PEEK for Set Oil & Gas

PEEK Material Enhances The Performance Of Petroleum Equipment

PEEK Material Enhances The Performance Of Petroleum Equipment

PEEK polymer petroleum & petrochemical industry solutions can improve the production safety and stability of equipment in high temperature and corrosive environments to improve production efficiency.

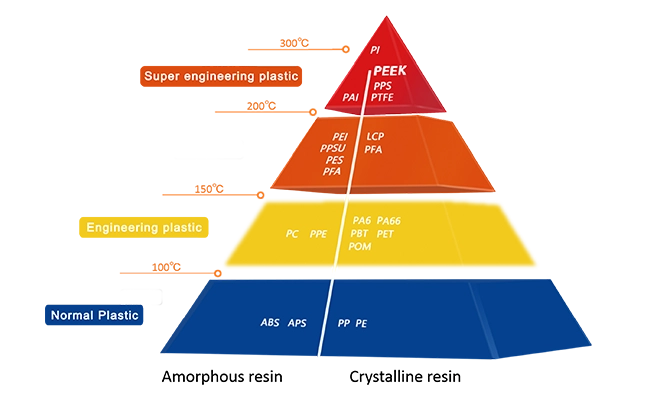

What is PEEK?

PEEK and its modified composite materials show excellent performance under high temperature and high humidity conditions. PEEK have excellent chemical corrosion resistance, self-lubricating, and wear-resistant properties, so it has become the most ideal material to replace copper alloys and ordinary rubber. Compared with them, PEEK has longer service life which can reduce equipment operating costs, improve equipment operating reliability.

High Temperature Performance

PEEK's performance can remain stable in the temperature range from -196°C to 260°C. Under extreme working conditions, it can withstand 300"C for a short time. The performance of PEEK is still reliable even in high temperatures of several kilometers underground work environment.

High Strength and Wear Resistance

Compared with other plastics, PEEK is resistant to compression, impact and also have good fatigue resistance. PEEK is durable in mechanical equipment and wear-resistant environments.

Double the Service Life

PEEK sealing solutions can improve the part service life. Some domestic chemical companies use the PEEK5600FE20 polytetrafluoroethylene modified material designed by Junhua to replace the original material, the service life of the wear parts can even be extended by 1.3-3 times.

Corrosion Resistance

PEEK is chemically inert, and has no reaction to most acids, oils, greases and all other organic and inorganic solvents or enzymes, and can still maintain good strength and dimensional stability.

Self-lubricating

PEEK has low friction coefficient, low running resistance, can be used without oil in some working conditions. The equipment is cleaner, thus improving process reliability, improving energy efficiency and saving costs.

More dom in Design

Injection molds can be used for rapid injection molding of large quantities of complex special-shaped parts, and the cost is low compared to machining.

PEEK Material and Types of it's Modification

PEEK5600G (unfilled PEEK or natural PEEK)

PEEK5600G is one of unfilled or natural PEEK.Outstanding chemical resistance and a high operating temperature (up to 250℃/480F) round out PEEK profile.PEEK5600G has excellent dimensional stability combined with high creep stability, ensuring the suitability of PEEK for the most sophisticated machined parts.

PEEK5600GF30 ( 30% glass fiber filled PEEK)

Compared with unfilled PEEK(PEEK5600G),this 30% glass fiber reinforced PEEK material(PEEK5600GF30) exhibits increased mechanical strength and high rigidity.Plus, improved creep strength and dimensional stability are delivered by the 30% glass fiber filled PEEK.

PEEK5600CF30 (30% carbon fiber filled PEEK)

PEEK5600CF30 is a 30% carbon filled PEEK material that is manufactured by Junhua. Its carbon fiber reinforcement supports the material a high level of rigidity. Carbon fiber reinforced PEEK demonstrates very high mechanical strength values.

PEEK5600LF30( HPV PEEK or bearing grade PEEK)

PEEK5600LF30 black is developed especially for bearing and sliding applications. HPV PEEK is based on a PEEK polymer that has been modified with 10% each of PTFE, graphite and carbon fibres. It combines the properties of a high-grade matrix material with special, wear-improving additives.

