PEEK5600UV Granules

As an advanced special engineering plastic, PEEK plays an important role in weight reduction, effectively extending the service life of components, and optimizing component utilization due to its good machinability, flame retardant, non-toxic, wear resistance, corrosion resistance, etc., and the promotion of downstream applications is accelerating.

Based on the excellent properties of PEEK materials, PEEK5600UV add high-efficiency ultraviolet absorbers through nano-modification technology, and the UV shielding efficiency exceeds 90%. In extreme ultraviolet environments such as strong radiation, high altitude, and tropics, it can maintain a high degree of color stability and no significant attenuation of mechanical properties, laying a solid foundation for the long-term stable application of materials, and has the advantages of good and long-term UV irradiation resistance, weather resistance and wide processing technology range.

Excellent UV resistance

In the accelerated aging test simulating extreme environments, after 21 days of alternating accelerated aging by 340nm ultraviolet (0.76W) irradiation and condensation, the PEEK5600UV chromatic aberration was significantly smaller than that of pure PEEK materials, and ΔELab decreased from 18.81 to 12.33, effectively avoiding the problem of material discoloration.

Good mechanical property retention

Also under the above accelerated aging test conditions, after 21 days, the mechanical properties of PEEK5600UV can still be maintained by more than 95%, far exceeding ordinary materials, providing strong support for product reliability and durability.

Excellent overall performance

PEEK5600UV has the inherent advantages of PEEK materials such as high temperature resistance (long-term resistance to 260°C), chemical corrosion resistance, high mechanical strength, etc., and has the characteristics of low outgassing, light weight (only half the density of aluminum alloy), and flame retardancy up to UL94 V-0 level.

Based on the above excellent performance, PEEK5600UV can be widely used in aerospace and satellites, new energy vehicles, 5G communications, industry, medical and other fields.

(1) Aerospace and satellites: Satellite solar panel brackets, drone shells and other components are exposed to strong ultraviolet rays in the universe for a long time, and ordinary materials are prone to brittleness and discoloration. PEEK5600UV has become the preferred material for radomes and other shells due to its radiation resistance, low outgassing, and lightweight (only half the density of aluminum alloy), which can increase the life of satellites by more than 3 times.

(2) New energy vehicles: Outdoor components such as electric vehicle charging pile shells and high-voltage connectors need to be exposed to the sun and rain. Traditional plastics (such as PA and PC) are prone to yellowing and cracking under long-term UV exposure, but the anti-aging properties of PEEK5600UV can effectively avoid this problem. At the same time, its flame retardancy (UL94 V-0 rating) also ensures charging safety.

(3) 5G communication and electronics: 5G base station radomes, optical fiber connectors and other outdoor devices have strict requirements for dielectric performance (dielectric constant <3.25) and UV resistance. PEEK5600UV can maintain signal stability in the range of -50°C~260°C, avoid dielectric loss caused by ultraviolet rays, and ensure communication quality.

(4) Chemical pipelines: outdoor valves and sensor housings need to resist ultraviolet rays and acid-alkali corrosion at the same time. PEEK5600UV’s chemical resistance and UV resistance allow it to achieve “zero maintenance” operation and reduce equipment maintenance costs.

(5) Medical devices: Artificial joints and dental instruments are prone to aging in ultraviolet disinfection scenarios. The biocompatibility and radiation resistance of PEEK5600UV ensure the long-term safety of the implant and improve the quality of life of patients.

| Test items | Test standards or instruments | unit | PEEK5600G |

|---|---|---|---|

| Mechanical properties | |||

| Tensile strength (23℃) | ISO 527-2/1B/50 | MPa | 95 |

| Tensile modulus (23℃) | ISO 527-2/1B/51 | GPa | 4.0 |

| Elongation at break (23℃) | ISO 527-2/1B/50 | % | 25 |

| Bending strength (23℃) | ISO 178 | MPa | 169 |

| Flexural modulus (23°C) | ISO 178 | GPa | 4.2 |

| Compression strength (23℃) | ISO 604 | MPa | 125 |

| Simple supported beam impact strength (unnotched) | ISO 179/U | KJ/m 2 | No break |

