PEEK Rod (PEEK5600LF30)PEEK with 30% Carbon Fiber, Graphite & PTFE (PEEK5600LF30) Rod

PEEK is the result of carbon fiber, graphite and PTFE modification to make PEEK5600LF30 a bearing-grade plastic and is the modified PEEK material with the lowest coefficient of friction, and its superior frictional properties (low coefficient of friction, wear resistance, high peak pressure limit) make it an ideal material for friction applications such as wear strips, friction plates and slides of this class. It is comfortable in dry, wet and oil-lubricated conditions, and performs well even in high sliding speeds and low to medium load environments.

- Ultra-low coefficient of friction: lower than other modified PEEK, providing smoother sliding performance.

- Excellent wear resistance: Maintains excellent wear resistance performance under various working conditions.

- High impact resistance: better impact resistance, suitable for high loads and harsh working environments.

- High Rigidity: Perform well in high-load applications, maintaining stability.

PEEK5600LF30 not only excels in high sliding speeds and low to medium load environments, but also has excellent wear and impact resistance, making it ideal for high-load and harsh working environments.

PEEK extrusion production line

PEEK bar: diameter 3~300mm × 1000/3000mm (length can be customized according to requirements) (if it is not suitable for the above specifications, our company can supply product size, length and width specifications can be cut into pieces).

Junhua Article 2 The continuous extrusion production line of PEEK bar imported from Europe enters the factory, which is more stable and has higher production efficiency, which is suitable for the large-scale continuous and stable production of PEEK bar, helping Junhua improve delivery time and reduce production costs.

| Material | Diameter | Length(mm) | Color |

|---|---|---|---|

| PEEK5600G | 3~300 | 1000, 3000 | Natural, Black |

| PEEK5600CF30 | 5~180 | 1000, 3000 | Black |

| PEEK5600LF30 | 5~180 | 1000, 3000 | Black |

| PEEK5600GF30 | 5~260 | 1000, 3000 | Natural/Black |

| ESD PEEK | 5~260 | 1000, 3000 | Black |

Higher productivity

Comprehensively improve the production efficiency of PEEK bars, which can be increased to 300-400% of the original level, to achieve the goal of ensuring the delivery time of customer orders and improving customer satisfaction.

More consistent quality

Automated production greatly reduces the impact of other factors on production, and the mass production of PEEK bars is stable and reliable, and the color, appearance and internal quality are more advantageous in domestic and foreign markets.

Lower losses and production costs

The new equipment systematically saves production time, manpower and maintenance costs, improves every link of the original production process, and can achieve lower losses and production costs.

Junhua has been expanding the manufacturing capacity of PEEK products, introducing advanced production lines and technologies, and promoting the optimization of PEEK production lines in factories. Junhua will provide you with better and more cost-effective PEEK products and better product solutions with more advanced R&D technology and processing capabilities, and jointly promote PEEK to a broader and better future!

Contact Us

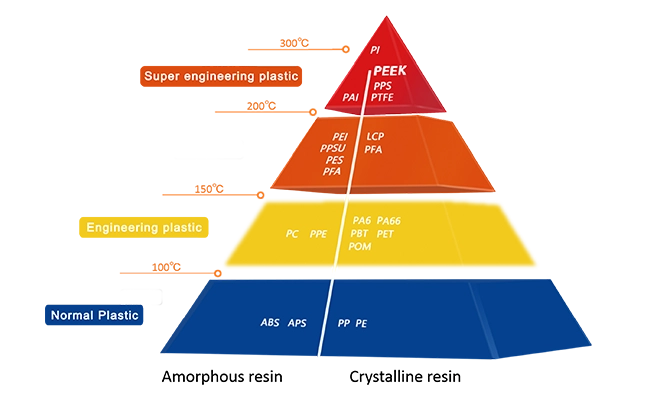

What is PEEK?

