Anti-static PEEK(PEEK5600ESD) Sheet

Antistatic PEEK sheets excel in antistatic properties, ease of processing, and aesthetics. They are widely used in the electronics, semiconductor, and petroleum industries, effectively reducing damage caused by static electricity. Furthermore, antistatic PEEK5600ESD is also used in the housings and structural components of explosion-proof products, such as electrical appliances used in coal mines, tankers, and oil fields, demonstrating broad application prospects and enormous market potential.

We offer nearly 100 extrusion dies in a wide range of diameters and specifications, with a full range of specifications available year-round. Anti-static PEEK sheet is UL-certified for high-temperature operation at a temperature of 260°C. Even at temperatures as high as 300°C, it maintains excellent mechanical properties. This material excels in anti-static properties, ease of processing, and appearance, making it widely used in the electronics, semiconductor, and petroleum industries, effectively reducing losses caused by static electricity. Furthermore, this anti-static PEEK5600ESD is also used in the housings and structural components of explosion-proof products, such as electrical appliances used in coal mines, oil tankers, and oil fields, demonstrating broad application prospects and enormous market potential.

| Performance | Test standards | unit | PEEK | PEEK5600ESD | Conductive PEEK | |

| Physical properties | ||||||

| density | ISO 1183 | g/cm³ | 1.32 | 1.41 | 1.43 | |

| Water absorption | ISO 62 | % | 0.4 | 0.2 | 0.4 | |

| Mechanical properties | ||||||

| Yield tensile strength | ISO 527 | Mpa | 91 | 110 | 100 | |

| Elongation at break | ISO 527 | % | 11 | 20 | 20 | |

| elastic modulus | ISO 527 | Mpa | 4210 | 3800 | 3800 | |

| Notched impact strength | ISO 179 | KJ/M 2 | 4 | 8.2 | 7.3 | |

| hardness | ISO 868 | Shore D | 90 | 88 | 87 | |

| Thermal performance | ||||||

| Melting point | DIN EN ISO 3146 | ℃ | 340 | 343 | 343 | |

| Thermal conductivity | ISO 22007-4 | W/(m*K) | 0.25 | 0.25 | 0.25 | |

| Heat capacity | DIN52612 | KJ/(kg*K) | 1.34 | 1.34 | 1.34 | |

| Linear thermal expansion coefficient | ISO 11359 | K-1 10-4 | 0.47 | 50 | 50 | |

| Long-term operating temperature | – | ℃ | -40 …260 | -40 …260 | -40 …260 | |

| Operating temperature (instantaneous) | – | ℃ | 310 | 310 | 310 | |

| Heat deformation temperature | ISO 75 | ℃ | 158 | 152 | 152 | |

| Electrical properties | ||||||

| Surface resistance | IEC 60093 | ohms | 1013 | 106-9 | 103-5 | |

| Volume resistivity | IEC 60093 | ohms.cm | 1013 | 106-9 | 103-5 | |

| Dielectric constant | IEC 60250 | 3.2 | 3.2 | 3.2 | ||

| Dielectric loss | DIN53483 | 0.025 | 0.003 | 0.003 | ||

| Dielectric strength | IEC 60243-1 | In | 16 | 19 | 19 | |

| other | ||||||

| Combustion performance | UL94 | |||||

PEEK Continuously Extruded Sheet

Features and Benefits: High-temperature resistance, wear resistance, corrosion resistance, high strength, easy processing, flame retardant, low smoke, and non-toxic.

Product Trends in the Industry: Using lightweight PEEK thermoplastic, it meets environmental requirements, enabling faster assembly, higher reliability, and lower operating and manufacturing costs.

Compared to sheets produced using traditional hot molding processes, PEEK continuously extruded sheet exhibits significantly better thickness uniformity and higher internal density, making it widely used as a material for CNC machining and other applications.

PEEK Continuous Extrusion Sheet Production Line

Junhua has introduced an advanced European PEEK profile extrusion line, capable of producing large-format PEEK sheets up to 1250mm wide. This significantly improves production efficiency, enhances PEEK product quality, ensures delivery time, and reduces costs. Currently, PEEK sheet extrusion production in China is generally limited. The new equipment imported from Europe and the United States has significantly increased the company’s production capacity while improving sheet quality, effectively meeting customer delivery requirements.

