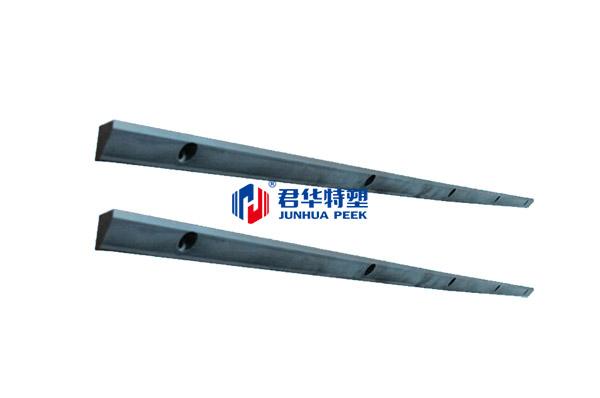

Junhua was founded in 2007 and specializes in the development, production, and sale of high-performance engineering plastics, particularly PEEK, PI, PPSU, and other special polymers. The company has a modern factory occupying 15,000+ square meters , with 40+ extrusion lines ,Complete injection molding and CNC processing equipment, with an annual production capacity of over.

We have obtained multiple international certifications such as AS9100D (Aerospace), ISO9001, IATF1649 (Automotive), ISO13485 (Medical Devices), FDA, RoHS, REACH, SGS , and our products are fully traceable . Our customers cover multiple high-threshold industries in over 60 countries and regions , including aerospace, medical, semiconductor, electronics, food, and new energy vehicles. We are committed to becoming a global leader in PEEK solutions.