PEEK (Polyether Ether Ketone) is a high-performance engineering plastic known for its outstanding resistance to high temperatures, pressure, and chemical corrosion. It is highly regarded in the sealing industry, particularly for applications that require durability in extreme environments. PEEK materials offer a unique advantage when used in sealing rings for such challenging conditions.

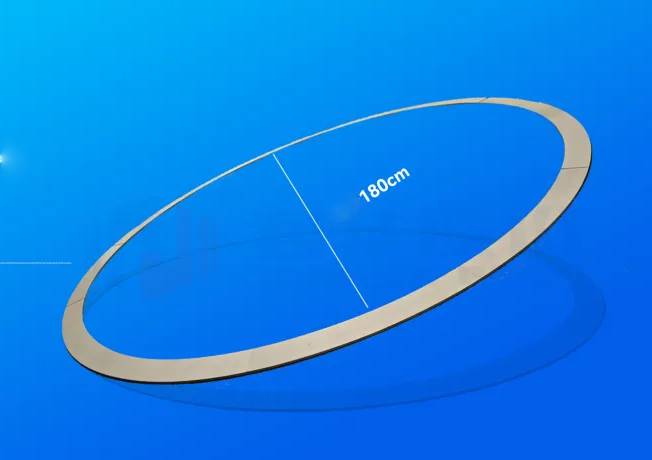

Traditional manufacturing methods for large sealing rings, such as direct injection molding, compression molding, or extrusion, are often costly and inefficient in material usage. To address these issues, we’ve adopted an innovative manufacturing process. This involves designing PEEK sheets, precision milling them into the required curved sections, and then welding these sections together to form a complete ring. This method not only increases material utilization to over 80% but also ensures mechanical performance after welding reaches over 90% of the original material through precise control of temperature, pressure, and time during the welding process, resulting in a high-quality product.

The welding process for PEEK involves heating the material to a molten state, then applying pressure to bond two surfaces tightly. In this process, new chemical bonds form between the material molecules, achieving a strong, secure connection. This method is particularly well-suited for large PEEK sealing rings, and by adjusting welding parameters, we can achieve optimal welding results. The advantages of this technology include:

- Precision arc welding from meticulously sculpted sheet materials, with a material utilization rate of over 80%.

- Uniform, defect-free welds that prevent media leaks, ensuring stable equipment operation.

- Tensile, bending, and impact strengths that retain up to 90% of the original material properties.

- Fatigue resistance comparable to the original material, reducing replacement and maintenance costs.

Applications:

- Chemical Industry: PEEK sealing rings withstand corrosion, high temperatures, and high-pressure conditions typical in chemical processing, ensuring a safe and stable production environment. For example, in sulfuric acid production, PEEK rings resist corrosion from concentrated sulfuric acid and the high-pressure, high-temperature conditions within the reactors.

- Petroleum Industry: In oil extraction and refining, PEEK sealing rings function reliably in the presence of complex chemical compositions, high temperatures, and high-pressure environments, preventing leaks and safeguarding the environment while ensuring smooth equipment operation.

- Power Generation: In thermal power plants, PEEK sealing rings perform well under high-temperature conditions in steam pipelines and turbines, meeting the sealing requirements of steam pipes and enhancing both safety and efficiency.

Due to its outstanding performance in sealing applications, PEEK has become essential in industries such as chemical processing, petroleum, and power generation. As technology advances, the application of PEEK sealing rings will continue to expand, offering high-performance sealing solutions across an even broader range of industries.