PEEK Seal

PEEK Seal

PEEK Seal

Jiangsu Junhua Special Plastics has cooperated with Saudi Arabia, PetroChina, Sinopec,

University of Petroleum, Xi'an and other customers to produce PEEK support sealing ring,

PEEK front and rear plugs, PEEK insulating ring, PEEK polar plate, PEEK insulating wire,

PEEK spacer ring, PEEK retaining ring, PEEK Wear-resistant shaft sleeves and other

products.

High-performance plastic parts such as high-temperature wear-resistant bushings, insulating

rings, and front and rear plugs made of PEEK and its modified composite materials can

replace traditional materials such as copper alloys, stainless steel, PTFE, ordinary

engineering plastics, and graphite. Oil logging and production equipment have strict

technical requirements for parts such as wear resistance, high temperature resistance, high

strength, oil- lubrication, acid-base corrosion, and high reliability, which can reduce

operating costs and help equipment to continuously operate at the highest production

capacity. stable production.

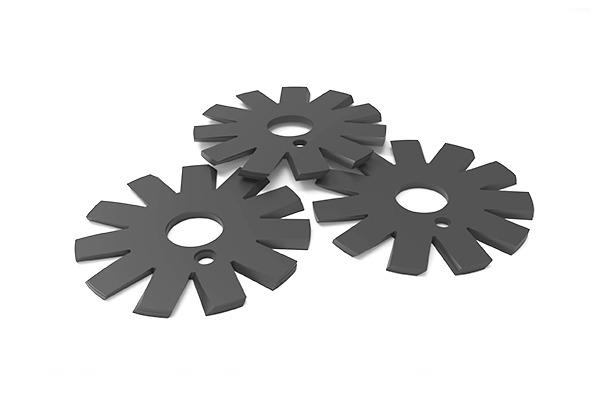

PEEK Gear Application

The PEEK polymer and composite high-performance plastic parts produced by the company have been widely used in various links such as downhole measurement, oil exploration, petrochemical plant production and transportation.

Continuous Carbon Fiber CF/PEEK Composite Pipe

- ◆ 67% longer service life than steel pipe

- ◆ 65% lighter than metal pipes

- ◆ It is more resistant to corrosion by hydrogen sulfide and carbon dioxide than steel pipes

- ◆ Long-term use in methanol and 160℃ environment

- ◆ Smooth corrosion resistance ensures excellent fluidity

- ◆ Replaces corrosion-resistant alloys that are often used in the oil and gas industry to replace those used in piping systems.

PEEK for sealing: a reliable sealing solution

- ◆ In the environment of seawater, hydrocarbons, and 100% hydrogen sulfide gas, the strength retention rate reaches 100% after a high temperature of 175 ° C for 1000 hours

- ◆ Double the pressure resistance of PTFE

- ◆ 300 times higher creep resistance than PTFE

- ◆ It is 18 times more resistant to compression and creep than PTFE

- ◆ Replace the metal spring to reduce the risk caused by the wear of the seal and the contact with the well wall (energy absorbing spring)

In some industries, including the oil and gas industry, the primary use of PEEK is to provide mechanical support for softer sealing materials such as elastomers and fluoropolymers, while in others the properties of this material make it Ideal for use as a primary seal.

Application of PEEK in ESP electric submersible pump (submersible electric pump)

- ◆ Excellent high temperature resistance, excellent insulation even at 250℃

- ◆ Maintains high mechanical strength even at 250℃

- ◆ It still maintains high reliability under high temperature of 200℃ and high pressure of 140MPa for a long time.

- ◆ Excellent high temperature resistance and excellent insulation, even at 250℃, it still maintains high mechanical strength.

Application of PEEK logging instrument: excellent abrasion resistance and insulation

- ◆ It still maintains high reliability under high temperature of 200℃ and high pressure of 140MPa for a long time.

- ◆ Insulators can be used for a long time without being corroded in underground high temperature and strong acid medium (H2S, SO2).

- ◆ Has a unique combination of performance, wear resistance, chemical resistance, mechanical strength, and stable electrical properties over its entire operating temperature range, which helps maintain the integrity of collected data, while bringing electrical Less distraction.