Products

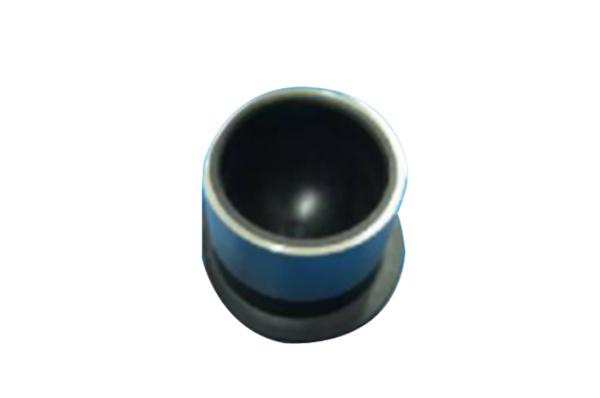

PEEK bushing (JUNHUA-HT4600CF30)

PEEK Filter Cloth

Thrust bearing PEEK wear block

PEEK isolation sleeve for magnetic pump

PEEK distribution plate

PEEK plunger boots

Contact Us

Typical Application in Oil & Gas Industry

Typical Application in Oil & Gas Industry

PEEK Seals

Effective sealing often means safe, long-lasting, efficient production operations, which means less downtime and lower costs. PEEK retaining rings are favored in the energy industry for their outstanding reliability. PEEK sealing solutions are proven and reliable, extending device life and improving recovery rates in high temperature and high pressure corrosive environments.

In the environment of seawater, hydrocarbons, and 100% hydrogen sulfide gas, the strength retention rate reaches 100% after a high temperature of 175 ° C for 1000 hours.

Double of the compression resistance of PTFE, increase the creep resistance by 300 times, and increase the compressive creep resistance of PTFE by 18 times.

Replace the metal spring to reduce the risk caused by the wear of the seal and the contact with the well wall (energy absorbing spring).

Compressor Parts

With demanding of industry requirements for longer component life and less downtime, PEEK solutions provide compressor parts with a unique combination of performance. Reduced maintenance costs and material weight, excellent integrity, immunity to aggressive chemicals and fluids, and durability in mechanical equipment and wear-prone environments.

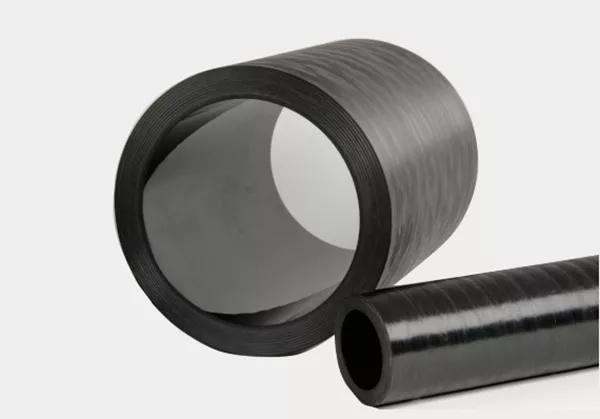

Continuous Carbon Fiber CF/PEEK Composite Pipe

PEEK is increasingly used in many oil and gas industry applications due to its unique combination of chemical resistance, electrical properties, abrasion resistance, hydrolysis resistance and high temperature resistance. Production As the operating systems of oil and gas reservoirs continue to expand, new deep-sea platforms require new solutions to deliver reliable performance in environments with higher temperatures, higher pressures and extreme depths. Reliability is a top priority because of the huge investment, intervention costs and yield losses, which place higher demands on the material.

Application in ESP Electric Submersible Pump

ESP technology is rapidly gaining popularity and is used in nearly every operating area in the world. PEEK insulating ring can withstand the high temperature generated by the coil heating caused by the ESP submersible motor long time work, and it provides a good insulating effect while ensuring sufficient mechanical strength. Excellent high temperature resistance, excellent insulation, insulation and mechanical strength even at 250°C.

