PEEK gears used in reducers

Ordinary reducers usually use metal gears. However, with the diversification of people’s needs, traditional metal gears can no longer meet people’s requirements for gears. In this case, the emergence of PEEK gears has solved this problem well.

A typical reduction gear consists of an internal gear, an external gear, and an output unit. The external gear must be very strong and flexible to prevent damage caused by long-term rotation. The tooth shape of a metal reduction gear is precise and symmetrical, but its flexibility is reduced due to the inherent properties of metal.

PEEK material is a high-temperature special engineering plastic. The PEEK reduction gears made of it have the following advantages over ordinary metal gears: small size, high torque, low noise, full speed ratio, stable performance, instantaneous conversion, high efficiency, energy saving and low heat generation. The power-carrying part of the motor is sealed through the terminal box, which is dust-proof and moisture-proof, light weight and easy to install.

PEEK gear characteristics and advantages:

◆ High temperature resistance – the long-term use temperature certified by UL in the United States is 260°C. Even when the temperature reaches 300°C, it can still maintain good mechanical properties.

◆ Wear resistance – In many extremely harsh application environments such as high temperature, high load, and strong corrosion, PEEK polymers and their composite materials have good wear resistance.

◆ Self-lubricating – It has a low friction coefficient, can achieve oil-free lubrication, and can work for a long time in media such as oil, water, steam, weak acid and alkali.

◆ Corrosion resistance – insoluble in common solvents, and has good corrosion resistance to various organic and inorganic chemical reagents.

◆ High strength : It has good mechanical strength among plastics. It also has high rigidity and surface hardness.

◆ Easy to process – parts can be directly processed by injection molding process. Post-processing such as turning, milling, drilling, tapping, bonding and ultrasonic welding can be performed.

◆ Long life

◆ Low energy consumption

◆ Lightweight

◆ Low noise

Mechanical properties: PEEK is a high-performance polymer with excellent strength, stiffness and wear resistance. These properties make it very suitable for making robot parts such as joints, bearings and frames.

Chemical stability: PEEK has good corrosion resistance and high temperature resistance, and can work in harsh environments such as corrosive chemicals, high temperature and high humidity, etc. This makes PEEK an ideal material for making chemical protection robots and high temperature operation robots.

Lightweight: PEEK has a low density and is relatively light, which enables lightweight design of robots, thereby improving the mobility and energy efficiency of robots.

Electrical insulation: PEEK is an electrical insulating material. For electronic components and circuits that require insulation protection, PEEK can provide good protection.

Robotic Applications:

These characteristics make PEEK reduction gears have significant advantages in many fields, such as automation equipment, robots, logistics transmission and textile industries. Due to its high efficiency, stability and long life, PEEK reduction gears have become an ideal choice for many equipment, bringing great convenience to our industrial production and life.

Why is PEEK material an ideal choice for robot reducers

The robotics industry is growing rapidly, and the industry’s interest in motors and speed reducers has also increased. Recently, the demand for speed reducers has begun to increase in cutting-edge industries such as industrial robots.

In the robot power system, the reducer is a power transmission mechanism, which is mainly used to transmit the power of the servo motor, adjust the speed and torque, and accurately control the robot’s movement. It is known as the three core components of the robot together with the servo motor and controller. The reducers used in the field of robots are mostly RV reducers and harmonic reducers.

The reduction gear made of PEEK polymer has good performance and higher elasticity, and will not cause bonding problems between internal gears and external gears. At the same time, PEEK has excellent characteristics such as light weight and high cost-effectiveness.

Overall, reducers account for a large proportion of the total value of industrial robots, reaching 30% of the total cost. With the advancement of the robotics industry and the development of humanoid robots, the trend of increasing freedom and lightweighting has created a greater demand for reducers in the future.

Service scope:

In recent years, Junhua’s PEEK high-performance polymer materials have been successfully used as an alternative material in a wide range of industries. In response to the continued development of this trend, Junhua has sufficient resources to help customers in gear design, sample processing, mold opening and injection molding, mass production and application development. The existing processing technologies include gear hobbing, direct injection molding, gear shaping and other processes.