PEEK and its modified composite materials show excellent performance under high temperature and high humidity conditions. PEEK have excellent chemical corrosion resistance, self-lubricating, and wear-resistant properties, so it has become the most ideal material to replace copper alloys and ordinary rubber. Compared with them, PEEK has longer service life which can reduce equipment operating costs, improve equipment operating reliability.

High Temperature Performance

PEEK’s performance can remain stable in the temperature range from -196°C to 260°C. Under extreme working conditions, it can withstand 300″C for a short time. The performance of PEEK is still reliable even in high temperatures of several kilometers underground work environment.

High Strength and Wear Resistance

Compared with other plastics, PEEK is resistant to compression, impact and also have good fatigue resistance. PEEK is durable in mechanical equipment and wear-resistant environments.

Double the Service Life

PEEK sealing solutions can improve the part service life. Some domestic chemical companies use the PEEK5600FE20 polytetrafluoroethylene modified material designed by Junhua to replace the original material, the service life of the wear parts can even be extended by 1.3-3 times.

Corrosion Resistance

PEEK is chemically inert, and has no reaction to most acids, oils, greases and all other organic and inorganic solvents or enzymes, and can still maintain good strength and dimensional stability.

Self-lubricating

PEEK has low friction coefficient, low running resistance, can be used without oil in some working conditions. The equipment is cleaner, thus improving process reliability, improving energy efficiency and saving costs.

More dom in Design

Injection molds can be used for rapid injection molding of large quantities of complex special-shaped parts, and the cost is low compared to machining.

PEEK Solutions

Common PEEK Grades and Properties

1. PEEK5600G (brown-gray/khaki) is made from pure polyetheretherketone resin and offers the best toughness and impact resistance of all PEEK grades. Pure PEEK can be sterilized using convenient methods (steam, dry heat, ethanol, and gamma-rays), and the raw materials used in its manufacture comply with EU and US FDA food compatibility regulations. These characteristics make it widely used in the medical, pharmaceutical, and food processing industries.

2. PEEK5600LF30 (black) The addition of PTFE, graphite, and carbon fiber makes PEEK5600LF30 a bearing-grade plastic. Its superior tribological properties (low coefficient of friction, wear resistance, and high peak pressure limit) make it an ideal material for this class of friction applications.

3. PEEK5600GF30 (Brown-Gray): This material is a reinforced grade of plastic filled with 30% glass fiber. It offers superior rigidity, creep resistance, and dimensional stability compared to PEEK, making it ideal for structural parts. It can withstand fixed loads for extended periods at high temperatures. If PEEK5600GF30 is used as a sliding component, its suitability should be carefully verified, as the glass fiber can scratch mating surfaces.

4. PEEK5600CF30 (Black): This material is reinforced with 30% carbon fiber. It offers superior mechanical properties (higher elastic modulus, mechanical strength, and creep resistance) and wear resistance compared to PEEK5600GF30. Furthermore, carbon fiber-reinforced plastic has 3.5 times the thermal conductivity of unreinforced PEEK, dissipating heat more quickly from the bearing surface.

Mechanical Properties

| Item | Test Standard or Instrument |

Unit | PEEK5600G 100% PEEK |

PEEK5600GF30 PEEK+30% glass fiber |

PEEK5600CF30 PEEK+30% carbon fiber |

PEEK5600LF30 PEEK+30% (carbon fiber +graphite+PTFE) |

PEEK5600FE20 PEEK+20%PTFE |

|---|---|---|---|---|---|---|---|

| Tensile Strength (23℃) | ISO 527 | MPa | 95 | 175 | 250 | 145 | 70 |

| Tensile Modulus (23℃) | ISO 527 | GPa | 3.8 | 11 | 23 | 12.5 | / |

| Elongation at Break (23℃) | ISO 527 | % | 35 | 2.0 | 1.5 | 2.2 | / |

| Flexural Strength (23℃) | ISO 178 | MPa | 155 | 235 | 350 | 220 | 118 |

| Flexural Modulus (23℃) | ISO 178 | GPa | 3.5 | 10 | 21 | 11 | / |

| Charpy Impact Strength (unnotched) | ISO 179/1U | kJ/m2 | No break | 55 | 45 | 32 | No break |

| Cantilever Beam Impact Strength (notched) | ISO 180/A | kJ/m2 | 4 | 6 | 6.5 | 4 | 6 |

