1. Overview:

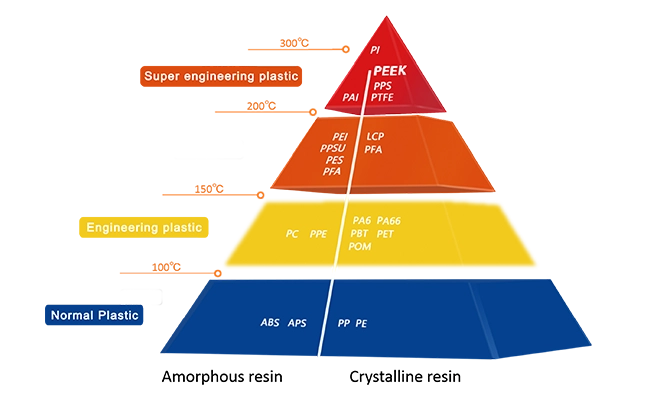

PEEK is a high temperature resistant thermoplastic with a high glass transition temperature (143°C) and melting point (334°C). Its load thermal deformation temperature is as high as 316°C (30% glass fiber or carbon fiber reinforced grades).

2. Detailed description:

Main characteristics and advantages of PEEK:

1: High temperature resistance The long-term use temperature of the US UL certification is 260°C. Even when the temperature reaches 300°C, it can still maintain excellent mechanical properties

2: Wear resistance In many extremely harsh application environments such as high temperature, high load, and strong corrosion, PEEK polymers and their composite materials have better wear resistance.

3: Self-lubrication has a lower friction coefficient, can achieve oil-free lubrication, and can work for a long time in media such as oil, water, steam, weak acid and alkali.

4: Corrosion resistance : Insoluble in common solvents, and has good corrosion resistance to various organic and inorganic chemical reagents.

5: High strength : It has good mechanical strength among plastics. It also has high rigidity and surface hardness.

6: Easy to process: Parts can be directly processed by injection molding process. Post-processing such as turning, milling, drilling, tapping, bonding and ultrasonic welding can be performed.

7: Hydrolysis resistance: Even when immersed in steam at a temperature exceeding 250°C or in high-pressure water, PEEK products can still work continuously for thousands of hours without significant performance degradation.

8: Flame retardancy Without using any additives, the flammability grade of the 1.45mm thick PEEK sample is UL94V-0.

9: Low smoke and non-toxic The amount of smoke and toxic gas during combustion is extremely low.

10: Electrical properties can maintain stable and excellent electrical properties within a wide temperature and frequency range.

11: Radiation resistance: It has strong resistance to high-dose gamma-ray radiation, and its mechanical properties can be fully retained, so it can be used as radiation-resistant parts.

12: Dimensional stability

What is PEEK?

PEEK and its modified composite materials show excellent performance under high temperature and high humidity conditions. PEEK have excellent chemical corrosion resistance, self-lubricating, and wear-resistant properties, so it has become the most ideal material to replace copper alloys and ordinary rubber. Compared with them, PEEK has longer service life which can reduce equipment operating costs, improve equipment operating reliability.

High Temperature Performance

PEEK’s performance can remain stable in the temperature range from -196°C to 260°C. Under extreme working conditions, it can withstand 300″C for a short time. The performance of PEEK is still reliable even in high temperatures of several kilometers underground work environment.

High Strength and Wear Resistance

Compared with other plastics, PEEK is resistant to compression, impact and also have good fatigue resistance. PEEK is durable in mechanical equipment and wear-resistant environments.

Double the Service Life

PEEK sealing solutions can improve the part service life. Some domestic chemical companies use the PEEK5600FE20 polytetrafluoroethylene modified material designed by Junhua to replace the original material, the service life of the wear parts can even be extended by 1.3-3 times.

Corrosion Resistance

PEEK is chemically inert, and has no reaction to most acids, oils, greases and all other organic and inorganic solvents or enzymes, and can still maintain good strength and dimensional stability.

Self-lubricating

PEEK has low friction coefficient, low running resistance, can be used without oil in some working conditions. The equipment is cleaner, thus improving process reliability, improving energy efficiency and saving costs.

More dom in Design

Injection molds can be used for rapid injection molding of large quantities of complex special-shaped parts, and the cost is low compared to machining.

Contact Us

Common PEEK Grades and Properties

1. PEEK5600G (brown-gray/khaki) is made from pure polyetheretherketone resin and offers the best toughness and impact resistance of all PEEK grades. Pure PEEK can be sterilized using convenient methods (steam, dry heat, ethanol, and gamma-rays), and the raw materials used in its manufacture comply with EU and US FDA food compatibility regulations. These characteristics make it widely used in the medical, pharmaceutical, and food processing industries.

2. PEEK5600LF30 (black) The addition of PTFE, graphite, and carbon fiber makes PEEK5600LF30 a bearing-grade plastic. Its superior tribological properties (low coefficient of friction, wear resistance, and high peak pressure limit) make it an ideal material for this class of friction applications.

3. PEEK5600GF30 (Brown-Gray): This material is a reinforced grade of plastic filled with 30% glass fiber. It offers superior rigidity, creep resistance, and dimensional stability compared to PEEK, making it ideal for structural parts. It can withstand fixed loads for extended periods at high temperatures. If PEEK5600GF30 is used as a sliding component, its suitability should be carefully verified, as the glass fiber can scratch mating surfaces.

4. PEEK5600CF30 (Black): This material is reinforced with 30% carbon fiber. It offers superior mechanical properties (higher elastic modulus, mechanical strength, and creep resistance) and wear resistance compared to PEEK5600GF30. Furthermore, carbon fiber-reinforced plastic has 3.5 times the thermal conductivity of unreinforced PEEK, dissipating heat more quickly from the bearing surface.

