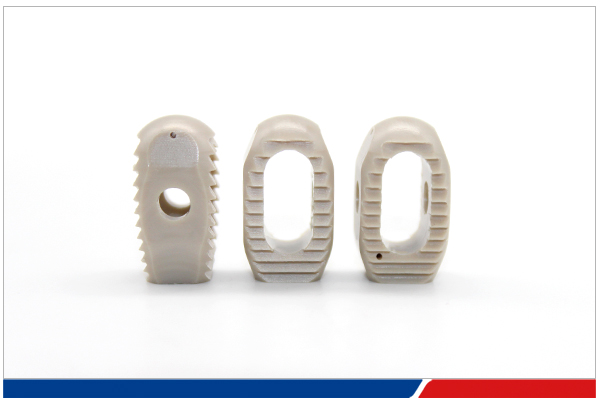

PEEK spinal fusion cage/intervertebral fusion cage is made of PEEK material and can be implanted in the intervertebral space of the cervical or lumbar spine or used for thoracic and lumbar vertebral replacement and restoration of height lost due to vertebral lesions and damage.

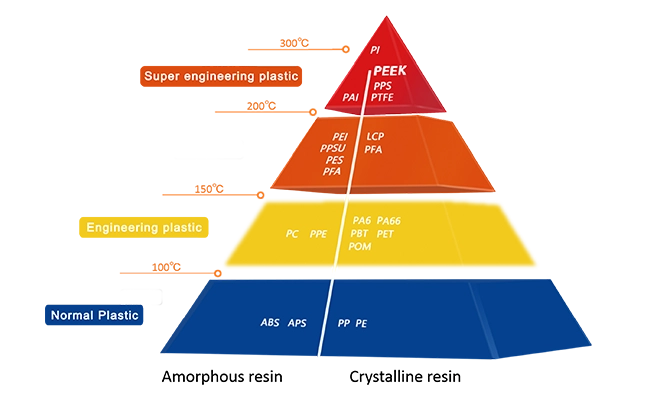

PEEK material is a new type of implant-grade material. Its scientific name is polyetheretherketone. As a member of special engineering plastics, PEEK (polyetheretherketone) has excellent comprehensive performance (easy molding, corrosion resistance, etc.) compared with other special engineering plastics (such as PPS, PAI, PI, PTFE, etc.). Its good biocompatibility, high purity, chemical inertness and elastic modulus similar to that of human bones make it known as a new generation of orthopedic implant materials after titanium alloys. After injection molding, it is suitable for repairing soft tissue injuries in joints such as shoulder joints, ankle joints, knee joints, hip joints, and wrist joints. It can be implanted in the intervertebral space of the cervical or lumbar vertebrae or used for thoracic and lumbar vertebral replacement and restoration of height lost due to vertebral lesions.

Features:

(1) Made of PEEK material, it is high in strength and radiolucent. The images during CT examination will be clearer and the postoperative repair status can be seen.

(2) High temperature resistance and poor heat conduction. It is more comfortable after peek material repair.

(3) PEEK material has good biocompatibility and its modulus is similar to that of human bone.

PEEK biocompatibility testing

Arthroscopic surgery has made great progress in the United States and other countries since the 1970s. In the past few decades, arthroscopy has had a revolutionary impact on the diagnosis and treatment of intra-articular diseases. Arthroscopy allows for a comprehensive observation of the intra-articular structure, which is more detailed than open surgery, and many intra-articular structures and lesions can be directly observed.

Some people call arthroscopy, fracture fixation and artificial joint replacement the three major advances in orthopedics in the 20th century. The first generation of shoulder arthroscopy equipment used stainless steel and titanium anchors, both of which failed mainly due to the breakage of the sutures in the metal eyelets.

In order to eliminate the risk of implant migration and reduce accidental cartilage damage, there has been a shift toward the use of bioresorbable anchors. Despite their great clinical success, failures in the clinical use of bioresorbable anchors have been reported due to rapid degradation, osteolysis and arthropathy, synovitis, implant fragments, and cartilage damage.

