Common PEEK Grades and

Properties

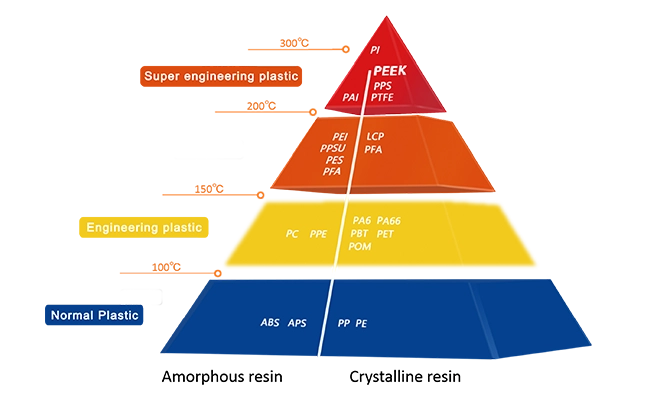

PEEK is a high-temperature

thermoplastic with a high glass transition temperature (143°C) and melting point (343°C), and a heat

deflection temperature under load of up to 316°C (for grades reinforced with 30% glass or carbon

fiber).

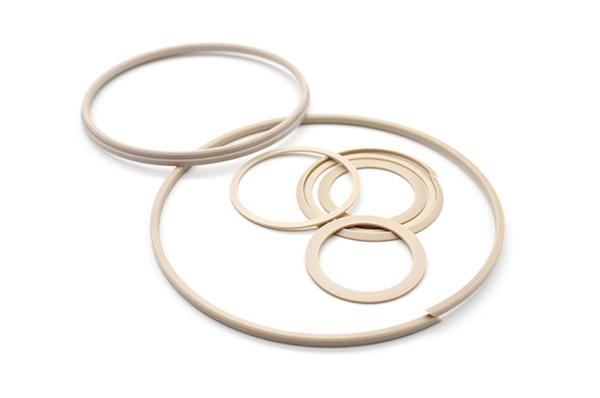

1. PEEK5600G (brown-gray/khaki) is made from pure polyetheretherketone

resin and offers the best toughness and impact resistance of all PEEK grades. Pure PEEK can be

sterilized using convenient methods (steam, dry heat, ethanol, and gamma-rays), and the raw

materials used in its manufacture comply with EU and US FDA food compatibility regulations. These

characteristics make it widely used in the medical, pharmaceutical, and food processing industries.

2. PEEK5600LF30 (black) The addition of PTFE, graphite, and carbon

fiber makes PEEK5600LF30 a bearing-grade plastic. Its superior tribological properties (low

coefficient of friction, wear resistance, and high peak pressure limit) make it an ideal material

for this class of friction applications.

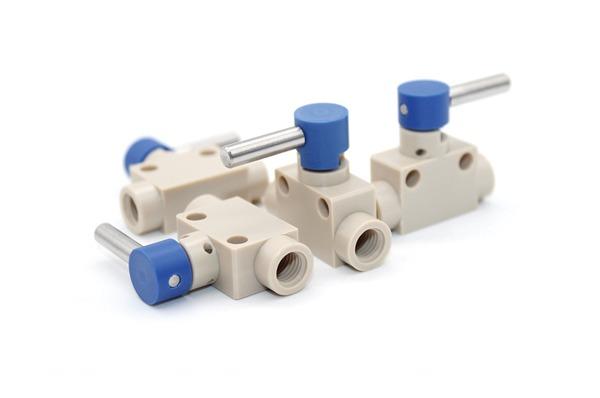

3. PEEK5600GF30 (Brown-Gray): This material is a reinforced grade of

plastic filled with 30% glass fiber. It offers superior rigidity, creep resistance, and dimensional

stability compared to PEEK, making it ideal for structural parts. It can withstand fixed loads for

extended periods at high temperatures. If PEEK5600GF30 is used as a sliding component, its

suitability should be carefully verified, as the glass fiber can scratch mating surfaces.

4. PEEK5600CF30 (Black): This material is reinforced with 30% carbon

fiber. It offers superior mechanical properties (higher elastic modulus, mechanical strength, and

creep resistance) and wear resistance compared to PEEK5600GF30. Furthermore, carbon fiber-reinforced

plastic has 3.5 times the thermal conductivity of unreinforced PEEK, dissipating heat more quickly

from the bearing surface.

*This data is for reference and not a guarantee. For a more detailed

data sheet, please contact our company's technical department.