PEEK wire and cable application: excellent high insulation performance

- ◆ Lower water absorption and better toughness than polyimide (PI)

- ◆ Excellent cutting resistance and corrosion resistance to ensure zero electric short circuit

- ◆ Stable chemical corrosion resistance under 200℃ and 100MHz environment

- ◆ Permeability

- ◆ No need to dip insulating varnish like PI wrapping wire, reducing cost

PEEK connector application: improve the overall performance of downhole connectors

- ◆Two times longer life than glass-ceramic connectors

- ◆Twice the power transmission capacity of glass-ceramic connectors

- ◆Excellent insulation performance ensures no leakage

- ◆Excellent resistance to corrosive liquids and gases

- ◆PEEK polymer has high purity and strength, which can allow the design of thinner thin-walled sections in more compact connectors, and can have excellent performance even in small spaces.

- ◆Withstands typical oil and gas industry fluids, including seawater, mineral and silicone oils, and hydraulic fluids, and is also suitable for hydrogen sulfide (H2S) sour gas wells. PEEK performs well above the NORSOK M-710 standard, an important specification for the oil and gas industry.

Other Application

- ● ESP electric submersible pump used: PEEK insulating ring, insulating wire, thrust wear block and front and rear plug four parts

- ● PEEK valve seat, thrust washer and valve stem wear bushing on valve

- ● Used in chemical pumps: magnetic pump isolation sleeve, shaft and lock nut, vane of vane pump.

- ● Used on compressors: piston rings, support rings, valve plates, mushroom bonnets and support pads.

Products

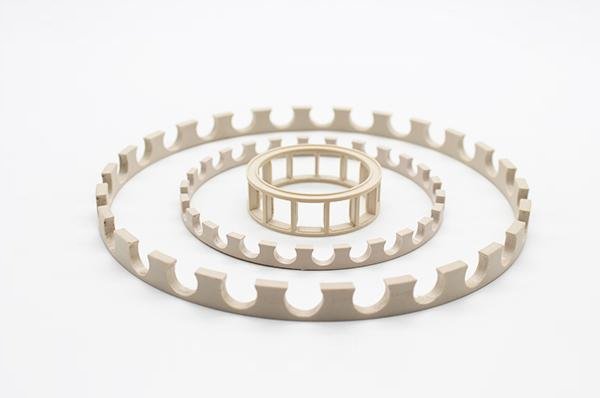

PEEK support seal ring

PEEK gear (transmission control)

PEEK star wheel (single screw compressor)

PEEK bearing cage

PEEK impeller for handheld rechargeable vacuum cleaner

PEEK wear-resistant gear

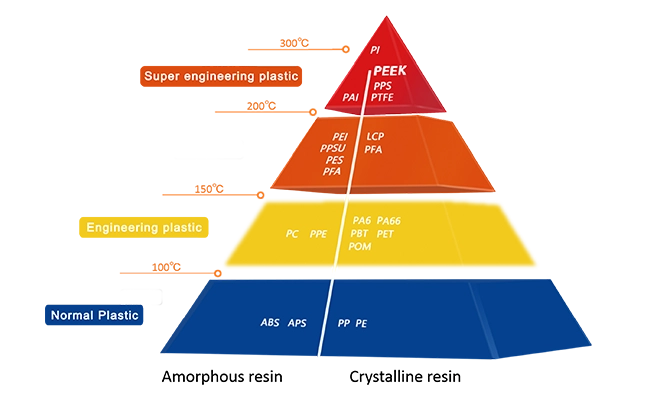

What is PEEK?

PEEK and its modified composite materials show excellent performance under high temperature and high humidity conditions. PEEK have excellent chemical corrosion resistance, self-lubricating, and wear-resistant properties, so it has become the most ideal material to replace copper alloys and ordinary rubber. Compared with them, PEEK has longer service life which can reduce equipment operating costs, improve equipment operating reliability.

High Temperature Performance

PEEK's performance can remain stable in the temperature range from -196°C to 260°C. Under extreme working conditions, it can withstand 300"C for a short time. The performance of PEEK is still reliable even in high temperatures of several kilometers underground work environment.

High Strength and Wear Resistance

Compared with other plastics, PEEK is resistant to compression, impact and also have good fatigue resistance. PEEK is durable in mechanical equipment and wear-resistant environments.

Double the Service Life

PEEK sealing solutions can improve the part service life. Some domestic chemical companies use the PEEK5600FE20 polytetrafluoroethylene modified material designed by JUNHUA PEEK to replace the original material, the service life of the wear parts can even be extended by 1.3-3 times.

Corrosion Resistance

PEEK is chemically inert, and has no reaction to most acids, oils, greases and all other organic and inorganic solvents or enzymes, and can still maintain good strength and dimensional stability.