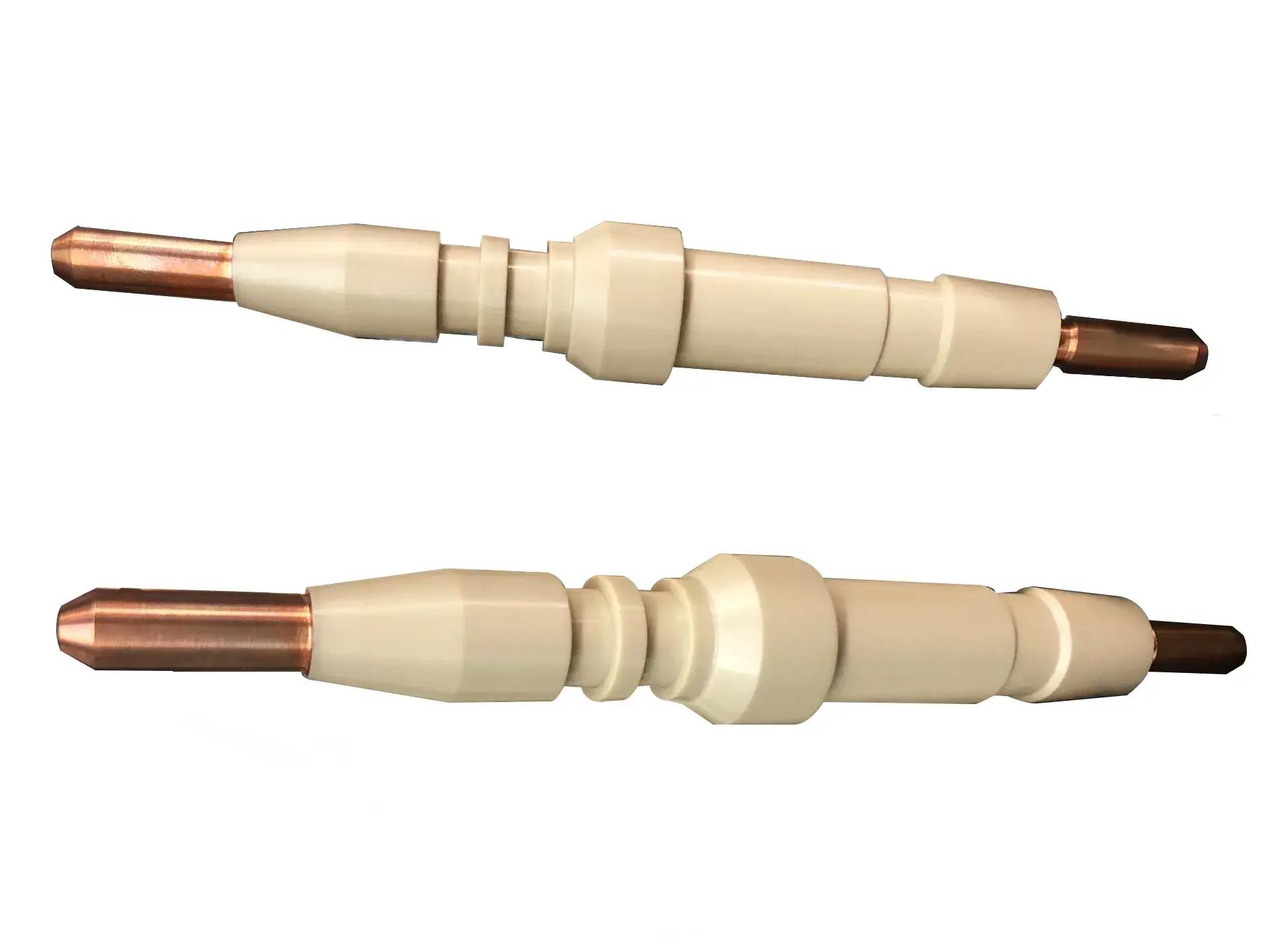

PEEK Well Logging Part

PEEK provide the chemical and insulating properties needed to protect signals at high temperatures, providing the ability to create seamless connectors that fully insulate conductive pins, ensuring their performance in the harshest conditions. The high purity and strength of PEEK allow the design of thinner thin-walled cross-sections in more compact connectors, enabling excellent performance even in tight spaces. Resistant to typical oil and gas industry fluids.

Common PEEK Grades and Properties

1. PEEK5600G (brown-gray/khaki) is made from pure polyetheretherketone resin and offers the best toughness and impact resistance of all PEEK grades. Pure PEEK can be sterilized using convenient methods (steam, dry heat, ethanol, and gamma-rays), and the raw materials used in its manufacture comply with EU and US FDA food compatibility regulations. These characteristics make it widely used in the medical, pharmaceutical, and food processing industries.

2. PEEK5600LF30 (black) The addition of PTFE, graphite, and carbon fiber makes PEEK5600LF30 a bearing-grade plastic. Its superior tribological properties (low coefficient of friction, wear resistance, and high peak pressure limit) make it an ideal material for this class of friction applications.

3. PEEK5600GF30 (Brown-Gray): This material is a reinforced grade of plastic filled with 30% glass fiber. It offers superior rigidity, creep resistance, and dimensional stability compared to PEEK, making it ideal for structural parts. It can withstand fixed loads for extended periods at high temperatures. If PEEK5600GF30 is used as a sliding component, its suitability should be carefully verified, as the glass fiber can scratch mating surfaces.

4. PEEK5600CF30 (Black): This material is reinforced with 30% carbon fiber. It offers superior mechanical properties (higher elastic modulus, mechanical strength, and creep resistance) and wear resistance compared to PEEK5600GF30. Furthermore, carbon fiber-reinforced plastic has 3.5 times the thermal conductivity of unreinforced PEEK, dissipating heat more quickly from the bearing surface.