Junhua was established in 2007. Relying on its more than ten years of experience in PEEK R&D and production, it has become a joint-stock company with a full industrial chain that integrates PEEK resin raw material polymerization, PEEK sheet, rod, tube and other profile continuous extrusion molding, and finished parts R&D, production and sales. It has production and sales subsidiaries in many cities in China, and its products are sold to foreign and domestic markets such as Europe, America, and Southeast Asia.

The main trends in the industry are: improving performance and efficiency, reducing weight and achieving miniaturization while reducing costs. PEEK gear applications require finding new materials to replace existing metal materials or to improve typical polymer material solutions to meet the high performance requirements of future systems.

PEEK gears are widely used due to their advantages such as light weight, wear resistance, self-lubrication, low noise, corrosion resistance and high temperature resistance.

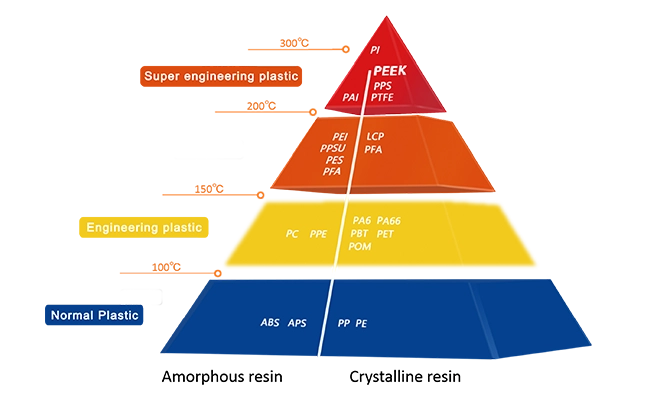

What is PEEK?

PEEK and its modified composite materials show excellent performance under high temperature and high humidity conditions. PEEK have excellent chemical corrosion resistance, self-lubricating, and wear-resistant properties, so it has become the most ideal material to replace copper alloys and ordinary rubber. Compared with them, PEEK has longer service life which can reduce equipment operating costs, improve equipment operating reliability.

High Temperature Performance

PEEK’s performance can remain stable in the temperature range from -196°C to 260°C. Under extreme working conditions, it can withstand 300″C for a short time. The performance of PEEK is still reliable even in high temperatures of several kilometers underground work environment.

High Strength and Wear Resistance

Compared with other plastics, PEEK is resistant to compression, impact and also have good fatigue resistance. PEEK is durable in mechanical equipment and wear-resistant environments.

Double the Service Life

PEEK sealing solutions can improve the part service life. Some domestic chemical companies use the PEEK5600FE20 polytetrafluoroethylene modified material designed by Junhua to replace the original material, the service life of the wear parts can even be extended by 1.3-3 times.

Corrosion Resistance

PEEK is chemically inert, and has no reaction to most acids, oils, greases and all other organic and inorganic solvents or enzymes, and can still maintain good strength and dimensional stability.

Self-lubricating

PEEK has low friction coefficient, low running resistance, can be used without oil in some working conditions. The equipment is cleaner, thus improving process reliability, improving energy efficiency and saving costs.

More dom in Design

Injection molds can be used for rapid injection molding of large quantities of complex special-shaped parts, and the cost is low compared to machining.

Contact Us

Common PEEK Grades and Properties

1. PEEK5600G (brown-gray/khaki) is made from pure polyetheretherketone resin and offers the best toughness and impact resistance of all PEEK grades. Pure PEEK can be sterilized using convenient methods (steam, dry heat, ethanol, and gamma-rays), and the raw materials used in its manufacture comply with EU and US FDA food compatibility regulations. These characteristics make it widely used in the medical, pharmaceutical, and food processing industries.

2. PEEK5600LF30 (black) The addition of PTFE, graphite, and carbon fiber makes PEEK5600LF30 a bearing-grade plastic. Its superior tribological properties (low coefficient of friction, wear resistance, and high peak pressure limit) make it an ideal material for this class of friction applications.

3. PEEK5600GF30 (Brown-Gray): This material is a reinforced grade of plastic filled with 30% glass fiber. It offers superior rigidity, creep resistance, and dimensional stability compared to PEEK, making it ideal for structural parts. It can withstand fixed loads for extended periods at high temperatures. If PEEK5600GF30 is used as a sliding component, its suitability should be carefully verified, as the glass fiber can scratch mating surfaces.

