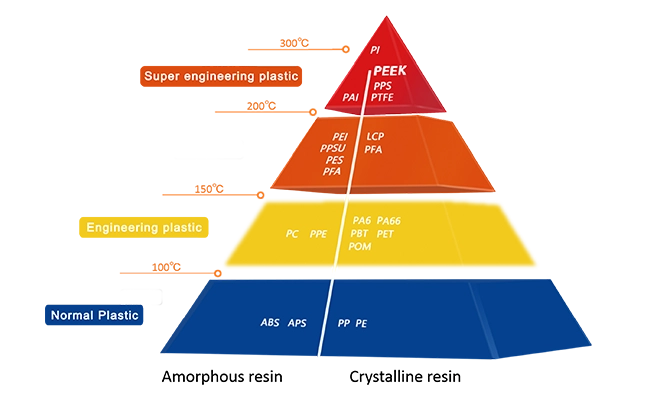

PEEK and its modified composite materials show excellent performance under high temperature and high humidity conditions. PEEK have excellent chemical corrosion resistance, self-lubricating, and wear-resistant properties, so it has become the most ideal material to replace copper alloys and ordinary rubber. Compared with them, PEEK has longer service life which can reduce equipment operating costs, improve equipment operating reliability.

PEEK's performance can remain stable in the temperature range from -196°C to 260°C. Under extreme working conditions, it can withstand 300"C for a short time. The performance of PEEK is still reliable even in high temperatures of several kilometers underground work environment.

Compared with other plastics, PEEK is resistant to compression, impact and also have good fatigue resistance. PEEK is durable in mechanical equipment and wear-resistant environments.

PEEK sealing solutions can improve the part service life. Some domestic chemical companies use the PEEK5600FE20 polytetrafluoroethylene modified material designed by Junhua to replace the original material, the service life of the wear parts can even be extended by 1.3-3 times.

PEEK is chemically inert, and has no reaction to most acids, oils, greases and all other organic and inorganic solvents or enzymes, and can still maintain good strength and dimensional stability.

PEEK has low friction coefficient, low running resistance, can be used without oil in some working conditions. The equipment is cleaner, thus improving process reliability, improving energy efficiency and saving costs.

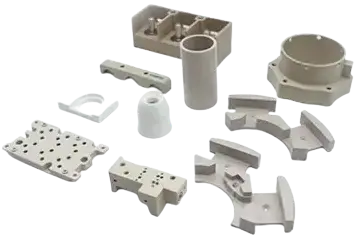

Injection molds can be used for rapid injection molding of large quantities of complex special-shaped parts, and the cost is low compared to machining.

