Composite materials

Composite materials

PEEK Modified

lending modification is usually the most commonly used modification method for PEEK materials. Generally, fibers, metal oxides, inorganic fillers and other high molecular polymers such as PTFE can be added to the raw materials. The PEEK composite material prepared by this method can improve the defects of PEEK by using the composite effect, and improve the comprehensive properties of the material to a great extent.

Composite materials

Types of PEEK Modification

UNFILLED PEEK has excellent physical and chemical properties in its own right. Its characteristics of high strength, high toughness, corrosion resistance, high temperature resistance, good insulation, high purity basically meet most of the industrial environment.

Glass Fiber Filled PEEK

The most commonly used glass fiber filled peek content is 30%. The name of this material in Junhua is

PEEK5600GF30. Compared with PEEK unfilled, the PEEK material filled with glass fiber can improve higher

hardness, strength and better heat resistance. The thermal deformation temperature of PEEK filled with

glass fiber can be increased from 160 ℃ to over 300℃. Compared with this, the disadvantages of glass

fiber modification are that it is more difficult to process, and the toughness and electrical properties

are decreased compared with PEEK unfilled.

According to the liquidity, it can be subdivided into:

PEEK3600GF30; PEEK5600GF30; PEEK7600GF30;

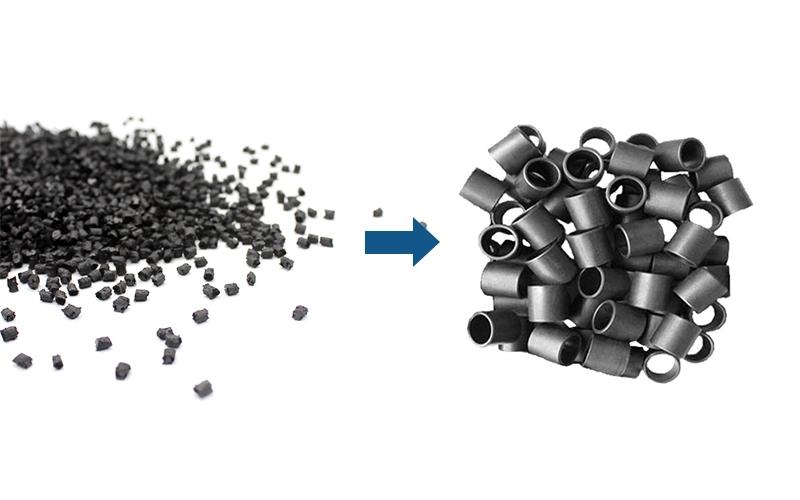

Carbon Fiber Filled PEEK

CThe most commonly used carbon fiber filled peek content is 30%. The name of this material in Junhua is

PEEK5600CF30. Compared with PEEK unfilled, the PEEK material filled with carbon fiber can improve higher

hardness, strength, better heat resistance and friction characteristics. The modified peek filled with

carbon fiber can be increased from 160 ℃ to over 300℃. Compared with this, the disadvantages of its

carbon fiber modification are that it is more difficult to process, and the toughness is reduced. At the

same time, due to the addition of carbon fiber, it has conductive characteristics.

According to the liquidity, it can be subdivided into:

PEEK3600CF30; PEEK5600CF30; PEEK7600CF30;

PEEK HPV

PEEK HPV is a peek material with low friction coefficient and good wear resistance. Among them, peek

accounts for 70%, PTFE accounts for 10%, graphite accounts for 10%, and carbon fiber accounts for 10%.

The name of this material in Junhua is PEEK5600LF30. The filling of graphite and PTFE can well reduce

the friction coefficient of the material, and can still reduce the energy consumption and noise in the

use process without using the lubricating medium; The addition of carbon fiber can improve the rigidity

of the material. Compared with other brands, its disadvantage is that its brittleness is large, that is,

its impact strength is small.

