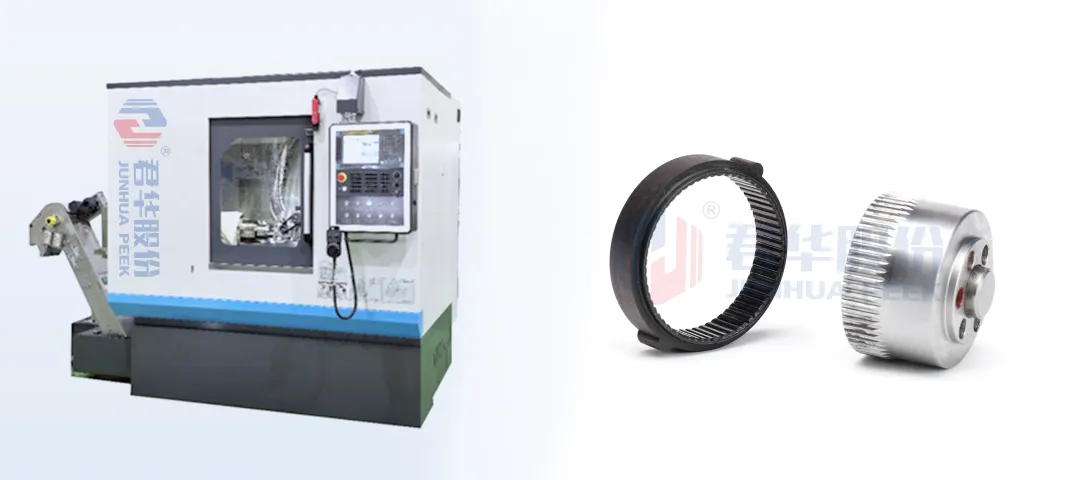

The harmonic drive is a brilliant mechanical innovation—a precision device capable of converting high-speed, low-torque input into low-speed, high-torque output. A harmonic drive is composed of three major components:

- The Circular Spline (left): a rigid ring with internal teeth

- The Flexspline (center): a thin-walled, flexible gear with external teeth, typically two teeth fewer than the circular spline

- The Wave Generator (right): an elliptical component equipped with ball bearings

But how does it function inside humanoid robot joints? What technological barriers define its performance?

How the Harmonic Drive Works

When the wave generator is inserted into the flexspline, it deforms the flexspline into an elliptical shape. This causes the flexspline’s external teeth to engage with the circular spline’s internal teeth at both ends of the ellipse’s major axis, while disengaging along the minor axis.

As the wave generator rotates, it forces the flexspline to undergo periodic radial deformation.

Since the flexspline has two fewer teeth than the circular spline:

- When the wave generator rotates 180° clockwise, the flexspline moves one tooth counterclockwise relative to the circular spline

- When the wave generator completes one full rotation, the flexspline moves two teeth

This fundamental tooth difference produces a high reduction ratio and torque amplification.

Because the harmonic drive is extremely compact, it has become widely used in humanoid robot joints.

Core Technical Barriers

1. Flexspline Material & Fatigue Resistance

The flexspline undergoes frequent elastic deformation at microscopic scales. This requires materials with:

- Extremely high elastic limits

- Outstanding fatigue resistance

- Precisely controlled purity levels

Special steels must be used, with precisely controlled heat-treatment time and temperature, to achieve the required toughness and strength.

2. Circular Spline Rigidity & Wear Resistance

During engagement, the circular spline must remain essentially undeformed so that all deformation introduced by the wave generator is transferred to the flexspline. This requires materials with:

- High rigidity

- Excellent wear resistance

3. Advantages of PEEK5600CF30

PEEK5600CF30 offers:

- High modulus

- Low friction

- Low wear rate

Circular splines made from PEEK5600CF30, when paired with steel flexsplines, can maintain transmission precision while offering:

- Significant weight reduction

- Improved wear resistance

- Reduced operating noise

In humanoid robot applications, harmonic drive assemblies made from PEEK can achieve:

- Up to 40% weight reduction

- Up to 20% space savings

Weight reduction increases the robot’s payload capacity and extends battery life.

4. Gear Tooth Profile: Precision Determines Performance

Tooth profile design governs:

- Transmission accuracy

- Service life

- Rigidity

- Efficiency

A well-designed profile ensures continuous, smooth, zero-backlash engagement, minimizing transmission error.

5. High-Precision Manufacturing Requirements

Manufacturing the flexspline and wave generator requires micron-level accuracy, relying on:

- High-precision five-axis machining centers

- Gear cutting machines

- Specialized cutting tools

Equipment is expensive, and operators require high technical expertise.

For scalable mass production, manufacturers must ensure:

- Stable material performance

- Reliable machining and assembly processes

- Comprehensive, traceable inspection systems

- Rigorous cost control

Only then can high-precision harmonic drives be produced at low cost and high volume.

Future Outlook

The humanoid robotics industry is experiencing explosive growth as leading companies worldwide accelerate R&D and industrialization. As a core component of robotic joints, harmonic drives are seeing sharply rising demand.

Current Usage in Mainstream Humanoid Robots

- International humanoid robots typically use 14 harmonic drives in 28 rotational actuators

- Domestic humanoid robots generally use 3–6 units

- PEEK-based harmonic drives still have significant room to grow

Forecast for Global Market Demand

According to Dongwu Securities:

- 2025: ~160,000 harmonic drives

- 2026: ~900,000 units

- 2027: ~6,000,000 units

- 2030: Global humanoid robot sales expected to reach 3.5 million units

- With an average of 10 harmonic drives per robot, total market demand will exceed 42 million units

Junhua’s Role in the Future of Humanoid Robotics

As a specialized supplier in the PEEK materials industry, Junhua possesses a fully integrated production chain and is committed to providing PEEK-based application solutions for humanoid robots.

We support customers through the entire development process—enabling lightweight, high-performance components and cost-efficient mass production for the next generation of humanoid robots.