Corona Resistance / High PDIV

Excellent dielectric strength and partial discharge inception voltage, suitable for 800V+ platform electric drive systems.

JUNHUA® PEEK offers high-reliability insulation and sealing solutions for electric drive, battery, and hydrogen fuel cell applications, meeting demanding requirements such as high voltage, high temperature, chemical resistance, and low permeation.

Excellent dielectric strength and partial discharge inception voltage, suitable for 800V+ platform electric drive systems.

Facilitates co-extrusion with copper conductors and metal frames, ensuring stable interfaces.

Resists hydrogen media, coolants, insulating oils, and various corrosive media.

Continuous use temperature up to ~260°C, maintains toughness and strength down to -100°C.

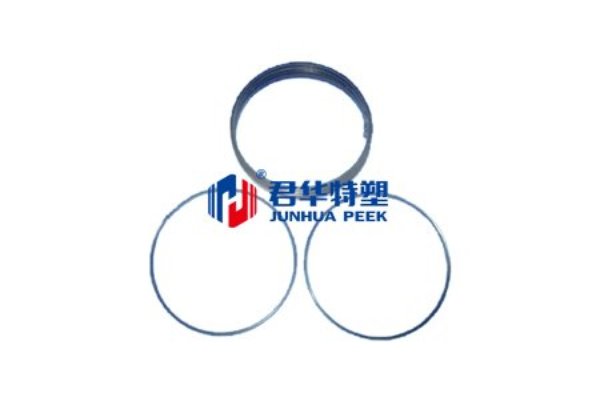

Maintains dimensional and structural stability under harsh conditions over long periods.

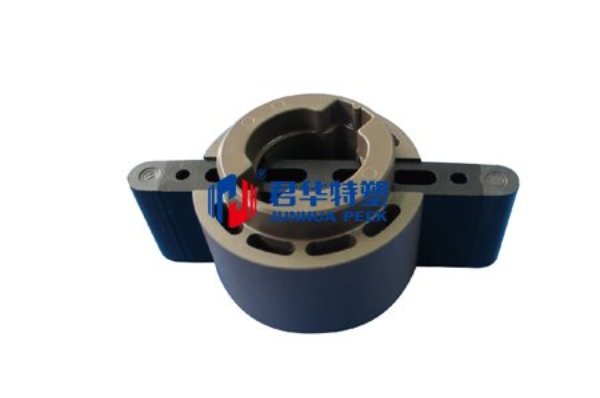

Creep-resistant, compression-resistant, bend-resistant without cracking, suitable for dynamic sealing support components.

Junhua offers one-stop PEEK solutions from design to after-sales, ensuring quality, innovation, and customer satisfaction.

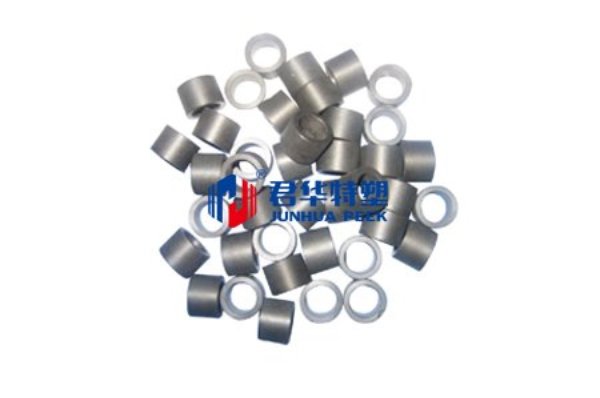

Junhua offers injection molding, machining, and extrusion solutions to optimize design and cost.

Junhua specializes in PEEK with multiple grades and recommends the best engineering plastics for your needs.

Junhua uses high-precision instruments to provide customers with accurate drawings.

Junhua supplies samples for testing and refines designs until approval for mass production.

Junhua controls raw materials, processes, and inspections to ensure consistent product quality.

Junhua follows ISO9001 standards and provides full inspection reports as required.

Junhua continuously optimizes designs and processes through improvement systems and case experience.

Junhua offers complete after-sales support to resolve technical issues and protect customer interests.

Junhua was founded in 2007 and specializes in the development, production, and sale of high-performance engineering plastics, particularly PEEK, PI, PPSU, and other special polymers. The company has a modern factory occupying 15,000+ square meters , with 40+ extrusion lines ,Complete injection molding and CNC processing equipment, with an annual production capacity of over.

We have obtained multiple international certifications such as AS9100D (Aerospace), ISO9001, IATF1649 (Automotive), ISO13485 (Medical Devices), FDA, RoHS, REACH, SGS , and our products are fully traceable . Our customers cover multiple high-threshold industries in over 60 countries and regions , including aerospace, medical, semiconductor, electronics, food, and new energy vehicles. We are committed to becoming a global leader in PEEK solutions.

27 Utility Model Patents

40+ Extrusion Lines + Cleanroom

30000+ Global Customers | 300 Million+ RMB Sales

18+ Years of Experience | 40+ Global Employees

AS9100D / ISO13485 / IATF16949 etc.

Serve 60+ Countries

Contact Us Now and Enjoy a One-Stop Solution!Fill the Form to Get a Quote, Product Manual, Performance Parameters, Custom Solutions, Technical Consultation, and Samples