Thermal Properties

| Item | Test Standard or Instrument |

Unit | PEEK5600G 100% PEEK |

PEEK5600GF30 PEEK+30% glass fiber |

PEEK5600CF30 PEEK+30% carbon fiber |

PEEK5600LF30 PEEK+30% (carbon fiber +graphite+PTFE) |

PEEK5600FE20 PEEK+20%PTFE |

|---|---|---|---|---|---|---|---|

| Melting Point | ISO11357 | ℃ | 343 | 343 | 343 | 343 | 343 |

| Glass Transition Temperature | ISO11357 | ℃ | 143 | 143 | 143 | 143 | 150 |

| Heat Deflection Temperature | ISO 75A/B | 1.8MPa. ℃ | 152 | 315 | 315 | 293 | 150 |

| Thermal Expansion Coefficient | ASTM D696 | ppm K-1 | 45 | 22 | 15 | 22 | 70 |

| Thermal Conductivity | ISO /CD22007-4 | W/(m·K) | 0.29 | 0.32 | 0.95 | 0.86 | / |

Electrical Properties

| Item | Test Standard or Instrument |

Unit | PEEK5600G 100% PEEK |

PEEK5600GF30 PEEK+30% glass fiber |

PEEK5600CF30 PEEK+30% carbon fiber |

PEEK5600LF30 PEEK+30% (carbon fiber +graphite+PTFE) |

PEEK5600FE20 PEEK+20%PTFE |

|---|---|---|---|---|---|---|---|

| Dielectric Strength (2mm) | IEC 60243-1 | kV/mm | 20 | 19 | / | / | 19 |

| Dielectric Constant | IEC 62631 | – | 3.0 | 3.3 | / | / | 2.7 |

| Surface Resistivity | GB/T31838.3 | Ω | 1015 | 1014 | / | / | 1015 |

| Volume Resistivity | IEC 62631 | Ω·cm | 1015 | 1015 | 105 | 106 | / |

Other Properties

| Item | Test Standard or Instrument |

Unit | PEEK5600G 100% PEEK |

PEEK5600GF30 PEEK+30% glass fiber |

PEEK5600CF30 PEEK+30% carbon fiber |

PEEK5600LF30 PEEK+carbon fiber +graphite+PTFE |

PEEK5600FE20 PEEK+20%PTFE |

|---|---|---|---|---|---|---|---|

| Color | / | / | Natural | Natural | Black | Black | Natural |

| Melt Flow Index (400℃, 2.16kg) | ISO 1133 | g/10min | 6-10 | 2-5 | 1-3 | 2-5 | / |

| Density | ISO 1183 | g/cm3 | 1.30±0.02 | 1.50±0.02 | 1.40±0.02 | 1.44±0.02 | 1.41±0.02 |

| Water Absorption (23℃, 24Hrs) | ISO 62-1 | % | 0.07 | 0.05 | 0.04 | 0.05 | 0.15 |

| Rockwell Hardness | / | HRR | 118 | 119 | 121 | 108 | 113 |

| Flammability Rating | UL 94 | / | V-0 | V-0 | V-0 | V-0 | / |

| Coefficient of Friction | ASTM D3702 | 100N-120rpm | 0.30-0.38 | 0.38-0.46 | 0.15-0.25 | 0.18-0.30 | 0.1-0.2 |

*This data is for reference and not a guarantee. For a more detailed data sheet, please contact our company’s technical department.