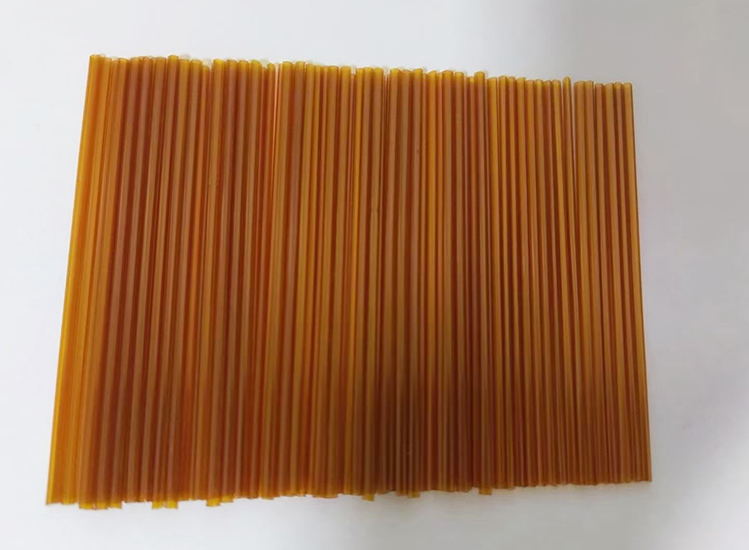

PI(polyimide) Tube

Thermoplastic polyimide (TPI) is a polymer material with excellent properties. It is widely used in medical, nuclear power and other fields due to its high temperature resistance, low temperature resistance, solvent resistance, radiation resistance and other properties.

Polyimide (PI) is an organic polymer material with excellent comprehensive properties. It can withstand high temperatures above 400°C. It has a long-term use temperature range of -200~300°C. It has no obvious melting point and has high insulation performance. It is an F to H class insulating material. Sleeves of this material have good electrical, physical and mechanical insulation properties. The casing has significant radiation resistance and flexibility at extremely high and low temperatures.

Features:

1) Good dimensional stability, the accuracy can be stabilized at ±0.03mm, and the tube wall thickness is 0.05mm-0.5mm.

2) Good heat resistance and thermal insulation, no brittleness at low temperature, and can be used for a long time at 250℃.

3) Good insulation performance, dielectric strength not less than 300kv/mm.

4) Good mechanical properties, tensile strength not less than 150MPa, tensile elongation not less than 10%.

5) Good chemical resistance, resistant to most solvents except strong acid and alkali solutions.

6) Good sterilization properties, can withstand various disinfection methods such as ethylene oxide, high temperature and high pressure, and irradiation.

7) Strong bonding properties. After surface treatment, the material can have good bonding strength with metals and other materials.

PI(polyimide) Tube Application

As a pipe with geometric dimensions, electrical, mechanical and precision, it can be used in small space, harsh high and low temperature environment, complex electromagnetic and radiation environment and other use conditions, such as organisms and underground, nuclear power plants, industrial facilities, instruments and equipment, etc., as protective casing, insulating casing, gas and liquid conduit, etc.

It is suitable for various medical catheters, including nerve catheters, implantable catheters, cardiac catheters, etc. Due to its high temperature resistance, it has advantages in processing and high temperature preoperative treatment. Because of its better mechanical properties and chemical stability, it is suitable for more complex medical processes, such as catheters that remain in the body for a long time.

Application examples:

Thermistor insulation sleeves, electronic probe sleeves, temperature sensor sleeves, electric heating element sleeves, precision conduits for high-temperature corrosive liquids and gases, etc.

Contact Us

Features & Advantages of PI

Ultra-high temperature polyimide (PI) polymer characteristics and advantages

UL certified for long-term use at 260℃; maintains strength even at 300℃.

Excellent durability under high temp, heavy load and corrosive conditions.

Low friction — works oil-free and in oil, water, steam, mild acids/alkalis.

Insoluble in common solvents; resists organic and inorganic chemicals.

Superior mechanical strength, rigidity and surface hardness.

Supports injection molding, machining, bonding and ultrasonic welding.

Works for thousands of hours in steam above 250℃ or pressurized water.

UL94 V-0 at 1.45 mm thickness without additives.

Produces very low smoke and toxic gases when burned.

Stable electrical performance across wide temp/frequency ranges.

Retains mechanical properties under high-dose gamma radiation.

Excellent dimensional stability under demanding conditions.

PI Properties Table

Ultra-high temperature polyimide (PI) polymer performance table

| Test Item | Test Standard | Unit | JHPI-10 | JHPI-10-21 | JHPI-10-22 | JHPI-HT | JHPI-YS | JSJHTPI-01 | JSJHTPI-02 |

| Density | ISO 1183 | g/cm3 | 1.40 | 1.43 | 1.7 | 1.4 | 1.36 | 1.32 | 1.36 |

| Tensile Strength | ISO 527 | Mpa | 96 | 90 | 60 | 92 | 121 | 90 | 97 |

| Elongation at Break | ISO 527 | % | 10 | 5 | 2.5 | 8 | 13 | 8 | 8 |

| Flexural Strength | ISO 178 | Mpa | 148 | 126 | 90 | 140 | 171 | 130 | 138 |

| Charpy Impact Strength | ISO 179 | MPa | 90 | 135 | 13 | 88 | No Break | 100 | No Break |

| Heat Deflection Temperature | ISO 75-1/-2 | ℃ | 300 | 300 | 300 | 320 | 255 | 230 | 250 |

| Continuous Service Temp. | UL746B | ℃ | 350 | 350 | 350 | 380 | 250 | 250 | 250 |

High-Performance Polyimide (PI) Solutions

Discover the versatile applications of high-temperature polyimide (PI) polymer, a material engineered for extreme environments and superior performance.

Key Characteristics & Applications

High-temperature polyimide is a high-performance polymer widely used across various industries, including automotive, semiconductors, electronics, and more. Its exceptional properties make it a go-to material for demanding applications.

-

Low friction and wear-resistant components under high speed and pressure.

-

Excellent creep or plastic deformation resistance.

-

Superb self-lubricating or oil-lubricating properties.

-

Liquid sealing components for high-temperature and high-pressure environments.

-

High bending, tensile, and impact strength.

-

Corrosion, radiation, and rust-resistant components.

-

Components for long-term use at temperatures above 300°C, with short-term resistance up to 400-450°C.

-

High-temperature structural adhesives for extreme conditions.

-

Microelectronics applications including stress-buffering coatings and dielectric films.

Typical Products

- Mold hot runner insulation plates and rings

- Piston rings, valve seats

- Chip test sockets

- Copier separation claws

- Laser imprinting rollers

- Semiconductor chip nozzles

- Semiconductor industry fixtures and jigs

- Gas chromatography seals

- Rolling, sliding, and thrust washers

- Plasma torch vortex rings

- Gears, Automotive engine gaskets

- Glass industry brackets

- Microwave components

Application Industries

- Aerospace

- Medical devices

- Analytical and testing equipment

- Petrochemicals

- Gears and seals

- Electronics, Semiconductors, Photovoltaics, FPD

- Food processing, packaging, and beverage filling

- New energy vehicles

- Textile printing and dyeing machinery

- Composites

- General machinery