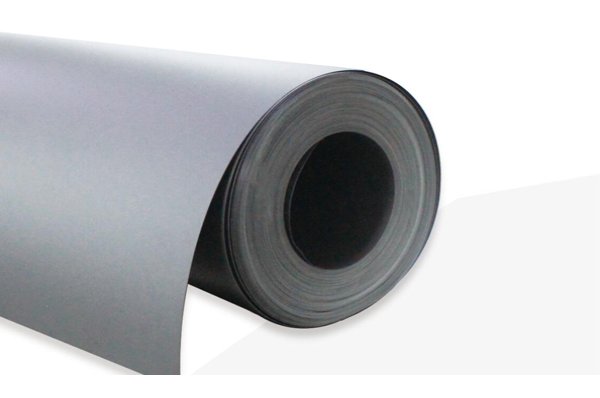

PEEK films/sheets are made by melting PEEK particles at high temperature and then casting them into a tape-cast form. The films we produce are mainly divided into amorphous transparent films and crystalline films.

PEEK Material Applications

Electronic Products

- • CD/DVD drive components

- • Printer components

- • Chip carriers

- • Smartphone insulation components

- • Camera components

Automotive

- • Brake systems

- • Clutches

- • Transmission parts

- • Drive system components

- • Automotive exhaust components

Oil & Gas, Petrochemical

- • Lifting pumps

- • Pump bodies, valves

- • Valve gaskets

- • Wear rings, wear strips

- • Seals

- • Reciprocating compressor components

Aerospace

- • Aircraft components

- • Aerospace structural parts

- • Airframe wear sleeves

- • Thrusters, actuators

Electronics, Semiconductors

- • Wafer dicing trays

- • Ion implant components

- • Etching equipment components

- • Wafer handling components

Food and Medical

- • Implants

- • Dentures

- • Sterilizers

- • Sterilization containers

- • Orthopedic instruments

- • Surgical instruments

PEEK Film / PEEK Sheet

| Product Name Code | Color | Surface Texture | Thickness × Width {T×W} mm |

|---|---|---|---|

| PEEK Film | Natural/Black | Polished/Unpolished, Gloss/Matte | (0.1~0.25) × 1360 |

| PEEK Sheet | Natural/Black | Polished/Unpolished, Gloss/Matte | (0.25~0.4) × 1360, (0.5~0.8) × 660 |

PEEK — Typical Properties

| Property Group | Property | Test Method | Units | Value |

|---|---|---|---|---|

| Physical | Density | ASTM D792 | g/cm3 | 1.26 – 1.29 |

| Average Water Absorption (24 h) | ASTM D570 | % | 0.04 | |

| Heat Shrinkage (200°C) | ISO 11501 | % | 0.8 – 4.7 | |

| Mechanical | Tensile Strength at Yield (MD) | ASTM D882 | MPa | 70 – 90 |

| Tensile Strength at Yield (TD) | ASTM D882 | MPa | 68 – 86 | |

| Tensile Strength at Break (MD) | ASTM D882 | MPa | 120 – 186 | |

| Tensile Strength at Break (TD) | ASTM D882 | MPa | 112 – 115 | |

| Elongation at Break (MD) | ASTM D882 | % | 186 – 225 | |

| Elongation at Break (TD) | ASTM D882 | % | 145 – 180 | |

| Tensile Modulus (MD) | ASTM D882 | MPa | 1993 – 2755 | |

| Tensile Modulus (TD) | ASTM D882 | MPa | 1964 – 2568 | |

| Thermal | Melting Point | ISO 11357 | °C | 343 |

| Coefficient of Thermal Expansion (< Tg) | ISO 11359 | ppm / K | 55 – 60 | |

| Glass Transition Temperature | ISO 11357 | °C | 153 | |

| Electrical | Dielectric Strength (25 μm) | ASTM D149 | kV/mm | 150 |

| Volume Resistivity @25°C, 50% RH | ASTM D257 | Ω·m | 1016 | |

| Dielectric Constant (50 MHz) | ASTM D150 | — | 3.12 – 3.3 | |

| Loss Tangent (50 MHz) | ASTM D150 | — | 0.004 – 0.005 |

Advantages of PEEK Material

High and Low Temperature Resistance

High temperature resistance, melting point index… The operating temperature is 267°C, and it still maintains… at -196°C.

Wear and Self-Lubricating

Minimal wear loss, with excellent self-lubricating properties.

Superior Insulation Performance

In high temperature, high pressure, humid and other environments, it still has excellent insulation performance…

Corrosion Resistance

In common chemical reagents, it can dissolve or swallow its… organic solvents, known…

Good Radiation Resistance

Has good resistance to various rays.

Good Flame Retardancy

A certain thickness of PEEK…

Hydrolysis Resistance

Has a low water absorption rate (0.04%), and can be used in 200°C steam…

Good Flexibility

Good flexibility