Self-lubricating

PEEK has low friction coefficient, low running resistance, can be used without oil in some working conditions. The equipment is cleaner, thus improving process reliability, improving energy efficiency and saving costs.

More dom in Design

Injection molds can be used for rapid injection molding of large quantities of complex special-shaped parts, and the cost is low compared to machining.

PEEK Material and Types of it's Modification

PEEK5600G (unfilled PEEK or natural PEEK)

PEEK5600G is one of unfilled or natural PEEK.Outstanding chemical resistance and a high operating temperature (up to 250℃/480F) round out PEEK profile.PEEK5600G has excellent dimensional stability combined with high creep stability, ensuring the suitability of PEEK for the most sophisticated machined parts.

PEEK5600GF30 ( 30% glass fiber filled PEEK)

Compared with unfilled PEEK(PEEK5600G),this 30% glass fiber reinforced PEEK material(PEEK5600GF30) exhibits increased mechanical strength and high rigidity.Plus, improved creep strength and dimensional stability are delivered by the 30% glass fiber filled PEEK.

PEEK5600CF30 (30% carbon fiber filled PEEK)

PEEK5600CF30 is a 30% carbon filled PEEK material that is manufactured by JUNHUA PEEK. Its carbon fiber reinforcement supports the material a high level of rigidity. Carbon fiber reinforced PEEK demonstrates very high mechanical strength values.

PEEK5600LF30( HPV PEEK or bearing grade PEEK)

PEEK5600LF30 black is developed especially for bearing and sliding applications. HPV PEEK is based on a PEEK polymer that has been modified with 10% each of PTFE, graphite and carbon fibres. It combines the properties of a high-grade matrix material with special, wear-improving additives.

Contact Us

Service

JunHua HPP offers one-stop PEEK solutions from design to after-sales, ensuring quality, innovation, and customer satisfaction.

Design and processing

Junhua offers injection molding, machining, and extrusion solutions to optimize design and cost.

Material selection

Junhua specializes in PEEK with multiple grades and recommends the best engineering plastics for your needs.

Measurement

Junhua uses high-precision instruments to provide customers with accurate drawings.

Sampling

Junhua supplies samples for testing and refines designs until approval for mass production.

Mass Production

Junhua controls raw materials, processes, and inspections to ensure consistent product quality.

Quality Control

Junhua follows ISO9001 standards and provides full inspection reports as required.

Improve

Junhua continuously optimizes designs and processes through improvement systems and case experience.

After-sales Service

Junhua offers complete after-sales support to resolve technical issues and protect customer interests.

Junhua Competitiveness

Choosing JunHua means choosing a partner with a complete industrial chain, strong technology research and development capabilities, an efficient production system, strict quality assurance, and excellent customer support.

Industry Deep Dive

18 years of experience in high-performance engineering plastics, serving high-barrier industries such as aerospace and medical, trusted globally.

Complete Industry Chain

From aggregation to processing, a one-stop PEEK solution, simplifying purchases and reducing risks.

Technology Research and Development

12 items of invention patents, 27 items of utility model patents, with collaboration with universities, continuous innovation.

Production Capability

40+ high-efficiency extrusion lines, 500+ professional teams, quick response to global demands.

Quality Assurance

Strict quality control, product traceability from aggregation to processing, three-dimensional detection, COA quality report.

Customer Support

Material selection, mold design, custom processing, and complete after-sales support, becoming your strategic partner.

About Us

Junhua was founded in 2007 and specializes in the development, production, and sale of high-performance engineering plastics, particularly PEEK, PI, PPSU, and other special polymers. The company has a modern factory occupying 15,000+ square meters , with 40+ extrusion lines ,Complete injection molding and CNC processing equipment, with an annual production capacity of over.

We have obtained multiple international certifications such as AS9100D (Aerospace), ISO9001, IATF1649 (Automotive), ISO13485 (Medical Devices), FDA, RoHS, REACH, SGS , and our products are fully traceable . Our customers cover multiple high-threshold industries in over 60 countries and regions , including aerospace, medical, semiconductor, electronics, food, and new energy vehicles. We are committed to becoming a global leader in PEEK solutions.

12 Patents for Invention

27 Utility Model Patents

15,000+㎡ Factory

40+ Extrusion Lines + Cleanroom

60+ Countries

30000+ Global Customers | 3 Billion+ Sales

500+ Team Members

18+ Years of Experience | 40+ Global Employees

Multiple International Certifications

AS9100D / ISO13485 / IATF16949 etc.

1000+ Global Partners

Serve 60+ Countries