Mechanical Properties

| Item | Test Standard or Instrument |

Unit | PEEK5600G 100% PEEK |

PEEK5600GF30 PEEK+30% glass fiber |

PEEK5600CF30 PEEK+30% carbon fiber |

PEEK5600LF30 PEEK+30% (carbon fiber +graphite+PTFE) |

PEEK5600FE20 PEEK+20%PTFE |

|---|---|---|---|---|---|---|---|

| Tensile Strength (23℃) | ISO 527 | MPa | 95 | 175 | 250 | 145 | 70 |

| Tensile Modulus (23℃) | ISO 527 | GPa | 3.8 | 11 | 23 | 12.5 | / |

| Elongation at Break (23℃) | ISO 527 | % | 35 | 2.0 | 1.5 | 2.2 | / |

| Flexural Strength (23℃) | ISO 178 | MPa | 155 | 235 | 350 | 220 | 118 |

| Flexural Modulus (23℃) | ISO 178 | GPa | 3.5 | 10 | 21 | 11 | / |

| Charpy Impact Strength (unnotched) | ISO 179/1U | kJ/m2 | No break | 55 | 45 | 32 | No break |

| Cantilever Beam Impact Strength (notched) | ISO 180/A | kJ/m2 | 4 | 6 | 6.5 | 4 | 6 |

Thermal Properties

| Item | Test Standard or Instrument |

Unit | PEEK5600G 100% PEEK |

PEEK5600GF30 PEEK+30% glass fiber |

PEEK5600CF30 PEEK+30% carbon fiber |

PEEK5600LF30 PEEK+30% (carbon fiber +graphite+PTFE) |

PEEK5600FE20 PEEK+20%PTFE |

|---|---|---|---|---|---|---|---|

| Melting Point | ISO11357 | ℃ | 343 | 343 | 343 | 343 | 343 |

| Glass Transition Temperature | ISO11357 | ℃ | 143 | 143 | 143 | 143 | 150 |

| Heat Deflection Temperature | ISO 75A/B | 1.8MPa. ℃ | 152 | 315 | 315 | 293 | 150 |

| Thermal Expansion Coefficient | ASTM D696 | ppm K-1 | 45 | 22 | 15 | 22 | 70 |

| Thermal Conductivity | ISO /CD22007-4 | W/(m·K) | 0.29 | 0.32 | 0.95 | 0.86 | / |

Electrical Properties

| Item | Test Standard or Instrument |

Unit | PEEK5600G 100% PEEK |

PEEK5600GF30 PEEK+30% glass fiber |

PEEK5600CF30 PEEK+30% carbon fiber |

PEEK5600LF30 PEEK+30% (carbon fiber +graphite+PTFE) |

PEEK5600FE20 PEEK+20%PTFE |

|---|---|---|---|---|---|---|---|

| Dielectric Strength (2mm) | IEC 60243-1 | kV/mm | 20 | 19 | / | / | 19 |

| Dielectric Constant | IEC 62631 | - | 3.0 | 3.3 | / | / | 2.7 |

| Surface Resistivity | GB/T31838.3 | Ω | 1015 | 1014 | / | / | 1015 |

| Volume Resistivity | IEC 62631 | Ω·cm | 1015 | 1015 | 105 | 106 | / |

Other Properties

| Item | Test Standard or Instrument |

Unit | PEEK5600G 100% PEEK |

PEEK5600GF30 PEEK+30% glass fiber |

PEEK5600CF30 PEEK+30% carbon fiber |

PEEK5600LF30 PEEK+carbon fiber +graphite+PTFE |

PEEK5600FE20 PEEK+20%PTFE |

|---|---|---|---|---|---|---|---|

| Color | / | / | Natural | Natural | Black | Black | Natural |

| Melt Flow Index (400℃, 2.16kg) | ISO 1133 | g/10min | 6-10 | 2-5 | 1-3 | 2-5 | / |

| Density | ISO 1183 | g/cm3 | 1.30±0.02 | 1.50±0.02 | 1.40±0.02 | 1.44±0.02 | 1.41±0.02 |

| Water Absorption (23℃, 24Hrs) | ISO 62-1 | % | 0.07 | 0.05 | 0.04 | 0.05 | 0.15 |

| Rockwell Hardness | / | HRR | 118 | 119 | 121 | 108 | 113 |

| Flammability Rating | UL 94 | / | V-0 | V-0 | V-0 | V-0 | / |

| Coefficient of Friction | ASTM D3702 | 100N-120rpm | 0.30-0.38 | 0.38-0.46 | 0.15-0.25 | 0.18-0.30 | 0.1-0.2 |

*This data is for reference and not a guarantee. For a more detailed data sheet, please contact our company's technical department.