| Item | Standard | Data | Units |

| Color | - | Natural | |

| Density | ISO 1138 | 1.3±0.01 | g/cm3 |

| Water Absorption (25℃.24Hrs) | ISO 62 | 0.05 % | |

| Melting temperature | ISO 11357 | 343 | ℃ |

| Distortion Temperature | ISO 75-1/-2 | 163 | ℃ |

| Continuous service Temperature | UL 74685 | 260 | ℃ |

| Thermal expansion coefficient | ASTM D696 | 4.7*10-6 | /K |

| Tensile Strength (23℃) | ISO 527 | 100 | MPa |

| Tensile modulus (23℃) | ISO 527 | 3.8 | GPa |

| Tensile Elongation (23℃) | ISO 527 | 27 % | |

| Bending Strength (23℃) | ISO 178 | 163 | MPa |

| Bending Modulus (23℃) | ISO 178 | 3.5 | GPa |

| Impact Strength(23℃) | ISO 604 | 123 | MPa |

| Lzod Impact Strength (No notched) | ISO 180/U | No Break | kJ/m2 |

| Poisson Ratio | ISO 527-2 | 0.4 | |

| Rockwell Hardness | GB3398.2 | 118 | |

| Flammability | UL 94 (1.5 mm) | V-0 | |

| Dielectric strength | IEC 60243-1 | 18 | KV/mm |

| Dielectric constant | IEC 60250 | 3.2 | |

| Thermal Conductivity | ISO 22007 | 0.28 | W/(m·K) |

| Surface Resistance | IEC 90093 | 1015 | Ω |

| Item | Standard | Data | Units |

| Color | - | Black | |

| Density | ISO 1138 | 1.4±0.03 | g/cm3 |

| Water Absorption (25℃.24Hrs) | ISO 62 | 0.05 % | |

| Melting temperature | ISO 11357 | 343 | ℃ |

| Distortion Temperature | ISO 75-1/-2 | 315 | ℃ |

| Continuous service Temperature | UL 74685 | 260 | ℃ |

| Thermal expansion coefficient | ASTM D696 | 1.5*10-6 | /K |

| Tensile Strength (23℃) | ISO 527 | 125 | MPa |

| Tensile modulus (23℃) | ISO 527 | 9.3 | GPa |

| Tensile Elongation (23℃) | ISO 527 | 2.5 % | |

| Bending Strength (23℃) | ISO 178 | 271 | MPa |

| Bending Modulus (23℃) | ISO 178 | 9.1 | GPa |

| Impact Strength(23℃) | ISO 604 | 196 | MPa |

| Lzod Impact Strength (No notched) | ISO 180/U | 38 | kJ/m2 |

| Poisson Ratio | ISO 527-2 | 0.35 | |

| Rockwell Hardness | GB3398.2 | 123 | |

| Flammability | UL 94 (1.5 mm) | V-0 | |

| Dielectric strength | IEC 60243-1 | - | KV/mm |

| Dielectric constant | IEC 60250 | - | |

| Thermal Conductivity | ISO 22007 | 0.95 | W/(m·K) |

| Surface Resistance | IEC 90093 | 105 | Ω |

| Item | Standard | Data | Units |

| Color | - | Natural | |

| Density | ISO 1138 | 1.5±0.01 | g/cm3 |

| Water Absorption (25℃.24Hrs) | ISO 62 | 0.05 % | |

| Melting temperature | ISO 11357 | 343 | ℃ |

| Distortion Temperature | ISO 75-1/-2 | 315 | ℃ |

| Continuous service Temperature | UL 74685 | 260 | ℃ |

| Thermal expansion coefficient | ASTM D696 | 2.2*10-6 | /K |

| Tensile Strength (23℃) | ISO 527 | 110 | MPa |

| Tensile modulus (23℃) | ISO 527 | 7.9 | GPa |

| Tensile Elongation (23℃) | ISO 527 | 3.5 % | |

| Bending Strength (23℃) | ISO 178 | 214 | MPa |

| Bending Modulus (23℃) | ISO 178 | 7.5 | GPa |

| Impact Strength(23℃) | ISO 604 | 142 | MPa |

| Lzod Impact Strength (No notched) | ISO 180/U | 41 | kJ/m2 |

| Poisson Ratio | ISO 527-2 | 0.35 | |

| Rockwell Hardness | GB3398.2 | 122 | |

| Flammability | UL 94 (1.5 mm) | V-0 | |

| Dielectric strength | IEC 60243-1 | 17 | KV/mm |

| Dielectric constant | IEC 60250 | 3.4 | |

| Thermal Conductivity | ISO 22007 | 0.31 | W/(m·K) |

| Surface Resistance | IEC 90093 | 1015 | Ω |

| Item | Standard | Data | Units |

| Color | - | Black | |

| Density | ISO1138 | 1.44±0.05 | g/cm3 |

| WaterAbsorption(25℃.24Hrs) | ISO62 | 0.05% | |

| Meltingtemperature | ISO11357 | 343 | ℃ |

| DistortionTemperature | ISO75-1/-2 | 315 | ℃ |

| ContinuousserviceTemperature | UL74685 | 260 | ℃ |

| Thermalexpansioncoefficient | ASTMD696 | 2.4*10-6 | /K |

| TensileStrength(23℃) | ISO527 | 70 | MPa |

| Tensilemodulus(23℃) | ISO527 | 4.0 | GPa |

| TensileElongation(23℃) | ISO527 | 2.5% | |

| BendingStrength(23℃) | ISO178 | 100 | MPa |

| BendingModulus(23℃) | ISO178 | 4.0 | GPa |

| ImpactStrength(23℃) | ISO604 | 135 | MPa |

| LzodImpactStrength(Nonotched) | ISO180/U | 26 | |

| PoissonRatio | ISO527-2 | 0.35 | |

| RockwellHardness | GB3398.2 | 120 | |

| Flammability | UL94(1.5mm) | V-0 | |

| Dielectricstrength | IEC60243-1 | - | KV/mm |

| Dielectricconstant | IEC60250 | - | |

| ThermalConductivity | ISO22007 | 0.86 | W/(m·K) |

| SurfaceResistance | IEC90093 | 105 | Ω |

Choosing Junhua means choosing a partner with a complete industrial chain, strong technology research and development capabilities, an efficient production system, strict quality assurance, and excellent customer support.

18 years of experience in high-performance engineering plastics, serving high-barrier industries such as aerospace and medical, trusted globally.

From aggregation to processing, a one-stop PEEK solution, simplifying purchases and reducing risks.

12 items of invention patents, 27 items of utility model patents, with collaboration with universities, continuous innovation.

40+ high-efficiency extrusion lines, 500+ professional teams, quick response to global demands.

Strict quality control, product traceability from aggregation to processing, three-dimensional detection, COA quality report.

Material selection, mold design, custom processing, and complete after-sales support, becoming your strategic partner.

Junhua was founded in 2007 and specializes in the development, production, and sale of high-performance engineering plastics, particularly PEEK, PI, PPSU, and other special polymers. The company has a modern factory occupying 15,000+ square meters , with 40+ extrusion lines ,Complete injection molding and CNC processing equipment, with an annual production capacity of over.

We have obtained multiple international certifications such as AS9100D (Aerospace), ISO9001, IATF1649 (Automotive), ISO13485 (Medical Devices), FDA, RoHS, REACH, SGS , and our products are fully traceable . Our customers cover multiple high-threshold industries in over 60 countries and regions , including aerospace, medical, semiconductor, electronics, food, and new energy vehicles. We are committed to becoming a global leader in PEEK solutions.

27 Utility Model Patents

40+ Extrusion Lines + Cleanroom

30000+ Global Customers | 300 Million+ RMB Sales

18+ Years of Experience | 40+ Global Employees

AS9100D / ISO13485 / IATF16949 etc.

Serve 60+ Countries

Contact Us Now and Enjoy a One-Stop Solution!Fill the Form to Get a Quote, Product Manual, Performance Parameters, Custom Solutions, Technical Consultation, and Samples