PEEK with 20% PTFE (PEEK5600FE20) Granules

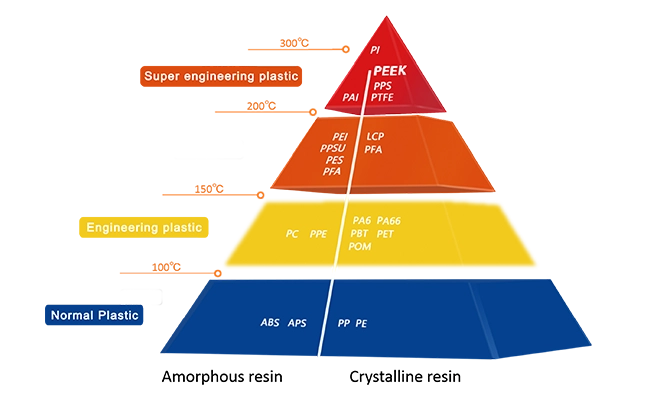

As an advanced engineering plastic, PEEK plays an important role in weight reduction, effectively extending the service life of components, and optimizing component utilization due to its good machinability, flame retardant, non-toxic, wear resistance, corrosion resistance, etc., and the promotion of downstream applications is accelerating. PEEK5600FE20 particles are modified and synthesized PEEK5600G 20% tetrafluorine is developed to meet the needs of high-wear-resistant production environments, and is suitable for injection molding and extrusion production.

It excels in high-temperature dry friction conditions and is a leader in self-lubricating wear resistant materials, PEEK5600FE20. Compared with pure PEEK, it has a lower coefficient of friction, better self-lubricating properties, lower hardness and better wear resistance than PEEK, and has twice the service life of pure PEEK, making it an ideal alternative to PTFE with poor creep resistance. PEEK5600FE20 widely used in the petrochemical industry where high temperature, high humidity and corrosive environments are required, providing reliable protection and long-term stability for equipment.

Contact Us

What is PEEK?

PEEK and its modified composite materials show excellent performance under high temperature and high humidity conditions. PEEK have excellent chemical corrosion resistance, self-lubricating, and wear-resistant properties, so it has become the most ideal material to replace copper alloys and ordinary rubber. Compared with them, PEEK has longer service life which can reduce equipment operating costs, improve equipment operating reliability.

High Temperature Performance

PEEK’s performance can remain stable in the temperature range from -196°C to 260°C. Under extreme working conditions, it can withstand 300″C for a short time. The performance of PEEK is still reliable even in high temperatures of several kilometers underground work environment.

High Strength and Wear Resistance

Compared with other plastics, PEEK is resistant to compression, impact and also have good fatigue resistance. PEEK is durable in mechanical equipment and wear-resistant environments.

Double the Service Life

PEEK sealing solutions can improve the part service life. Some domestic chemical companies use the PEEK5600FE20 polytetrafluoroethylene modified material designed by Junhua to replace the original material, the service life of the wear parts can even be extended by 1.3-3 times.

Corrosion Resistance

PEEK is chemically inert, and has no reaction to most acids, oils, greases and all other organic and inorganic solvents or enzymes, and can still maintain good strength and dimensional stability.

Self-lubricating

PEEK has low friction coefficient, low running resistance, can be used without oil in some working conditions. The equipment is cleaner, thus improving process reliability, improving energy efficiency and saving costs.

More dom in Design

Injection molds can be used for rapid injection molding of large quantities of complex special-shaped parts, and the cost is low compared to machining.