4. PEEK5600CF30 (Black): This material is reinforced with 30% carbon fiber. It offers superior mechanical properties (higher elastic modulus, mechanical strength, and creep resistance) and wear resistance compared to PEEK5600GF30. Furthermore, carbon fiber-reinforced plastic has 3.5 times the thermal conductivity of unreinforced PEEK, dissipating heat more quickly from the bearing surface.

Mechanical Properties

| Item | Test Standard or Instrument |

Unit | PEEK5600G 100% PEEK |

PEEK5600GF30 PEEK+30% glass fiber |

PEEK5600CF30 PEEK+30% carbon fiber |

PEEK5600LF30 PEEK+30% (carbon fiber +graphite+PTFE) |

PEEK5600FE20 PEEK+20%PTFE |

|---|---|---|---|---|---|---|---|

| Tensile Strength (23℃) | ISO 527 | MPa | 95 | 175 | 250 | 145 | 70 |

| Tensile Modulus (23℃) | ISO 527 | GPa | 3.8 | 11 | 23 | 12.5 | / |

| Elongation at Break (23℃) | ISO 527 | % | 35 | 2.0 | 1.5 | 2.2 | / |

| Flexural Strength (23℃) | ISO 178 | MPa | 155 | 235 | 350 | 220 | 118 |

| Flexural Modulus (23℃) | ISO 178 | GPa | 3.5 | 10 | 21 | 11 | / |

| Charpy Impact Strength (unnotched) | ISO 179/1U | kJ/m2 | No break | 55 | 45 | 32 | No break |

| Cantilever Beam Impact Strength (notched) | ISO 180/A | kJ/m2 | 4 | 6 | 6.5 | 4 | 6 |

Thermal Properties

| Item | Test Standard or Instrument |

Unit | PEEK5600G 100% PEEK |

PEEK5600GF30 PEEK+30% glass fiber |

PEEK5600CF30 PEEK+30% carbon fiber |

PEEK5600LF30 PEEK+30% (carbon fiber +graphite+PTFE) |

PEEK5600FE20 PEEK+20%PTFE |

|---|---|---|---|---|---|---|---|

| Melting Point | ISO11357 | ℃ | 343 | 343 | 343 | 343 | 343 |

| Glass Transition Temperature | ISO11357 | ℃ | 143 | 143 | 143 | 143 | 150 |

| Heat Deflection Temperature | ISO 75A/B | 1.8MPa. ℃ | 152 | 315 | 315 | 293 | 150 |

| Thermal Expansion Coefficient | ASTM D696 | ppm K-1 | 45 | 22 | 15 | 22 | 70 |

| Thermal Conductivity | ISO /CD22007-4 | W/(m·K) | 0.29 | 0.32 | 0.95 | 0.86 | / |

Electrical Properties

| Item | Test Standard or Instrument |

Unit | PEEK5600G 100% PEEK |

PEEK5600GF30 PEEK+30% glass fiber |

PEEK5600CF30 PEEK+30% carbon fiber |

PEEK5600LF30 PEEK+30% (carbon fiber +graphite+PTFE) |

PEEK5600FE20 PEEK+20%PTFE |

|---|---|---|---|---|---|---|---|

| Dielectric Strength (2mm) | IEC 60243-1 | kV/mm | 20 | 19 | / | / | 19 |

| Dielectric Constant | IEC 62631 | – | 3.0 | 3.3 | / | / | 2.7 |

| Surface Resistivity | GB/T31838.3 | Ω | 1015 | 1014 | / | / | 1015 |

| Volume Resistivity | IEC 62631 | Ω·cm | 1015 | 1015 | 105 | 106 | / |

Other Properties

| Item | Test Standard or Instrument |

Unit | PEEK5600G 100% PEEK |

PEEK5600GF30 PEEK+30% glass fiber |

PEEK5600CF30 PEEK+30% carbon fiber |

PEEK5600LF30 PEEK+carbon fiber +graphite+PTFE |

PEEK5600FE20 PEEK+20%PTFE |

|---|---|---|---|---|---|---|---|

| Color | / | / | Natural | Natural | Black | Black | Natural |

| Melt Flow Index (400℃, 2.16kg) | ISO 1133 | g/10min | 6-10 | 2-5 | 1-3 | 2-5 | / |