Mechanical Properties

| Item | Test Standard or Instrument |

Unit | PEEK5600G 100% PEEK |

PEEK5600GF30 PEEK+30% glass fiber |

PEEK5600CF30 PEEK+30% carbon fiber |

PEEK5600LF30 PEEK+30% (carbon fiber +graphite+PTFE) |

PEEK5600FE20 PEEK+20%PTFE |

|---|---|---|---|---|---|---|---|

| Tensile Strength (23℃) | ISO 527 | MPa | 95 | 175 | 250 | 145 | 70 |

| Tensile Modulus (23℃) | ISO 527 | GPa | 3.8 | 11 | 23 | 12.5 | / |

| Elongation at Break (23℃) | ISO 527 | % | 35 | 2.0 | 1.5 | 2.2 | / |

| Flexural Strength (23℃) | ISO 178 | MPa | 155 | 235 | 350 | 220 | 118 |

| Flexural Modulus (23℃) | ISO 178 | GPa | 3.5 | 10 | 21 | 11 | / |

| Charpy Impact Strength (unnotched) | ISO 179/1U | kJ/m2 | No break | 55 | 45 | 32 | No break |

| Cantilever Beam Impact Strength (notched) | ISO 180/A | kJ/m2 | 4 | 6 | 6.5 | 4 | 6 |

Thermal Properties

| Item | Test Standard or Instrument |

Unit | PEEK5600G 100% PEEK |

PEEK5600GF30 PEEK+30% glass fiber |

PEEK5600CF30 PEEK+30% carbon fiber |

PEEK5600LF30 PEEK+30% (carbon fiber +graphite+PTFE) |

PEEK5600FE20 PEEK+20%PTFE |

|---|---|---|---|---|---|---|---|

| Melting Point | ISO11357 | ℃ | 343 | 343 | 343 | 343 | 343 |

| Glass Transition Temperature | ISO11357 | ℃ | 143 | 143 | 143 | 143 | 150 |

| Heat Deflection Temperature | ISO 75A/B | 1.8MPa. ℃ | 152 | 315 | 315 | 293 | 150 |

| Thermal Expansion Coefficient | ASTM D696 | ppm K-1 | 45 | 22 | 15 | 22 | 70 |

| Thermal Conductivity | ISO /CD22007-4 | W/(m·K) | 0.29 | 0.32 | 0.95 | 0.86 | / |

Electrical Properties

| Item | Test Standard or Instrument |

Unit | PEEK5600G 100% PEEK |

PEEK5600GF30 PEEK+30% glass fiber |

PEEK5600CF30 PEEK+30% carbon fiber |

PEEK5600LF30 PEEK+30% (carbon fiber +graphite+PTFE) |

PEEK5600FE20 PEEK+20%PTFE |

|---|---|---|---|---|---|---|---|

| Dielectric Strength (2mm) | IEC 60243-1 | kV/mm | 20 | 19 | / | / | 19 |

| Dielectric Constant | IEC 62631 | – | 3.0 | 3.3 | / | / | 2.7 |

| Surface Resistivity | GB/T31838.3 | Ω | 1015 | 1014 | / | / | 1015 |

| Volume Resistivity | IEC 62631 | Ω·cm | 1015 | 1015 | 105 | 106 | / |

Other Properties

| Item | Test Standard or Instrument |

Unit | PEEK5600G 100% PEEK |

PEEK5600GF30 PEEK+30% glass fiber |

PEEK5600CF30 PEEK+30% carbon fiber |

PEEK5600LF30 PEEK+carbon fiber +graphite+PTFE |

PEEK5600FE20 PEEK+20%PTFE |

|---|---|---|---|---|---|---|---|

| Color | / | / | Natural | Natural | Black | Black | Natural |

| Melt Flow Index (400℃, 2.16kg) | ISO 1133 | g/10min | 6-10 | 2-5 | 1-3 | 2-5 | / |

| Density | ISO 1183 | g/cm3 | 1.30±0.02 | 1.50±0.02 | 1.40±0.02 | 1.44±0.02 | 1.41±0.02 |

| Water Absorption (23℃, 24Hrs) | ISO 62-1 | % | 0.07 | 0.05 | 0.04 | 0.05 | 0.15 |

| Rockwell Hardness | / | HRR | 118 | 119 | 121 | 108 | 113 |

| Flammability Rating | UL 94 | / | V-0 | V-0 | V-0 | V-0 | / |

| Coefficient of Friction | ASTM D3702 | 100N-120rpm | 0.30-0.38 | 0.38-0.46 | 0.15-0.25 | 0.18-0.30 | 0.1-0.2 |

*This data is for reference and not a guarantee. For a more detailed data sheet, please contact our company’s technical department.

Service

Junhua offers one-stop PEEK solutions from design to after-sales, ensuring quality, innovation, and customer satisfaction.

Design and processing

Junhua offers injection molding, machining, and extrusion solutions to optimize design and cost.

Material selection

Junhua specializes in PEEK with multiple grades and recommends the best engineering plastics for your needs.

Measurement

Junhua uses high-precision instruments to provide customers with accurate drawings.

Sampling

Junhua supplies samples for testing and refines designs until approval for mass production.

Mass Production

Junhua controls raw materials, processes, and inspections to ensure consistent product quality.

Quality Control

Junhua follows ISO9001 standards and provides full inspection reports as required.

Improve

Junhua continuously optimizes designs and processes through improvement systems and case experience.

After-sales Service

Junhua offers complete after-sales support to resolve technical issues and protect customer interests.