On May 28, 2025, the 10th Special Engineering Plastics Industry Forum was successfully held in Shanghai. As a leading event in the field, the forum focused on cutting-edge technologies and application development for high-performance materials such as Polyether Ether Ketone (PEEK) and Polyphenylene Sulfide (PPS). Junhua was honored to be invited to the forum, where its high-performance PEEK products and pioneering semiconductor applications became a highlight of the event.

In-Depth Presentation: Exploring the Value of PEEK in Semiconductor Applications

At the forum, Junhua delivered a keynote titled “High-Performance PEEK Products and Their Applications in the Semiconductor Industry”, offering deep insights into the unique advantages and broad prospects of PEEK in semiconductor manufacturing.

No.1 Understanding PEEK Material

Junhua provided a comprehensive overview of PEEK—a high-performance thermoplastic polymer recognized globally for its exceptional properties, including high-temperature resistance, chemical corrosion resistance, wear resistance, low outgassing, and dimensional stability. By incorporating reinforcements such as carbon fiber (CF) or glass fiber (GF), PEEK’s mechanical properties can be significantly enhanced. These modifications allow PEEK to maintain excellent tensile, flexural, and compressive strength even at elevated temperatures—making it an ideal material for demanding semiconductor applications.

No.2 Practical Applications in Semiconductor Industry

Junhua showcased various real-world applications of PEEK in semiconductor processes. For instance, PEEK is widely used in the manufacturing of CMP (Chemical Mechanical Polishing) retaining rings, plasma etching chamber liners, gas distribution plates, and CVD (Chemical Vapor Deposition) fixtures. Compared to traditional materials, PEEK CMP rings last twice as long and are fully recyclable, significantly reducing downtime and environmental waste. In etching and deposition systems, PEEK’s superior chemical resistance extends part lifespans 3–5 times compared to aluminum, enhancing process stability and yield.

In wafer handling systems, PEEK’s ultra-low outgassing and anti-static properties make it ideal for keycomponentssuch as wafer carriers, vacuum nozzles, robotic end effectors, and non-marking suction cups. These features reduce contamination risk in ultra-clean environments and minimize electrostatic damage to wafers. From 2022 to 2027, the market demand for PEEK in wafer carriers and vacuum pick-upcomponentsis projected to grow from 35.15 tons to 133.70 tons, with a compound annual growth rate of 30.63%.

PEEK also shines in critical areas like wet processes and vacuum systems. It is widely used in the production of valves, pump parts, and tubing that must endure aggressive chemicals. In ultra-high vacuum environments, PEEK’s low outgassing makes it ideal for seals and insulators. Its long service life and recyclability align perfectly with the semiconductor industry’s green transformation goals.

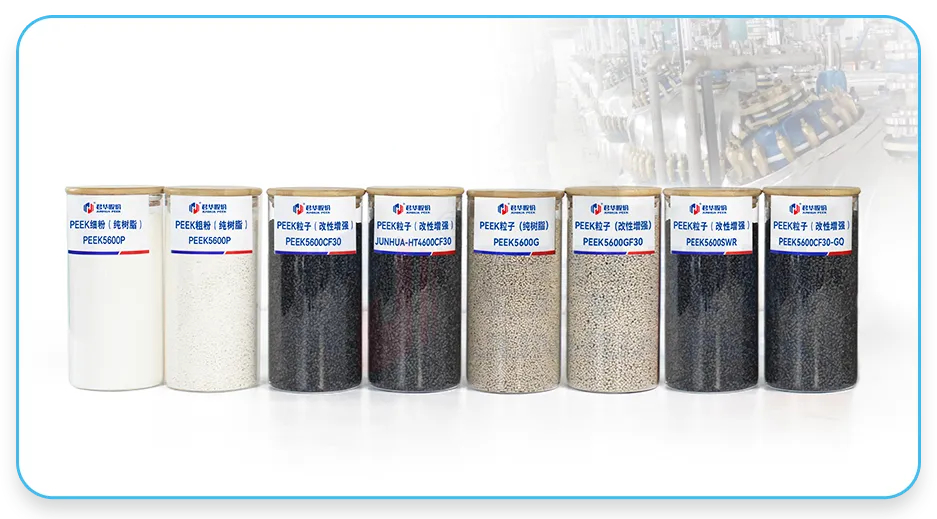

Product Showcase: Demonstrating Technical Strength and Innovation

During the forum, Junhua introduced its wide range of high-performance PEEK product forms, including sheets, rods, tubes, filaments, capillaries, and films—demonstrating its robust capabilities in PEEK material production. Special focus was given to semiconductor-specific solutions such as CMP retaining ring blanks, wafer cleaning equipmentcomponents, vacuum pens, wafer clamps, anti-scratch suction cups, high-temperature rollers, support wires, glass substrate cassettes, PEEK IC sockets, and conductive bearings.

These products, built on PEEK’s high purity, temperature resistance, chemical stability, and low emissions, effectively address the challenges of semiconductor manufacturing by improving production efficiency, yield, and equipment reliability.

Corporate Vision: Leading the Development of Special Engineering Plastics

Since its founding in 2007, Junhua has been committed to the research, development, and production of specialtypolymerssuch as PEEK and PI, evolving into a leading enterprise with fullindustrialchain capabilities. Headquartered in Changzhou, Jiangsu, the company also operates branches in Shanghai, Jining (Shandong), and Germany. With a registered capital of RMB 51 million and over 500 employees, Junhua continues to drive innovation through significant R&D investments.

The company has led or participated in drafting five national standards, two industry standards, and two association standards. It holds 62 invention patents—including methods for preparing benzenoid-terminated polyaryletherketonepolymersand continuous CF/PEEK composites—and 40 utility model patents. In collaboration with top universities such as Jilin University, Junhua has established Shandong Junhao High-Performance Polymer Co., Ltd., including a 2,500-ton annual PEEK polymerization facility to further solidify its technical leadership.

Junhua’s products are widely applied across multiple industries, including electronics and semiconductors, photovoltaics, aerospace, medical devices, analytical instrumentation, petrochemicals,gearsand seals, food processing, new energy vehicles, textiles, and composites. In the semiconductor sector, Junhua has established long-term strategic partnerships with key players, providing critical support for wafer fabrication, handling, and advanced packaging.

Looking Ahead: Building a Sustainable Future with High-Performance Materials

Upholding its core values of integrity, pragmatism, collaboration, innovation, and mutual success, Junhua continues to advance its vision: to become a publicly listed innovation-driven company with full value chain advantages in the field of special engineering plastics. The company is committed to increasing investment in high-performance PEEK R&D, optimizing product capabilities, and expanding application scenarios. By strengthening cooperation across the supply chain, Junhua aims to foster a comprehensiveindustrialecosystem that accelerates the broader adoption of PEEK in the semiconductor industry and beyond.

By participating in the 10th Special Engineering Plastics Industry Forum, Junhua not only showcased its achievements in PEEK materials and semiconductor applications but also strengthened engagement with peers, researchers, and potential partners. As the wave of high-performance materials innovation continues, Junhua is poised to lead the charge—empowering the global high-tech industry with advanced materials and forward-thinking solutions.