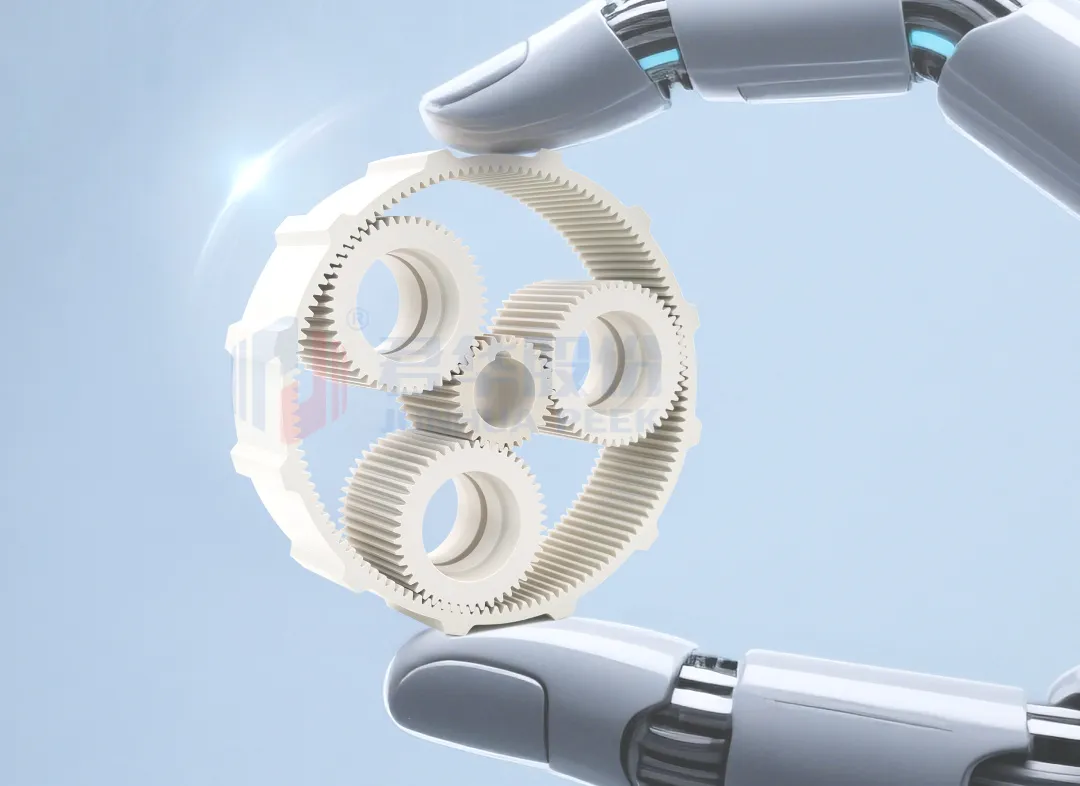

In the era of rapid advancements in robotics, achieving longer operational endurance and lightweight designs has become a critical challenge. As the core drive unit of precision robots such as dexterous hands, the combination of coreless cup motors and PEEK gears represents a “powerful synergy.” This pairing not only significantly reduces system weight but also enhances energy efficiency, effectively addressing current technological bottlenecks and helping humanoid robots “grasp the future.”

PEEK Gears: The Ideal Match for High-Performance Coreless Cup Motors

PEEK gears offer core advantages such as extreme lightweight, self-lubrication, low-noise operation, and exceptional wear resistance. These characteristics align perfectly with coreless cup motors’ requirements for low inertia, high responsiveness, and high efficiency. Their application can dramatically improve the performance of robotic joint modules, making them an ideal choice for high-end precision robotic transmission systems.

Specifically, PEEK gears bring the following key benefits to coreless cup motors:

1. Ultra-Lightweight for Faster Response

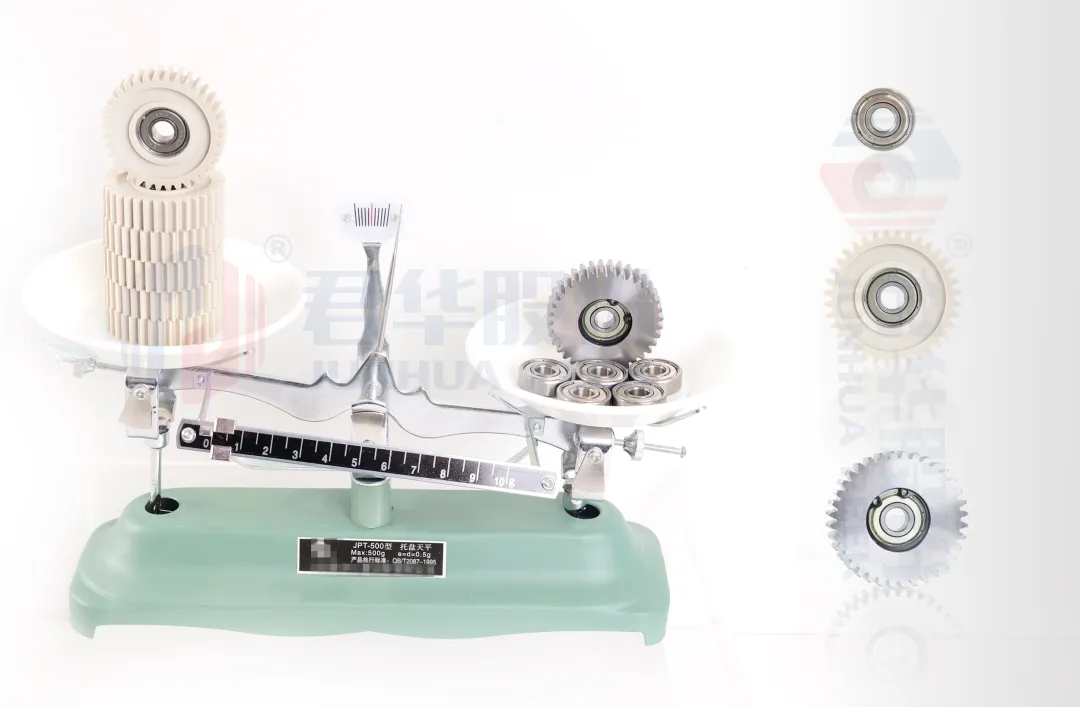

With a density of only 1.3 g/cm³—far lower than steel (7.8 g/cm³) and brass (8.4 g/cm³)—PEEK gears drastically reduce rotational inertia in the drive system. This allows motors to start, stop, and reverse direction within milliseconds while minimizing energy lost to inertia. Heavy metal gears, in contrast, increase rotor load inertia, slowing response and consuming more energy during acceleration and deceleration.

2. Enhanced Energy Efficiency for Longer Endurance

Lower rotational inertia directly reduces wasted energy, allowing more power to be utilized for effective output. This improves the overall energy efficiency of the system and extends the operational endurance of robots.

3. Self-Lubricating and Wear-Resistant for Easier Maintenance

PEEK features a low friction coefficient and excellent wear resistance, enabling self-lubricating operation without additional lubrication. This avoids potential contamination, drying, and dust accumulation from oils and is particularly suitable for medical, laboratory, food processing, and vacuum environments that require high cleanliness standards.

4. Low-Noise, Smooth Operation

When meshed with metal gears, PEEK gears reduce friction and vibration, delivering quieter and smoother performance. The material’s inherent damping properties absorb shocks and vibrations during motion, enhancing control stability and precision.

5. High Strength and Durability for High-Speed Applications

PEEK maintains lightweight advantages while offering mechanical strength, stiffness, and fatigue resistance close to metals, meeting the high rotational speed demands of coreless cup motors (tens of thousands of RPM) and ensuring long-term reliability.

6. Outstanding Chemical Resistance and Environmental Adaptability

PEEK resists most chemicals, solvents, and humid conditions, making it ideal for medical environments that require frequent disinfection or industrial settings exposed to chemical reagents, avoiding the corrosion issues commonly seen with metal gears.

7. Excellent Electrical Insulation for Enhanced Safety

As an electrical insulator, PEEK gears provide additional electrical isolation for the drive system, simplifying insulation design and improving overall system safety.

The combination of coreless cup motors and PEEK gears offers high-speed, low-inertia, and highly responsive performance, precisely matching the “fast and precise” motion requirements of dexterous hands. PEEK gears are emerging as a key technology and material choice driving the next generation of high-performance robotic components.

Junhua: Professional PEEK Solutions Provider

As a leading PEEK material supplier, Junhua possesses a complete industrial chain capability. From material selection to design, our professional team provides comprehensive technical support, including product modeling, precision injection molding, and machining. We are committed to delivering professional PEEK application solutions, fully aligned with customer needs to ensure optimal product performance.