The low mechanical strength of these polymers is the main concern for their use. PEEK is strong and ductile and can provide comparable strength to metals but with less risk of arthrosis or joint destruction due to third body wear after extra-bone dislocations. Another benefit is that it can be drilled through if revision surgery is required.

| PEEK | PPSU | PSU | TO | LIKE | PC | |

| preservative | Excellent | Excellent | Excellent | Not tested | Excellent | good |

| Bleach | Excellent | Excellent | Excellent | Excellent | Excellent | good |

| Glutaraldehyde | Excellent | Excellent | Excellent | Not tested | Excellent | good |

| Hydrogen peroxide (3%) | Excellent | Excellent | Excellent | Excellent | Excellent | good |

| Isopropyl alcohol | Excellent | Excellent | good | Excellent | Excellent | good |

| Phenols(2%) | Excellent | Excellent | good | Excellent | good | Excellent |

The company is equipped with a clean workshop for implantable PEEK, an implantable PEEK extrusion production line and a German imported micro injection molding machine. Precision injection molding gives the product better plasticity and toughness, and is not easy to break. At the same time, it has a complete industrial chain, which controls from the source to ensure the stability of the product and the reliability of quality.

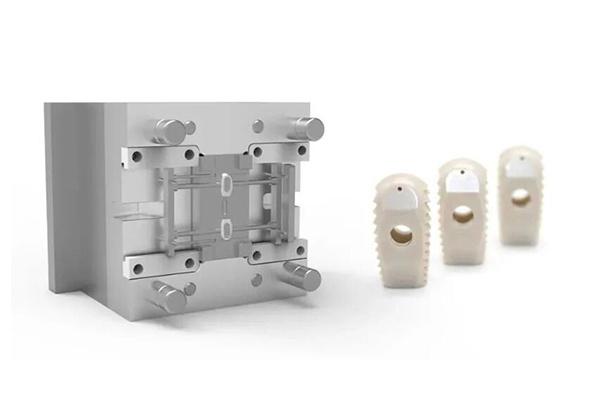

In 2021, in order to meet the development needs of domestic sports medicine, Changzhou Junhua Medical Technology Co., Ltd. actively cooperated with major domestic medical device units to develop precision injection molds for PEEK suture anchors in the sports medicine industry, which has the following advantages:

1) Experience in optimizing the design of PEEK product structure;

2) Design and manufacture of precision molds for difficult products such as PEEK anchors and spinal fusion devices;

3) PEEK medical implant-grade products are tested and sampled in the clean room;

4) Unique mold structure design saves the consumption of expensive PEEK;

5) The perfect after-sales service system is recognized by major domestic medical institutions.

Polyetheretherketone (PEEK) polymer material has gradually become a new trend in orthopedic repair materials due to its good biocompatibility, ability to perform complex shaping, ability to fit defect areas, good mechanical properties, good protective properties, and high postoperative comfort.

Based on the present and looking to the future. In 2021, Changzhou Junhua Medical officially launched the implantable PEEK project and is in the second round of inspection. The results of the inspection will be announced around June 2022. In order to better standardize implantable PEEK, a new implantable AKSOPEEK series brand will be added.

AKSO is the goddess of health in Greek mythology. We hope that China’s PEEK can serve the public more and hope that every injured patient can still enjoy a healthy life.

Our company has core technology and provides one-stop service for the entire PEEK industry chain. We can meet the audit requirements of medical customers and hope to provide you with sports medicine PEEK application solutions.

What is PEEK?

PEEK and its modified composite materials show excellent performance under high temperature and high humidity conditions. PEEK have excellent chemical corrosion resistance, self-lubricating, and wear-resistant properties, so it has become the most ideal material to replace copper alloys and ordinary rubber. Compared with them, PEEK has longer service life which can reduce equipment operating costs, improve equipment operating reliability.

High Temperature Performance

PEEK’s performance can remain stable in the temperature range from -196°C to 260°C. Under extreme working conditions, it can withstand 300″C for a short time. The performance of PEEK is still reliable even in high temperatures of several kilometers underground work environment.

