PEEK5600SWR Granules

PEEK5600SWR is a super-wear-resistant modified PEEK pellet that is free of tetrafluoroethylene and other halogen additives. It meets market requirements for being fluorine- and halogen-free and can be produced and processed by injection molding and extrusion.

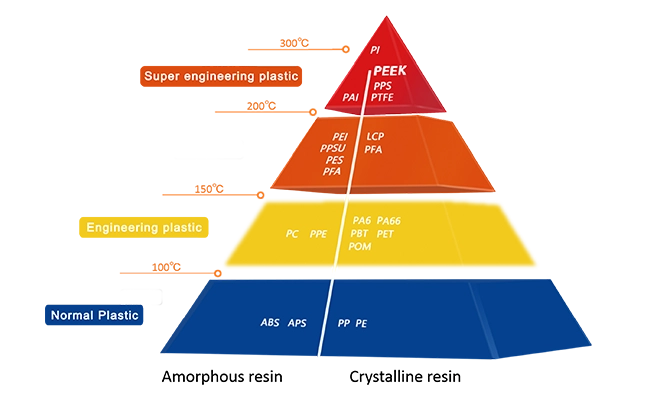

What is PEEK?

PEEK and its modified composite materials show excellent performance under high temperature and high humidity conditions. PEEK have excellent chemical corrosion resistance, self-lubricating, and wear-resistant properties, so it has become the most ideal material to replace copper alloys and ordinary rubber. Compared with them, PEEK has longer service life which can reduce equipment operating costs, improve equipment operating reliability.

High Temperature Performance

PEEK’s performance can remain stable in the temperature range from -196°C to 260°C. Under extreme working conditions, it can withstand 300″C for a short time. The performance of PEEK is still reliable even in high temperatures of several kilometers underground work environment.

High Strength and Wear Resistance

Compared with other plastics, PEEK is resistant to compression, impact and also have good fatigue resistance. PEEK is durable in mechanical equipment and wear-resistant environments.

Double the Service Life

PEEK sealing solutions can improve the part service life. Some domestic chemical companies use the PEEK5600FE20 polytetrafluoroethylene modified material designed by Junhua to replace the original material, the service life of the wear parts can even be extended by 1.3-3 times.

Corrosion Resistance

PEEK is chemically inert, and has no reaction to most acids, oils, greases and all other organic and inorganic solvents or enzymes, and can still maintain good strength and dimensional stability.

Self-lubricating

PEEK has low friction coefficient, low running resistance, can be used without oil in some working conditions. The equipment is cleaner, thus improving process reliability, improving energy efficiency and saving costs.

More dom in Design

Injection molds can be used for rapid injection molding of large quantities of complex special-shaped parts, and the cost is low compared to machining.

| Test items | Test standards or instruments | unit | PEEK5600SWR |

|---|---|---|---|

| Mechanical properties | |||

| Tensile strength (23℃) | ISO 527-2/1B/50 | MPa | 170 |

| Tensile modulus (23℃) | ISO 527-2/1B/51 | GPa | 13 |

| Elongation at break (23℃) | ISO 527-2/1B/50 | % | 4 |

| Bending strength (23℃) | ISO 178 | MPa | 270 |

| Flexural modulus (23°C) | ISO 178 | GPa | 10 |

| Compression strength (23℃) | ISO 604 | MPa | / |

| Simple supported beam impact strength (unnotched) | ISO 179/U | KJ/m 2 | 30 |

| Izod impact strength (notched) | ISO 180/A | KJ/m 2 | / |

| Thermal performance | |||

| Melting point | DSC | ℃ | 343 |

| Heat deformation temperature | ISO 75-1/-2 | ℃ | 330 |

| Continuous use temperature | UL 746B | ℃ | 260 |

| Coefficient of thermal expansion | ASTM D696 | ppm K-1 | 9 |

| Flammability rating | UL 94 | / | V-0 |

| Thermal conductivity | ISO 22007 | W/(m ·K) | / |

| Electrical properties | |||

| Dielectric strength | IEC 60243-1 | KV/mm | / |

| Dielectric constant | IEC 60250 | – | / |

| Surface resistance | IEC 61340 | Oh | / |

| Lossy dielectric | IEC 60251 | – | / |

| Other performance | |||

| color | – | black | |

| Actual density | ISO 1183 | g/cm 3 | 1.42 |

| Water absorption rate (25℃.24Hrs) | ISO 62 | % | 0.3 |

| Molding shrinkage (25-24℃) | 3mm thickness, 170°C flow direction |

% | / |

| Perpendicular to the flow direction | % | / | |

| Poisson’s ratio | ISO 527-2 | / | |

| Rockwell hardness | GB/T 3398.2 | HRR | 69 |

| Friction coefficient | ASTM D3702 | m | 0.1-0.2 |

| Limit Lpv value | ASTM D3702 | MPa m/s | 10-18 |

1. Typical values are injection molding specifications. Please contact our technical department for more detailed specifications if necessary.

2. These performance indicators cannot be used as material acceptance criteria.

Contact Us

About Us

Junhua was founded in 2007 and specializes in the development, production, and sale of high-performance engineering plastics, particularly PEEK, PI, PPSU, and other special polymers. The company has a modern factory occupying 15,000+ square meters , with 40+ extrusion lines ,Complete injection molding and CNC processing equipment, with an annual production capacity of over.

We have obtained multiple international certifications such as AS9100D (Aerospace), ISO9001, IATF1649 (Automotive), ISO13485 (Medical Devices), FDA, RoHS, REACH, SGS , and our products are fully traceable . Our customers cover multiple high-threshold industries in over 60 countries and regions , including aerospace, medical, semiconductor, electronics, food, and new energy vehicles. We are committed to becoming a global leader in PEEK solutions.

12 Patents for Invention

27 Utility Model Patents

15,000+㎡ Factory

40+ Extrusion Lines + Cleanroom

60+ Countries

30000+ Global Customers | 300 Million+ RMB Sales

500+ Team Members

18+ Years of Experience | 40+ Global Employees

Multiple International Certifications

AS9100D / ISO13485 / IATF16949 etc.

1000+ Global Partners

Serve 60+ Countries