According to the liquidity, it can be subdivided into:

PEEK3600LF30; PEEK5600LF30; PEEK7600LF30;

Products

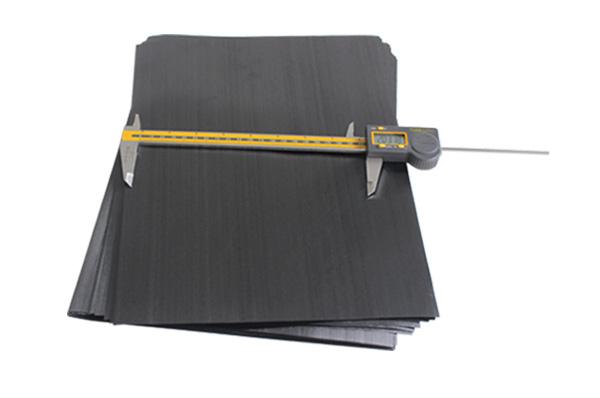

Continuous CF/PEEK thermoplastic composite sheet

CF/PEEK composite sheet

CF/PEEK composite support buckle

CF/PEEK composite prepreg tape

PEEK composite prepreg tape

Continuous carbon fiber CF/PEEK composite plate

Advantages

Choosing Junhua means choosing a partner with a complete industrial chain, strong technology research and development capabilities, an efficient production system, strict quality assurance, and excellent customer support.

Industry Deep Dive

18 years of experience in high-performance engineering plastics, serving high-barrier industries such as aerospace and medical, trusted globally.

Complete Industry Chain

From aggregation to processing, a one-stop PEEK solution, simplifying purchases and reducing risks.

Technology Research and Development

12 items of invention patents, 27 items of utility model patents, with collaboration with universities, continuous innovation.

Production Capability

40+ high-efficiency extrusion lines, 500+ professional teams, quick response to global demands.

Quality Assurance

Strict quality control, product traceability from aggregation to processing, three-dimensional detection, COA quality report.

Customer Support

Material selection, mold design, custom processing, and complete after-sales support, becoming your strategic partner.

Service

Junhua offers one-stop PEEK solutions from design to after-sales, ensuring quality, innovation, and customer satisfaction.

Design and processing

Junhua offers injection molding, machining, and extrusion solutions to optimize design and cost.

Material selection

Junhua specializes in PEEK with multiple grades and recommends the best engineering plastics for your needs.

Measurement

Junhua uses high-precision instruments to provide customers with accurate drawings.

Sampling

Junhua supplies samples for testing and refines designs until approval for mass production.

Mass Production

Junhua controls raw materials, processes, and inspections to ensure consistent product quality.

Quality Control

Junhua follows ISO9001 standards and provides full inspection reports as required.

Improve

Junhua continuously optimizes designs and processes through improvement systems and case experience.

After-sales Service

Junhua offers complete after-sales support to resolve technical issues and protect customer interests.

Contact Us

Certificate

About Us

Junhua was founded in 2007 and specializes in the development, production, and sale of high-performance engineering plastics, particularly PEEK, PI, PPSU, and other special polymers. The company has a modern factory occupying 15,000+ square meters , with 40+ extrusion lines ,Complete injection molding and CNC processing equipment, with an annual production capacity of over.

We have obtained multiple international certifications such as AS9100D (Aerospace), ISO9001, IATF1649 (Automotive), ISO13485 (Medical Devices), FDA, RoHS, REACH, SGS , and our products are fully traceable . Our customers cover multiple high-threshold industries in over 60 countries and regions , including aerospace, medical, semiconductor, electronics, food, and new energy vehicles. We are committed to becoming a global leader in PEEK solutions.

12 Patents for Invention

27 Utility Model Patents

15,000+㎡ Factory

40+ Extrusion Lines + Cleanroom

60+ Countries

30000+ Global Customers | 300 Million+ RMB Sales

500+ Team Members

18+ Years of Experience | 40+ Global Employees

Multiple International Certifications

AS9100D / ISO13485 / IATF16949 etc.

1000+ Global Partners

Serve 60+ Countries