PEEK – Excellent Performance Across Test & Measurement

Why PEEK is used on analytical instruments instead of stainless steel components?

It is that not only these components must be chemically resistant, but also be made of ultra-pure material to ensure that it does not affect the analytical results, PEEK have all these excellent material proprties. In addition, the high abrasion resistance of peek prevents deformation or breakage of the components, making them more durable and cost-efficient.

JUNHUA® PEEK enables high-precision injection moulded and CNS parts metering with minimum pressure loss, and precision moulding and durability in applications such as ultra-high pressure liquid chromatography, deliver fabrication and end-use efficiencies in laboratory analytical equipment.

Products

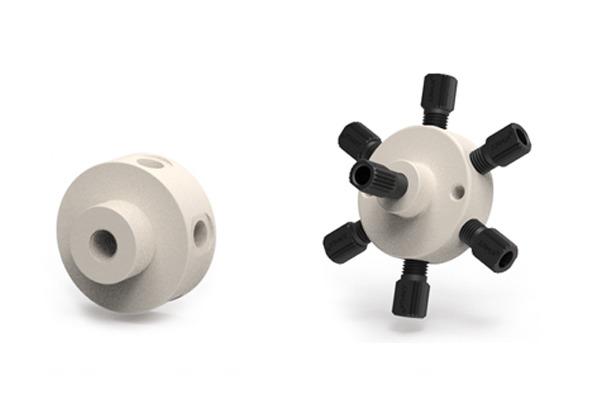

PEEK multi-way

PEEK gem check valve/valve core

PEEK integral high pressure fittings

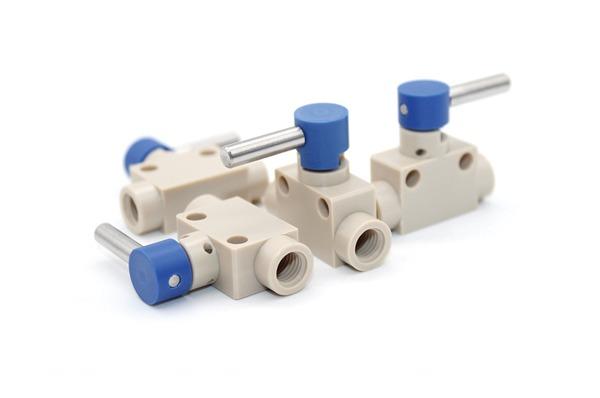

PEEK stop valve

PEEK manual switching valve

PEEK high pressure switching valve

PEEK5600G

Excellent processability and toughness, suitable for thin-walled products.

PEEK5600GF30

High strength and high modulus, suitable for pressure vessels or occasions with high-pressure requirements.

PEEK5600CF30

Carbon fiber reinforced PEEK with excellent mechanical properties.

PEEK5600LF30

With excellent wear resistance, it is suitable for high-speed, high-load applications.

Explore Our PEEK-type Instruments

Our High purity, corrosion resistant and low dissolution PEEK material has been widely used in analytical chromatography equipment, preparative and semi-preparative chromatography equipment, protein purification equipment, IVD equipment, sample pretreatment equipment, pharmaceutical and environmental monitoring equipment and other related equipment.

More then 1000+ related products manufactured by JUNHUA® PEEK are well recognized and selected by our clients of analytical instrument.

Typical product: PEEK Fitting, PEEK Union, PEEK Connector, PEEK plug, PEEK Chromatographic column, PEEK filtering column, PEEK digesting vessel, PEEK tubing, PEEK sampling needle...more details please check below our brochure.

Contact Us

PEEK-type Instruments Case Study

It is that not only these components must be chemically resistant, but also be made of ultra-pure material to ensure that it does not affect the analytical results, PEEK have all these excellent material proprties. In addition, the high abrasion resistance of peek prevents deformation or breakage of the components, making them more durable and cost-efficient.

JUNHUA® PEEK enables high-precision injection moulded and CNS parts metering with minimum pressure loss, and precision moulding and durability in applications such as ultra-high pressure liquid chromatography, deliver fabrication and end-use efficiencies in laboratory analytical equipment.

Product Processing and Quality Control Capability

Cool Jet dry ice deburring equipment lmprove the quality of machined parts

- Non-destructive cleaning;

- Improve product quality and reduce-scrap rate;

- No manual removal of burrs and Haps;

- No secondary waste;

- Faster and more uniform removal of bums and flaps.

100,000-level cleaning workshop

Our company has established a 280-square-meter, 100,000-level cleaning workshop and equipped with 100-level cleaning area accordance with GMP requirements.