This line can extrude PEEK sheet up to 1250mm wide, expanding Junhua’s sheet width from 600mm to 1250mm, expanding the market and meeting customer demand for extra-wide PEEK sheet. The 1250mm PEEK sheet meets the demand for large-sized PEEK parts in industries such as valves. Furthermore, the wider sheet offers higher material utilization when processed on typesetting and cutting machines.

This continuous PEEK sheet extrusion line produces PEEK square sheets and sheets in a variety of specifications, capable of producing PEEK sheet up to 1250mm wide.

| Material | width | thickness | length | color |

| PEEK5600G | 600~1250 | 5-100 | 1000、3000 | Natural color, black |

| PEEK5600CF30 | 600 | 6~60 | 1000、3000 | black |

| PEEK5600LF30 | 600 | 6~60 | 1000、3000 | black |

| PEEK5600GF30 | 600 | 5~60 | 1000、3000 | Natural color, black |

| PEEK5600ESD | 600 | 6~60 | 1000 | black |

| CF/PEEK | 600/1000 | 2~50 | 1000、3000 | black |

Contact Us

PEEK Solutions

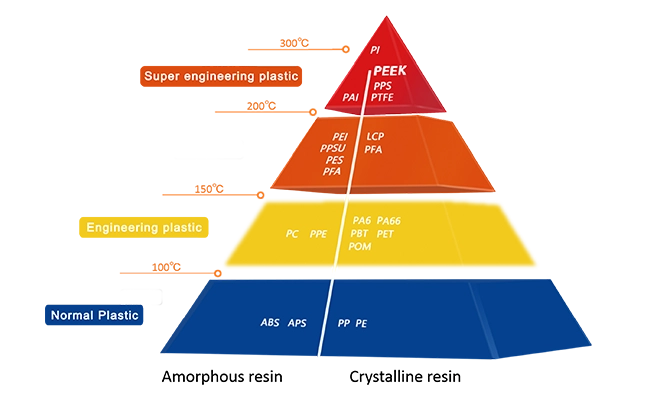

What is PEEK?

PEEK and its modified composite materials show excellent performance under high temperature and high humidity conditions. PEEK have excellent chemical corrosion resistance, self-lubricating, and wear-resistant properties, so it has become the most ideal material to replace copper alloys and ordinary rubber. Compared with them, PEEK has longer service life which can reduce equipment operating costs, improve equipment operating reliability.

High Temperature Performance

PEEK’s performance can remain stable in the temperature range from -196°C to 260°C. Under extreme working conditions, it can withstand 300″C for a short time. The performance of PEEK is still reliable even in high temperatures of several kilometers underground work environment.

High Strength and Wear Resistance

Compared with other plastics, PEEK is resistant to compression, impact and also have good fatigue resistance. PEEK is durable in mechanical equipment and wear-resistant environments.

Double the Service Life

PEEK sealing solutions can improve the part service life. Some domestic chemical companies use the PEEK5600FE20 polytetrafluoroethylene modified material designed by Junhua to replace the original material, the service life of the wear parts can even be extended by 1.3-3 times.

Corrosion Resistance

PEEK is chemically inert, and has no reaction to most acids, oils, greases and all other organic and inorganic solvents or enzymes, and can still maintain good strength and dimensional stability.

Self-lubricating

PEEK has low friction coefficient, low running resistance, can be used without oil in some working conditions. The equipment is cleaner, thus improving process reliability, improving energy efficiency and saving costs.

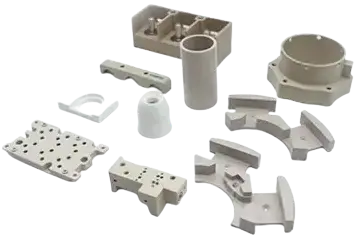

More dom in Design

Injection molds can be used for rapid injection molding of large quantities of complex special-shaped parts, and the cost is low compared to machining.