High Strength and Wear Resistance

Compared with other plastics, PEEK is resistant to compression, impact and also have good fatigue resistance. PEEK is durable in mechanical equipment and wear-resistant environments.

Double the Service Life

PEEK sealing solutions can improve the part service life. Some domestic chemical companies use the PEEK5600FE20 polytetrafluoroethylene modified material designed by Junhua to replace the original material, the service life of the wear parts can even be extended by 1.3-3 times.

Corrosion Resistance

PEEK is chemically inert, and has no reaction to most acids, oils, greases and all other organic and inorganic solvents or enzymes, and can still maintain good strength and dimensional stability.

Self-lubricating

PEEK has low friction coefficient, low running resistance, can be used without oil in some working conditions. The equipment is cleaner, thus improving process reliability, improving energy efficiency and saving costs.

More dom in Design

Injection molds can be used for rapid injection molding of large quantities of complex special-shaped parts, and the cost is low compared to machining.

Contact Us

Common PEEK Grades and Properties

1. PEEK5600G (brown-gray/khaki) is made from pure polyetheretherketone resin and offers the best toughness and impact resistance of all PEEK grades. Pure PEEK can be sterilized using convenient methods (steam, dry heat, ethanol, and gamma-rays), and the raw materials used in its manufacture comply with EU and US FDA food compatibility regulations. These characteristics make it widely used in the medical, pharmaceutical, and food processing industries.

2. PEEK5600LF30 (black) The addition of PTFE, graphite, and carbon fiber makes PEEK5600LF30 a bearing-grade plastic. Its superior tribological properties (low coefficient of friction, wear resistance, and high peak pressure limit) make it an ideal material for this class of friction applications.

3. PEEK5600GF30 (Brown-Gray): This material is a reinforced grade of plastic filled with 30% glass fiber. It offers superior rigidity, creep resistance, and dimensional stability compared to PEEK, making it ideal for structural parts. It can withstand fixed loads for extended periods at high temperatures. If PEEK5600GF30 is used as a sliding component, its suitability should be carefully verified, as the glass fiber can scratch mating surfaces.

4. PEEK5600CF30 (Black): This material is reinforced with 30% carbon fiber. It offers superior mechanical properties (higher elastic modulus, mechanical strength, and creep resistance) and wear resistance compared to PEEK5600GF30. Furthermore, carbon fiber-reinforced plastic has 3.5 times the thermal conductivity of unreinforced PEEK, dissipating heat more quickly from the bearing surface.

Mechanical Properties

| Item | Test Standard or Instrument |

Unit | PEEK5600G 100% PEEK |

PEEK5600GF30 PEEK+30% glass fiber |

PEEK5600CF30 PEEK+30% carbon fiber |

PEEK5600LF30 PEEK+30% (carbon fiber +graphite+PTFE) |

PEEK5600FE20 PEEK+20%PTFE |

|---|---|---|---|---|---|---|---|

| Tensile Strength (23℃) | ISO 527 | MPa | 95 | 175 | 250 | 145 | 70 |

| Tensile Modulus (23℃) | ISO 527 | GPa | 3.8 | 11 | 23 | 12.5 | / |

| Elongation at Break (23℃) | ISO 527 | % | 35 | 2.0 | 1.5 | 2.2 | / |

| Flexural Strength (23℃) | ISO 178 | MPa | 155 | 235 | 350 | 220 | 118 |

| Flexural Modulus (23℃) | ISO 178 | GPa | 3.5 | 10 | 21 | 11 | / |

| Charpy Impact Strength (unnotched) | ISO 179/1U | kJ/m2 | No break | 55 | 45 | 32 | No break |

| Cantilever Beam Impact Strength (notched) | ISO 180/A | kJ/m2 | 4 | 6 | 6.5 | 4 | 6 |