| Izod impact strength (notched) | ISO 180/A | KJ/m 2 | 6 |

| Thermal performance | |||

| Melting point | DSC | ℃ | 343 |

| Heat deformation temperature | ISO 75-1/-2 | ℃ | 155 |

| Continuous use temperature | UL 746B | ℃ | 260 |

| Coefficient of thermal expansion | ASTM D696 | ppm K-1 | 46 |

| Flammability rating | UL 94 | / | V-0 |

| Thermal conductivity | ISO 22007 | W/(m ·K) | 0.28 |

| Electrical properties | |||

| Dielectric strength | IEC 60243-1 | KV/mm | 18 |

| Dielectric constant | IEC 60250 | – | 3.2 |

| Surface resistance | IEC 61340 | Oh | 1016 |

| Lossy dielectric | IEC 60251 | – | 0.004 |

| Other performance | |||

| color | – | True Color | |

| Actual density | ISO 1183 | g/cm 3 | 1.30 |

| Water absorption rate (25℃.24Hrs) | ISO 62 | % | 0.05 |

| Molding shrinkage (25-24℃) | 3mm thickness, 170°C flow direction |

% | 1.0 |

| Perpendicular to the flow direction | % | 1.3 | |

| Poisson’s ratio | ISO 527-2 | 0.4 | |

| Rockwell hardness | GB/T 3398.2 | HRR | 118 |

| Friction coefficient | ASTM D3702 | m | 0.30-0.35 |

| Melt index | ISO 1133 | g/10min | 10 |

- Typical values are injection molding specifications. Please contact our technical department for more detailed specifications if necessary.

- These performance indicators cannot be used as material acceptance criteria.

Contact Us

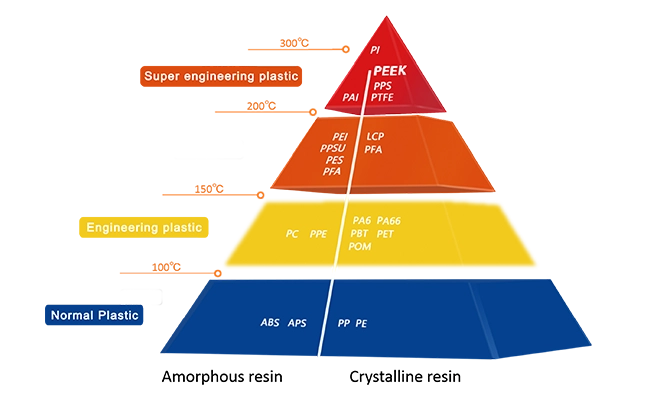

What is PEEK?

PEEK and its modified composite materials show excellent performance under high temperature and high humidity conditions. PEEK have excellent chemical corrosion resistance, self-lubricating, and wear-resistant properties, so it has become the most ideal material to replace copper alloys and ordinary rubber. Compared with them, PEEK has longer service life which can reduce equipment operating costs, improve equipment operating reliability.

High Temperature Performance

PEEK’s performance can remain stable in the temperature range from -196°C to 260°C. Under extreme working conditions, it can withstand 300″C for a short time. The performance of PEEK is still reliable even in high temperatures of several kilometers underground work environment.

High Strength and Wear Resistance

Compared with other plastics, PEEK is resistant to compression, impact and also have good fatigue resistance. PEEK is durable in mechanical equipment and wear-resistant environments.

Double the Service Life

PEEK sealing solutions can improve the part service life. Some domestic chemical companies use the PEEK5600FE20 polytetrafluoroethylene modified material designed by Junhua to replace the original material, the service life of the wear parts can even be extended by 1.3-3 times.

Corrosion Resistance

PEEK is chemically inert, and has no reaction to most acids, oils, greases and all other organic and inorganic solvents or enzymes, and can still maintain good strength and dimensional stability.

Self-lubricating

PEEK has low friction coefficient, low running resistance, can be used without oil in some working conditions. The equipment is cleaner, thus improving process reliability, improving energy efficiency and saving costs.

More dom in Design

Injection molds can be used for rapid injection molding of large quantities of complex special-shaped parts, and the cost is low compared to machining.