PEEK bushing (JUNHUA-HT4600CF30)

- Overview of JUNHUA-HT4600CF30 large bushing

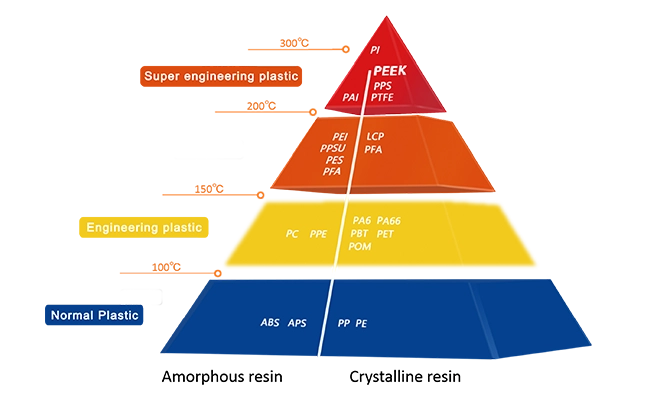

JUNHUA-HT4600CF30 is a high-strength PAEK alloy material, using 30% high-strength carbon fiber combined with excellent performance PAEK polyaryl ether ketone material, the product has the characteristics of high strength, high temperature resistance, low linear expansion coefficient and other characteristics, which can be widely used in aerospace, automotive electronics, petrochemical, instrument analysis and other fields.

PEEK bushing (JUNHUA-HT4600CF30) : The material has good performance, stable dimensions, specifications can be customized, high temperature resistance, wear resistance, and strong mechanical properties. High temperature resistant PEEK has a high glass transition temperature and melting point (373°C), which is one of the reasons why it can be reliably used in applications where heat resistance is required. Its load heat deformation temperature is as high as 365°C, and the continuous service temperature is about 300°C. JUNHUA-HT4600CF30 has the comprehensive performance of other general-purpose plastics in high-performance polymers, and has the performance of various harsh environments, and has been successfully used in various industries such as aerospace, automobile, electronic semiconductor, electromechanical and other industries with more demanding occasions.

The seat can operate without resistance at a high temperature of 300°C, making it suitable for high-temperature environments. Compared with metal seats, it operates without noise, is lightweight, corrosion-resistant, wear-resistant, easy to process, and has excellent insulation and cost-effectiveness, making it particularly suitable for high-temperature, corrosive environments and applications with high weight and noise requirements.

In some industries, including oil and gas, the primary use of PEEK is to provide mechanical support for softer sealing materials.

What is PEEK?

PEEK and its modified composite materials show excellent performance under high temperature and high humidity conditions. PEEK have excellent chemical corrosion resistance, self-lubricating, and wear-resistant properties, so it has become the most ideal material to replace copper alloys and ordinary rubber. Compared with them, PEEK has longer service life which can reduce equipment operating costs, improve equipment operating reliability.

High Temperature Performance

PEEK’s performance can remain stable in the temperature range from -196°C to 260°C. Under extreme working conditions, it can withstand 300″C for a short time. The performance of PEEK is still reliable even in high temperatures of several kilometers underground work environment.

High Strength and Wear Resistance

Compared with other plastics, PEEK is resistant to compression, impact and also have good fatigue resistance. PEEK is durable in mechanical equipment and wear-resistant environments.

Double the Service Life

PEEK sealing solutions can improve the part service life. Some domestic chemical companies use the PEEK5600FE20 polytetrafluoroethylene modified material designed by Junhua to replace the original material, the service life of the wear parts can even be extended by 1.3-3 times.

Corrosion Resistance

PEEK is chemically inert, and has no reaction to most acids, oils, greases and all other organic and inorganic solvents or enzymes, and can still maintain good strength and dimensional stability.

Self-lubricating

PEEK has low friction coefficient, low running resistance, can be used without oil in some working conditions. The equipment is cleaner, thus improving process reliability, improving energy efficiency and saving costs.

More dom in Design

Injection molds can be used for rapid injection molding of large quantities of complex special-shaped parts, and the cost is low compared to machining.

Contact Us

Service

Junhua offers one-stop PEEK solutions from design to after-sales, ensuring quality, innovation, and customer satisfaction.

Design and processing

Junhua offers injection molding, machining, and extrusion solutions to optimize design and cost.

Material selection

Junhua specializes in PEEK with multiple grades and recommends the best engineering plastics for your needs.

Measurement

Junhua uses high-precision instruments to provide customers with accurate drawings.

Sampling

Junhua supplies samples for testing and refines designs until approval for mass production.

Mass Production

Junhua controls raw materials, processes, and inspections to ensure consistent product quality.

Quality Control

Junhua follows ISO9001 standards and provides full inspection reports as required.

Improve

Junhua continuously optimizes designs and processes through improvement systems and case experience.

After-sales Service

Junhua offers complete after-sales support to resolve technical issues and protect customer interests.