Thermal Properties

| Item | Test Standard or Instrument |

Unit | PEEK5600G 100% PEEK |

PEEK5600GF30 PEEK+30% glass fiber |

PEEK5600CF30 PEEK+30% carbon fiber |

PEEK5600LF30 PEEK+30% (carbon fiber +graphite+PTFE) |

PEEK5600FE20 PEEK+20%PTFE |

|---|---|---|---|---|---|---|---|

| Melting Point | ISO11357 | ℃ | 343 | 343 | 343 | 343 | 343 |

| Glass Transition Temperature | ISO11357 | ℃ | 143 | 143 | 143 | 143 | 150 |

| Heat Deflection Temperature | ISO 75A/B | 1.8MPa. ℃ | 152 | 315 | 315 | 293 | 150 |

| Thermal Expansion Coefficient | ASTM D696 | ppm K-1 | 45 | 22 | 15 | 22 | 70 |

| Thermal Conductivity | ISO /CD22007-4 | W/(m·K) | 0.29 | 0.32 | 0.95 | 0.86 | / |

Electrical Properties

| Item | Test Standard or Instrument |

Unit | PEEK5600G 100% PEEK |

PEEK5600GF30 PEEK+30% glass fiber |

PEEK5600CF30 PEEK+30% carbon fiber |

PEEK5600LF30 PEEK+30% (carbon fiber +graphite+PTFE) |

PEEK5600FE20 PEEK+20%PTFE |

|---|---|---|---|---|---|---|---|

| Dielectric Strength (2mm) | IEC 60243-1 | kV/mm | 20 | 19 | / | / | 19 |

| Dielectric Constant | IEC 62631 | – | 3.0 | 3.3 | / | / | 2.7 |

| Surface Resistivity | GB/T31838.3 | Ω | 1015 | 1014 | / | / | 1015 |

| Volume Resistivity | IEC 62631 | Ω·cm | 1015 | 1015 | 105 | 106 | / |

Other Properties

| Item | Test Standard or Instrument |

Unit | PEEK5600G 100% PEEK |

PEEK5600GF30 PEEK+30% glass fiber |

PEEK5600CF30 PEEK+30% carbon fiber |

PEEK5600LF30 PEEK+carbon fiber +graphite+PTFE |

PEEK5600FE20 PEEK+20%PTFE |

|---|---|---|---|---|---|---|---|

| Color | / | / | Natural | Natural | Black | Black | Natural |

| Melt Flow Index (400℃, 2.16kg) | ISO 1133 | g/10min | 6-10 | 2-5 | 1-3 | 2-5 | / |

| Density | ISO 1183 | g/cm3 | 1.30±0.02 | 1.50±0.02 | 1.40±0.02 | 1.44±0.02 | 1.41±0.02 |

| Water Absorption (23℃, 24Hrs) | ISO 62-1 | % | 0.07 | 0.05 | 0.04 | 0.05 | 0.15 |

| Rockwell Hardness | / | HRR | 118 | 119 | 121 | 108 | 113 |

| Flammability Rating | UL 94 | / | V-0 | V-0 | V-0 | V-0 | / |

| Coefficient of Friction | ASTM D3702 | 100N-120rpm | 0.30-0.38 | 0.38-0.46 | 0.15-0.25 | 0.18-0.30 | 0.1-0.2 |

*This data is for reference and not a guarantee. For a more detailed data sheet, please contact our company’s technical department.

Service

Junhua offers one-stop PEEK solutions from design to after-sales, ensuring quality, innovation, and customer satisfaction.

Design and processing

Junhua offers injection molding, machining, and extrusion solutions to optimize design and cost.

Material selection

Junhua specializes in PEEK with multiple grades and recommends the best engineering plastics for your needs.

Measurement

Junhua uses high-precision instruments to provide customers with accurate drawings.

Sampling

Junhua supplies samples for testing and refines designs until approval for mass production.

Mass Production

Junhua controls raw materials, processes, and inspections to ensure consistent product quality.

Quality Control

Junhua follows ISO9001 standards and provides full inspection reports as required.

Improve

Junhua continuously optimizes designs and processes through improvement systems and case experience.

After-sales Service

Junhua offers complete after-sales support to resolve technical issues and protect customer interests.