| Density | ISO 1183 | g/cm3 | 1.30±0.02 | 1.50±0.02 | 1.40±0.02 | 1.44±0.02 | 1.41±0.02 |

| Water Absorption (23℃, 24Hrs) | ISO 62-1 | % | 0.07 | 0.05 | 0.04 | 0.05 | 0.15 |

| Rockwell Hardness | / | HRR | 118 | 119 | 121 | 108 | 113 |

| Flammability Rating | UL 94 | / | V-0 | V-0 | V-0 | V-0 | / |

| Coefficient of Friction | ASTM D3702 | 100N-120rpm | 0.30-0.38 | 0.38-0.46 | 0.15-0.25 | 0.18-0.30 | 0.1-0.2 |

*This data is for reference and not a guarantee. For a more detailed data sheet, please contact our company’s technical department.

Service

Junhua offers one-stop PEEK solutions from design to after-sales, ensuring quality, innovation, and customer satisfaction.

Design and processing

Junhua offers injection molding, machining, and extrusion solutions to optimize design and cost.

Material selection

Junhua specializes in PEEK with multiple grades and recommends the best engineering plastics for your needs.

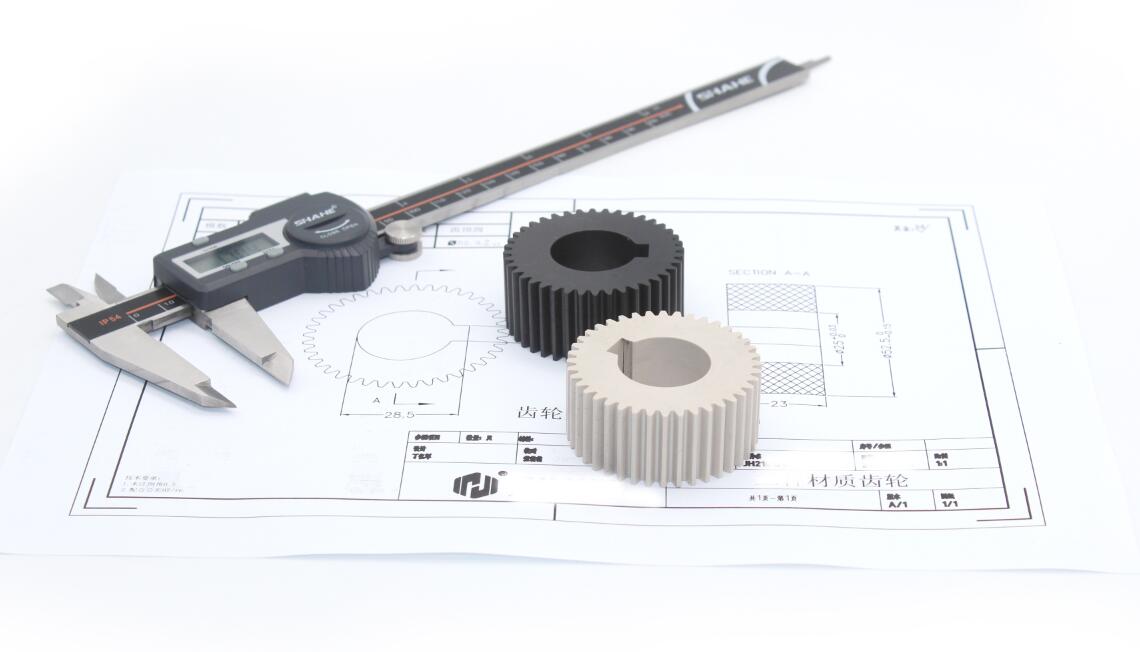

Measurement

Junhua uses high-precision instruments to provide customers with accurate drawings.

Sampling

Junhua supplies samples for testing and refines designs until approval for mass production.

Mass Production

Junhua controls raw materials, processes, and inspections to ensure consistent product quality.

Quality Control

Junhua follows ISO9001 standards and provides full inspection reports as required.

Improve

Junhua continuously optimizes designs and processes through improvement systems and case experience.

After-sales Service

Junhua offers complete after-sales support to resolve technical issues and protect customer interests.